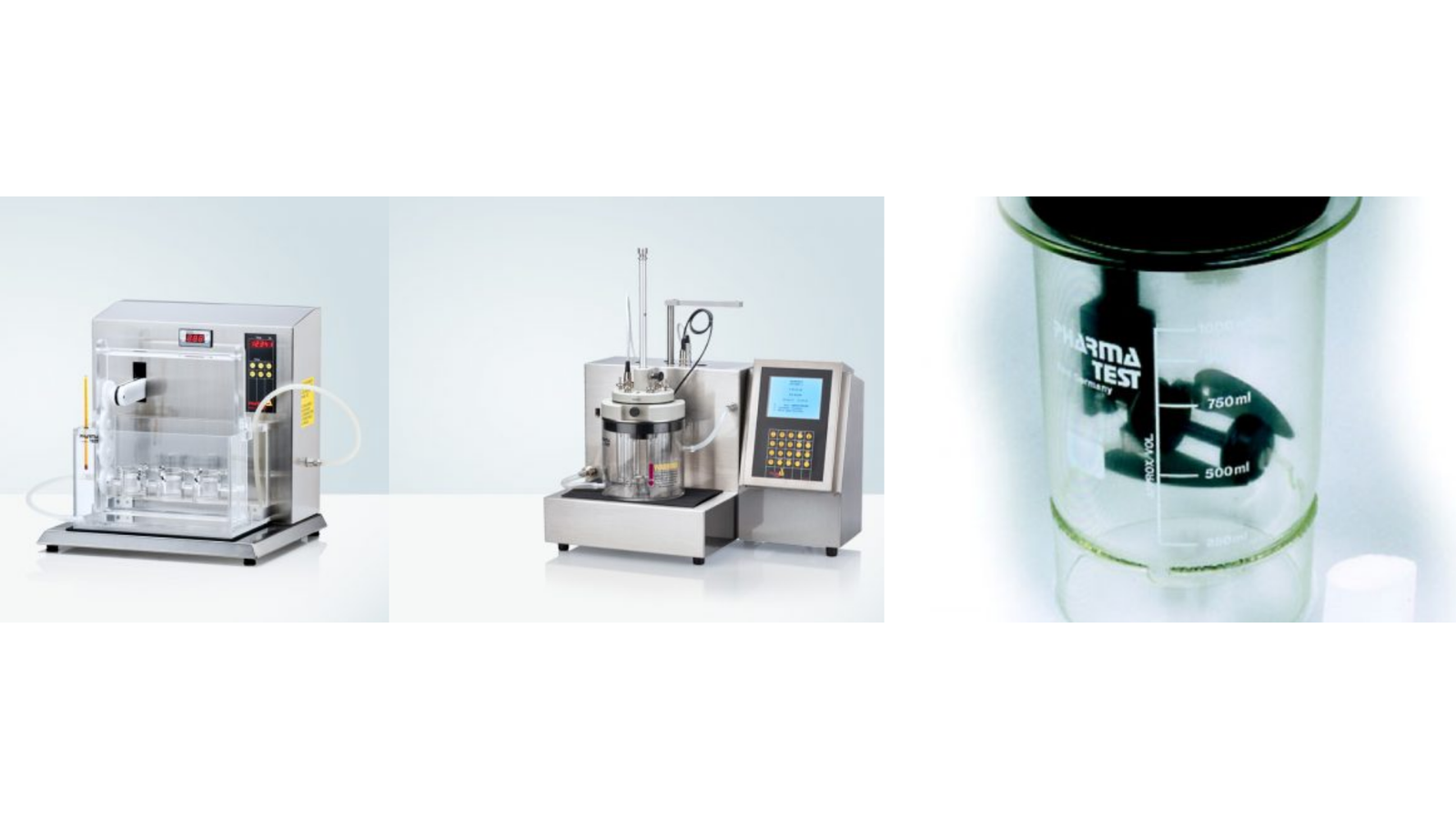

- Tablet Dissolution Testing Instruments

- Offline Automated Dissolution Systems

- Online Automated Dissolution Systems

- In-Situ Dissolution Testing (Coming Soon)

- Media Preparation

- UV/VIS Spectrometers

Tablet Disintegration Testing Instruments

Tablet disintegration testing instruments are widely used in the pharmaceutical industry to evaluate the disintegration characteristics of formulations and the quality control of different dosage forms.

Suppository Testing Instruments

This range of instruments to test the quality of suppositories, pessaries and creams includes disintegration and penetration testers.

Tablet Hardness Testing Instruments

Tablet hardness testing is used to test the breaking point and structural integrity of a tablet prior to storage, transportation, and handling before usage.

Ampoule Testing Instruments

Many liquid drugs are delivered in ampoules.We offer a fully DIN/ISO 9187 compliant solution to test the hardness of empty ampoules at line during production.

Tablet Friability Testing Instruments

Friability testing is used to test the durability of tablets during packing processes and transit. This involves repeatedly dropping a sample of tablets over a fixed time, using a rotating drum with a baffle.

Powder Testing Instruments

The Pharma Test powder testing product portfolio includes instruments to not only measure bulk density but also tap density and flowability.

Leak Testing Instruments

The leak test apparatus is used in the pharmaceutical industry to check the integrity of tablet strips, blister packs and small bottles.

PTZ AUTO EZ

Fully Automated Tablet Disintegration Testing

The fully automated PTZ AUTO EZ instruments are available as single, double, triple and four station models. The instruments automatically detect the individual disintegration times of tablets and other solid dosage forms. Each automated disintegration basket can be operated independently and includes a temperature sensor. They are equipped in full compliance with the USP<701/2040> and EP<2.9.1/2.9.1.2> pharmacopoeia requirements.

Operating Mode

A large LCD screen and an alpha-numerical keyboard are used to edit product and test information, such as the target disintegration time for each station and the bath and media temperatures. Up to 16 different testing methods can be filed in the instrument’s memory. A test screen shows the run time information once a disintegration test is started. The total testing time for the station is displayed at the end of a run. A result report including the individual disintegration times can be printed by connecting a PCL printer to the instrument.

>Fully USP <701/2040> and EP <2.9.1/Test A and B> compliant

>Available as 1, 2, 3 and 4 station instruments

>GMP compliant stainless steel housing

>Equipped for fully-automated operation

>Store up to 16 methods with sample and test information.

ADVANTAGES

>Fully automated detection of individual disintegration end point times

>Select from models with 1, 2, 3 or 4 stations to ideally meet your workload

>Independent movement of all test stations

>Automated lift to raise samples out of the medium at the end of a test

>Integrated method management system

>Excellent access to all vessels

>DQ/QC, IQ and OQ documents included free of charge

| Parameter | Specifications |

|---|---|

| Display | LED backlit LCD, 320×240 pixels, 9″ diagonal, approx. 90x120mm |

| Data Entry | Alpha-numerical keys and function keys |

| Testing Stations | 1, 2, 3 or 4 stations – each independently operateable |

| Testing Time | Programmable from 1 second up to 23h, 59m, 59s |

| Auto Basket Lift | Raises samples out of the medium at test end |

| Security Systems | Password protection for calibration and validation |

| OQ Information | Programmable time sequence information to perform OQ |

| Thermostat | Built-in 1000 W heating tube and circulation pump, water bath temperature programmable from 25.0° – 45.0°C, overheating protection |

| Temperature Accuracy | ± 0.3°C |

| Safety Systems | Pressure switch to protect from overheating (no liquid flow – no heating – no pump); Thermo switch and thermo fuse to protect the heating system in case of electronical fault |

| Stroke Frequency | 30 per minute |

| Stroke Accuracy | ± 1 stroke |

| Stroke Height | 55 mm |

| Stroke Height Accuracy | ± 1 mm |

| Interfaces | RS-232 serial interface for external control and data transfer Parallel PCL printer port (USB printer adapter available) |

| Instrument Dimensions | PTZ AUTO 1EZ approx. 61 x 37 x 54cm (width x depth x height); PTZ AUTO 2EZ approx. 61 x 37 x 54cm (width x depth x height); PTZ AUTO 3EZ approx. 76 x 37 x 54cm (width x depth x height); PTZ AUTO 4EZ approx. 91 x 37 x 54cm (width x depth x height) |

| Packaging Dimensions | PTZ AUTO 1EZ approx. 80 x 51 x 70cm (width x depth x height); PTZ AUTO 2EZ approx. 80 x 51 x 70cm (width x depth x height); PTZ AUTO 3EZ approx. 80 x 51 x 70cm (width x depth x height); PTZ AUTO 4EZ approx. 107 x 77 x 95cm (width x depth x height) |

| Net / Gross Weight | PTZ AUTO 1EZ approx. 24 / 32kg; PTZ AUTO 2EZ approx. 29 / 36kg; PTZ AUTO 3EZ approx. 38 / 53kg; PTZ AUTO 4EZ approx. 46 / 109kg |

| Certification | All components certified to USP / EP requirements |

| CE / EMC Certification | All CE / EMC Certification provided |

| Validation | All IQ & OQ documents included |

Included in the Standard Supply Scope

>One six position “A type” disintegration baskets for each testing station

>One set of six glass tubes for each disintegration basket

>One set of six disintegration disks for each disintegration basket

>One 1 liter glass beaker for each testing station

>One bottle of ALGEX water preservative

>Comprehensive documentation folder including:

>>User manual

>>DQ/QC instrument compliance test certificate

>>IQ documentation

>>OQ documentation

>>Instrument logbook

>>Compliance certificates for baskets, glass tubes and disks

PTZ AUTO

Semi-Automated Tablet Disintegration Testing

The PTZ AUTO disintegration test instruments are available as single, double, triple and four station systems. Each disintegration basket can be operated independently. They are equipped in full compliance with the current USP <701/2040> and EP <2.9.1/2.9.2.1> Pharmacopoeia.

Operating Mode

A large LCD screen and an alpha-numerical keyboard are used to edit product and test information, such as the target disintegration time for each station and the bath and media temperatures. Up to 16 different testing methods can be filed in the instrument’s memory. A test screen shows the run time information once a disintegration test is started. The individual disintegration time of each sample once it was visually detected can be easily logged by pressing the corresponding numeric key. The total testing time for the station is displayed at the end of a run.

>Fully USP <701/2040> and EP <2.9.1/Test A and B> compliant

>Available as 1, 2, 3 and 4 station instruments (PTZ AUTO 1, PTZ AUTO 2, PTZ AUTO 3 and PTZ AUTO 4)

>GMP compliant stainless steel housing

>Upgradeable to fully-automated operation

>Store up to 16 methods with sample and test information

ADVANTAGES

>Select from models with 1, 2, 3 or 4 stations to ideally meet your workload

>Independent movement of all test stations

>Automated lift to raise samples out of the medium at the end of a test

>Automated time log when disintegration is observed

>Integrated method management system

>Excellent access to all vessels

>DQ/QC, IQ and OQ documents included free of charge.

| Parameter | Specifications |

|---|---|

| Display | LED backlit LCD, 320×240 pixels, 9″ diagonal, approx. 90x120mm |

| Data Entry | Alpha-numerical keys and function keys |

| Testing Stations | 1, 2, 3 or 4 stations – each independently operateable |

| Testing Time | Programmable from 1 second up to 23h, 59m, 59s |

| Auto Basket Lift | Raises samples out of the medium at test end |

| Security Systems | Password protection for calibration and validation |

| OQ Information | Programmable time sequence information to perform OQ |

| Thermostat | Water bath temperature programmable from 25.0° – 45.0°C, overheating protection |

| Temperature Accuracy | ± 0.3°C |

| Safety Systems | Pressure switch to protect from overheating (no liquid flow – no heating – no pump); Thermo switch and thermo fuse to protect the heating system in case of electronical fault |

| Stroke Frequency | 30 per minute |

| Stroke Accuracy | ± 1 stroke |

| Stroke Height | 55 mm |

| Stroke Height Accuracy | ± 1 mm |

| Interfaces | RS-232 serial interface for external control and data transfer |

| Instrument Dimensions | PTZ AUTO 1 approx. 61 x 37 x 54cm (width x depth x height); PTZ AUTO 2 approx. 61 x 37 x 54cm (width x depth x height); PTZ AUTO 3 approx. 76 x 37 x 54cm (width x depth x height); PTZ AUTO 4 approx. 91 x 37 x 54cm (width x depth x height) |

| Packaging Dimensions | PTZ AUTO 1 approx. 80 x 51 x 70cm (width x depth x height); PTZ AUTO 2 approx. 80 x 51 x 70cm (width x depth x height); PTZ AUTO 3 approx. 80 x 51 x 70cm (width x depth x height); PTZ AUTO 4 approx. 107 x 77 x 95cm (width x depth x height) |

| Net / Gross Weight | PTZ AUTO 1 approx. 22 / 30kg; PTZ AUTO 2 approx. 29 / 35kg; PTZ AUTO 3 approx. 35 / 45kg; PTZ AUTO 4 approx. 42 / 108kg; |

| Certification | All components certified to USP / EP requirements |

| CE / EMC Certification | All CE / EMC Certification provided |

| Validation | All IQ & OQ documents included |

Included in the Standard Supply Scope

>One six position “A type” disintegration baskets for each testing station

>One set of six glass tubes for each disintegration basket

>One set of six disintegration disks for each disintegration basket

>One bottle of ALGEX water preservative

>Comprehensive documentation folder including

>>User manual

>>DQ/QC instrument compliance test certificate

>>IQ documentation

>>OQ documentation

>>Instrument logbook

>>Compliance certificates for vessels and stirring tools

PTZ-S

The PTZ-S is a manual tablet disintegration testing instrument, manufactured according to the recent USP <701/2040>, EP <2.9.1/2.9.1.2>, JP and other pharmacopoeias. The PTZ-S is used for the manual testing of disintegration times of tablets, capsules and other solid dosage forms.

Operating Mode

The single basket PTZ-S version offers the following features: The illuminated digital LED display shows the elapsed testing time and the firmware version. A silent 24V DC motor drive smoothly moves the disintegration basket up and down over a distance of 55 mm (each way), 30 times per minute. Every two seconds the stroke rate is automatically re-adjusted; the stroke height is pre-set by the eccentric drive mechanism. The disintegration basket which holds the glass tubes and discs, is placed into a stainless steel holder. After start it is smoothly moved into the testing medium.

>Fully USP <701/2040> and EP <2.9.1/2.9.2> compliant

>Temperature adjustable within about 30 to 45°C

>Digital LED display of elapsed testing time and auto stop at the end of a run

>Single and triple station (DIST-3) instruments available

>Exchangeable baskets for apparatus “B” (30mm tube size) as described in the USP <2040> and EP <2.9.1.2>)

>GMP compliant stainless steel housing

ADVANTAGES

>LED display informing of running time and firmware version

>Totally silent operation of the stroke mechanism

>Pre-programmable maximum disintegration time with Auto-Stop function

>Vibration free movement, stroke height set to 55 mm at 30 strokes/min

>Disintegration basket always stops at highest point

>Built-in heating system includes overheating protection

>Small footprint: approx. 42 x 26 x 42cm (width x depth x height)

| Parameter | Specifications |

|---|---|

| Display | LED, illuminated |

| Data Entry | Functional keys |

| Testing Positions | 1 basket for 6 samples (alternative basket for 3 larger samples available) |

| Timer | 1 sec. up to 9 hrs. 59 min. 59 sec. |

| Stroke Height | Fixed at 55mm |

| Stroke Frequency | 30 strokes / minute |

| Temperature Adjustment | Set to 37°C, adjustable by potentiometer between approx. 30° and 45°C |

| Instrument Housing | Stainless steel, powder coated surface for better material protection |

| Instrument Dimensions | Approx. 42 x 26 x 42cm (width x depth x height) |

| Packaging Dimensions | Approx. 60 x 48 x 62cm (width x depth x height) |

| Net / Gross Weight | 12 / 18kg |

| Certification | All components certified to USP/EP requirements |

| CE/EMC Certification | All CE/EMC certification provided |

| Validation | All IQ & OQ documents included |

Included in the Standard Scope of Supply

>Ready to operate including fully equipped disintegration basket, including disks and glass tubes

>1 liter glass beaker

>Thermometer

>Comprehensive documentation folder including: User manual, IQ documentation, OQ documentation, Instrument logbook

DIST-3

Triple Basket Tablet Disintegration Tester

The DIST-3 is a three-basket manual tablet disintegration testing instrument,

manufactured according to the recent USP <701/2040>, EP <2.9.1/2.9.1.2>, JP and other pharmacopoeias. The DIST-3 is used for the manual testing of disintegration times of tablets, capsules and other solid dosage forms.

Operating Mode

The triple basket DIST-3 version offers the following features: The illuminated digital LED display shows the elapsed testing time and the firmware version. A silent 24V DC motor drive smoothly moves the disintegration basket up and down over a distance of 55 mm (each way), 30 times per minute. Every two seconds the stroke rate is automatically re-adjusted; the stroke height is pre-set by the eccentric drive mechanism. The disintegration baskets which hold the glass tubes and discs, are placed into a stainless steel holder. After start they are smoothly moved into the testing medium. Depending on the operating procedure, the test is either automatically stopped if the pre-set time has expired or if the operator aborts the test after he saw all samples to be disintegrated. The baskets always stop at their highest mechanical position.

>Fully USP <701/2040> and EP <2.9.1/2.9.2> compliant

>Temperature adjustable within about 30 to 45°C

>Digital LED display of elapsed testing time and auto stop at the end of a run

>Single (PTZ-S) and triple station instruments available

>Exchangeable baskets for apparatus “B” (30mm tube size) as described in the USP <2040> and EP <2.9.1.2>)

>GMP compliant stainless steel housing

ADVANTAGES

>LED display informing of running time and firmware version

>Totally silent operation of the stroke mechanism

>Pre-programmable maximum disintegration time with Auto-Stop function

>Vibration free movement, stroke height set to 55 mm at 30 strokes/min

>Disintegration basket always stops at highest point

>Built-in heating system includes overheating protection

>Small footprint: approx. 42 x 35 x 42cm (width x depth x height)

| Parameter | Specifications |

|---|---|

| Display | LED, illuminated |

| Data Entry | Functional keys |

| Testing Positions | 3 baskets for 6 samples each (alternative baskets for 3 larger samples available) |

| Timer | 1 sec. up to 9 hrs. 59 min. 59 sec. |

| Stroke Height | Fixed at 55mm |

| Stroke Frequency | 30 strokes / minute |

| Temperature Adjustment | Set to 37°, adjustable by potentiometer between approx. 30° and 45°C |

| Instrument Housing | Stainless steel, powder coated surface for better material protection |

| Instrument Dimensions | Approx. 42 x 35 x 42cm (width x depth x height) |

| Packaging Dimensions | Approx. 60 x 48 x 62cm (width x depth x height) |

| Net / Gross Weight | 18 / 24kg |

| Certification | All components certified to USP/EP requirements |

| CE/EMC Certification | All CE/EMC certification provided |

| Validation | All IQ & OQ documents included |

>Ready to operate including three fully equipped disintegration baskets, including disks and glass tubes

>Three 1 ltr. glass beakers

>Thermometer

>Comprehensive documentation folder including:

>>User manual

>>IQ documentation

>>OQ documentation

>>Instrument logbook

PT-ODF

Disintegration Basket Add-On to Test Orodispersible Films

Orodispersible films (ODF) are a novel dosage form. Since 2012, they are monographed in European Pharmacopoeia (Ph.Eur. 7.4). Despite the fact that there are several film products available on the market, there has been no specific test method defined to characterize this dosage form.

The PT-ODF test basket for the PTZ AUTO EZ tablet disintegration testing instruments closes this gap by offering a simple and affordable device to reliably test the disintegration times of films. The PT-ODF basket can be used with any existing Pharma Test PTZ AUTO EZ instrument without any need for modification. It is attached directly to the PT-MKT electronic test baskets.

>Disintegration basket add-on to test the disintegration time of orodispersible films

>Test six samples per basket (PT-ODF6) or three larger samples (PT-ODF3)

>Add-on is connected to a PT-MKT electronic disintegration basket

>The test is performed with a PTZ AUTO EZ disintegration testing instrument

ADVANTAGES

>A robust method to determine disintegration time of orodispersible films

>Simple add-on system makes this a low cost upgrade from a standard PTZ AUTO EZ tablet disintegration testing instrument

>PT-ODF basket add-on can be installed and removed easily and quickly

| Parameter | Specifications |

|---|---|

| Clamp Weight | 3g |

| Testing Positions | PT-ODF6: 6 per basket; PT-ODF3: 3 per basket |

The PTZ-S is a manual tablet disintegration testing instrument, manufactured according to the recent USP <701/2040>, EP <2.9.1/2.9.1.2>, JP and other pharmacopoeias. The PTZ-S is used for the manual testing of disintegration times of tablets, capsules and other solid dosage forms.

Operating Mode

The single basket PTZ-S version offers the following features: The illuminated digital LED display shows the elapsed testing time and the firmware version. A silent 24V DC motor drive smoothly moves the disintegration basket up and down over a distance of 55 mm (each way), 30 times per minute. Every two seconds the stroke rate is automatically re-adjusted; the stroke height is pre-set by the eccentric drive mechanism. The disintegration basket which holds the glass tubes and discs, is placed into a stainless steel holder. After start it is smoothly moved into the testing medium.

>Fully USP <701/2040> and EP <2.9.1/2.9.2> compliant

>Temperature adjustable within about 30 to 45°C

>Digital LED display of elapsed testing time and auto stop at the end of a run

>Single and triple station (DIST-3) instruments available

>Exchangeable baskets for apparatus “B” (30mm tube size) as described in the USP <2040> and EP <2.9.1.2>)

>GMP compliant stainless steel housing

ADVANTAGES

>LED display informing of running time and firmware version

>Totally silent operation of the stroke mechanism

>Pre-programmable maximum disintegration time with Auto-Stop function

>Vibration free movement, stroke height set to 55 mm at 30 strokes/min

>Disintegration basket always stops at highest point

>Built-in heating system includes overheating protection

>Small footprint: approx. 42 x 26 x 42cm (width x depth x height)

| Parameter | Specifications |

|---|---|

| Display | LED, illuminated |

| Data Entry | Functional keys |

| Testing Positions | 1 basket for 6 samples (alternative basket for 3 larger samples available) |

| Timer | 1 sec. up to 9 hrs. 59 min. 59 sec. |

| Stroke Height | Fixed at 55mm |

| Stroke Frequency | 30 strokes / minute |

| Temperature Adjustment | Set to 37°C, adjustable by potentiometer between approx. 30° and 45°C |

| Instrument Housing | Stainless steel, powder coated surface for better material protection |

| Instrument Dimensions | Approx. 42 x 26 x 42cm (width x depth x height) |

| Packaging Dimensions | Approx. 60 x 48 x 62cm (width x depth x height) |

| Net / Gross Weight | 12 / 18kg |

| Certification | All components certified to USP/EP requirements |

| CE/EMC Certification | All CE/EMC certification provided |

| Validation | All IQ & OQ documents included |

Included in the Standard Scope of Supply

>Ready to operate including fully equipped disintegration basket, including disks and glass tubes

>1 liter glass beaker

>Thermometer

>Comprehensive documentation folder including: User manual, IQ documentation, OQ documentation, Instrument logbook

The PTZ-S is a manual tablet disintegration testing instrument, manufactured according to the recent USP <701/2040>, EP <2.9.1/2.9.1.2>, JP and other pharmacopoeias. The PTZ-S is used for the manual testing of disintegration times of tablets, capsules and other solid dosage forms.

Operating Mode

The single basket PTZ-S version offers the following features: The illuminated digital LED display shows the elapsed testing time and the firmware version. A silent 24V DC motor drive smoothly moves the disintegration basket up and down over a distance of 55 mm (each way), 30 times per minute. Every two seconds the stroke rate is automatically re-adjusted; the stroke height is pre-set by the eccentric drive mechanism. The disintegration basket which holds the glass tubes and discs, is placed into a stainless steel holder. After start it is smoothly moved into the testing medium.

>Fully USP <701/2040> and EP <2.9.1/2.9.2> compliant

>Temperature adjustable within about 30 to 45°C

>Digital LED display of elapsed testing time and auto stop at the end of a run

>Single and triple station (DIST-3) instruments available

>Exchangeable baskets for apparatus “B” (30mm tube size) as described in the USP <2040> and EP <2.9.1.2>)

>GMP compliant stainless steel housing

ADVANTAGES

>LED display informing of running time and firmware version

>Totally silent operation of the stroke mechanism

>Pre-programmable maximum disintegration time with Auto-Stop function

>Vibration free movement, stroke height set to 55 mm at 30 strokes/min

>Disintegration basket always stops at highest point

>Built-in heating system includes overheating protection

>Small footprint: approx. 42 x 26 x 42cm (width x depth x height)

| Parameter | Specifications |

|---|---|

| Display | LED, illuminated |

| Data Entry | Functional keys |

| Testing Positions | 1 basket for 6 samples (alternative basket for 3 larger samples available) |

| Timer | 1 sec. up to 9 hrs. 59 min. 59 sec. |

| Stroke Height | Fixed at 55mm |

| Stroke Frequency | 30 strokes / minute |

| Temperature Adjustment | Set to 37°C, adjustable by potentiometer between approx. 30° and 45°C |

| Instrument Housing | Stainless steel, powder coated surface for better material protection |

| Instrument Dimensions | Approx. 42 x 26 x 42cm (width x depth x height) |

| Packaging Dimensions | Approx. 60 x 48 x 62cm (width x depth x height) |

| Net / Gross Weight | 12 / 18kg |

| Certification | All components certified to USP/EP requirements |

| CE/EMC Certification | All CE/EMC certification provided |

| Validation | All IQ & OQ documents included |

Included in the Standard Scope of Supply

>Ready to operate including fully equipped disintegration basket, including disks and glass tubes

>1 liter glass beaker

>Thermometer

>Comprehensive documentation folder including: User manual, IQ documentation, OQ documentation, Instrument logbook