Mass Comparators

- Laboratory Balance

- Industrial Scale

- Scales for EX areas

- Medical Scales

- PGC Scales

- Checkweighers

- Indicators and Terminals

- Weighing modules

- Mass comparators

- Environmental protection

- Pipetting

- Pharma and Biotech solutions

- Stent weighing

- Mass Standards

- Weighing tables

- Metal detectors

- Weighing platforms

- Medical Scales

Automatic Mass Comparators

AVK-1000 Automatic Vacuum Mass Comparator

RADWAG-manufactured AVK-1000 automatic vacuum mass comparator is intended for national metrological institutes that transport and maintain the national reference mass standard of 1 kg.

The comparator is intended for weighing mass standards and silicone spheres of 100 mm diameter. It enables comparison of up to 6 prototypes of max 1kg mass. The repeatability of the process is of 0.3 µg and readability of d = 0.1 µg.

A specially designed vacuum chamber enables carrying out measurements in a vacuum of 10-6 mbar capacity or in atmosphere containing noble gases.

AVK-1000 is equipped with suspended weighing pan that eliminates eccentricity errors.

Standard version of the mass comparator features thermo-hygro-barometer for testing ambient conditions with great accuracy: pressure of 0.001hPa, humidity of 0.01% and temperature of 0.001 °C.

The comparator is also equipped with high quality vacuum gauge.

The AVK-1000 vacuum mass comparator can be equipped with the LOAD LOCK system for carrying mass standards. The system enables switching or adding artefacts without changing the atmosphere inside the main chamber. With the use of a special chamber for mass standards switching the whole process is 90% shorter.

During mass standards replacement carried out without the use of the LOAD LOCK system, the air enters the main chamber of the mass comparator. After each opening of the chamber it is necessary to pump the air out in order to obtain required vacuum value. The vacuum mass comparator needs approx. 48 hours in order to obtain vacuum that ensures measurement repeatability.

The LOAD LOCK is equipped with a high-efficiency pump system, the time of pumping the air out in order to enable opening of the valve of the main chamber is significantly shortened. The stabilization of the main chamber after replacing/adding the mass standard and closing the valve connecting the main chamber and the LOAD LOCK system takes 5 hours.

The high-quality vacuum gauges enable monitoring and comparing the vacuum value in order to determine the moment when opening the valve again and replacing the mass standard is available. A specially designed viewfinder enables monitoring of the process.

The LOAD LOCK enables switching objects of dimensions adapted to the AVK-1000 mass comparator: cylindrical mass standards of 22-95 mm diameter and silicone spheres of 40-100 mm diameter.

Supplementing the AVK-1000 vacuum mass comparator with LOAD LOCK system significantly improves the comparison performance.

| E1 |

100 g — 1 kg

|

| E2 |

100 g — 1 kg

|

| F1 |

100 g — 1 kg

|

| F2 |

100 g — 1 kg

|

| Maximum capacity [Max] |

1002 g |

| Readability [d] |

0.1 µg |

| Standard repeatability [5% Max] |

0.4 µg |

| Standard repeatability [Max] |

0.5 µg |

| Permissible repeatability |

1 µg |

| Electric compensation range |

-1 g — +2 g

|

| Stabilization time |

60 s |

| Adjustment |

external

|

| Supplementary weights external |

500 g, 800 g, 900 g

|

| Magazine positions |

6

|

| Weighing pan dimensions |

ø100 mm |

| Vacuum chamber dimensions |

965×745×1150 mm |

| Pressure range |

10(⁻⁶) mbar

|

| Object diameters |

cylindryczne ø (22-95)x110; kuliste ø (40-100) mm |

| Weighing device dimensions |

965×745×1700 mm |

| Controling device dimensions |

206×140×70 mm |

| Net weight (without table) |

250 kg |

| Net weight (with table) |

650 kg |

| Power supply |

100 — 240 V AC 50 / 60 Hz

|

| Operating temperature |

+15 — +30 °C |

| Operating temperature change rate |

±0.1°C/12h

|

| Relative humidity |

45% — 60%

|

Density Measurement

AGV-2/20 Automatic Comparator

The AGV-2/20 automatic comparator determines density and volume of mass standards of class E1 and lower in accordance with OIML R111. It is characterized by the highest accuracy and measurement stability ranging between 1 kg to 20 kg.

The comparator features specially designed feeder to load and unload the magazine with mass standards. The device is equipped with an additional circulator eliminating air bubbles and a top-class liquid temperature sensor of 0.001 ˚C accuracy. A weighing pan suspended on wires eliminates the eccentricity and minimizes the influence of liquid surface tension.

Dedicated software enables to determine mass standards density and calculate uncertainty using A method according to OIML R111. It also allows to determine (verify) liquid density.

| E1 |

1 kg — 20kg/ 1 g — 1 kg

|

| E2 |

1 kg — 20kg/ 1110g

|

| F1 |

1 kg — 20kg

|

| F2 |

1 kg — 20kg

|

| Maximum capacity [Max] |

26.1kg – 1110g |

| Readability [d] |

1mg – 0.05mg |

| Standard repeatability [5% Max] |

2mg – 0.04 mg |

| Standard repeatability [Max] |

3mg – 0.05mg |

| Permissible repeatability |

6mg – 0.08mg |

| Electric compensation range |

100 g — +26.1 kg – (-10 g — +110)g

|

| Stabilization time |

30s |

| Adjustment |

external

|

| Magazine positions |

automatic 2 positions

|

| Weighing pan dimensions |

ø220 self centering mm |

| Object diameters |

25-145mm |

| Power supply |

100 — 240 V AC 50 / 60 Hz

|

| Operating temperature |

+15 — +30 °C |

| Storage temperature |

-20 — +50 °C |

| Operating temperature change rate |

±0.5°C/12h (±0.3°C/4h)

|

| Relative humidity |

40% — 60%

|

| Relative humidity change rate |

±5%/12h (3%/4h)

|

Robotic Mass Comparator

RMCM 5 Robotic Mass Comparator

- reduction of air drafts and vibrations from a robotic system in the course of comparison,

- minimised risk of human error,

- easier maintaining of stable environmental conditions inside the weighing chamber (thanks to a compact device dimensions).

| E1 | 1 mg — 5 g /10 g — 1000g

|

| E2 | 1 mg — 5 g/10 g — 1000g

|

| F1 | 1 mg — 5 g/10 g — 1000g

|

| F2 | 1 mg — 5 g/10 g — 1000g

|

| Maximum capacity [Max] | 5.1g – 1060g |

| Readability [d] | 0.1µg – 1µg |

| Standard repeatability [5% Max] | 0.25µg – 1.2µg |

| Standard repeatability [Max] | 0.4µg – 2µg |

| Permissible repeatability | 0.7µg – 5µg |

| Electric compensation range | 0 — +5.1 g – (-1 g — +10)g

|

| Stabilization time | 30s |

| Adjustment | internal (automatic)

|

| Magazine positions | 120

|

| Weighing pan dimensions | 24×50mm – 50×125mm |

| Communication interface | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±0.5°C/12h (±0.3°C/4h)

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ±5%/12h (3%/4h)

|

Automatic Mass Comparators

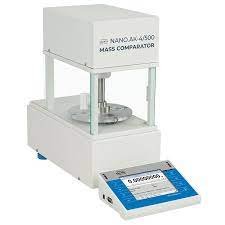

Nano-Comparator NANO.AK-4/500

Effective and Excellent Measurement

The NANO.AK-4/500 automatic nano mass comparator enables determining mass deviations of weights with the minimum possible operator participation. The comparator allows to compare weights of mass ranging between 0.05 mg to 500 mg.

Excellent Measurement Repeatability

NANO.AK-4/500 automatic nano mass comparator, due to the elimination of the human factor, temperature changes and air drafts, guarantees excellent measurement repeatability when compared to manual mass comparator.

Design and Functionality

An element that controls mass comparator operation is a digital management module, which is placed inside comparator’s chamber along with an automatic mass standard feeder. Mass comparator is operated by means of indicator connected to the comparator controller. Control elements are not mechanically integrated with the construction thanks to what the influence of ambient conditions on mass comparator chamber is significantly reduced.

Dedicated Software

Specially designed RMCS computer software enables comprehensive realisation of calibration procedures in laboratory. The system manages the whole calibration process, starting from the moment the order is placed, through proced

| E1 | 0.05 mg — 500 mg

|

| E2 | 0.05 mg — 500 mg

|

| F1 | 0.05 mg — 500 mg

|

| F2 | 0.05 mg — 500 mg

|

| Maximum capacity [Max] | 51 mg |

| Readability [d] | 10 ng

|

| Standard repeatability [5% Max] | 0.04 µg |

| Standard repeatability [Max] | 0.06 µg |

| Permissible repeatability | 0.1 µg |

| Eccentricity (tested load) | 0mg |

| Electric compensation range | 0 — 510 mg

|

| Stabilization time | 30s |

| Adjustment | external

|

| Supplementary weights internal | –

|

| Supplementary weights external | –

|

| Magazine positions | 4

|

| Weighing pan dimensions | ø20mm |

| Weighing device dimensions | 385×245×390mm |

| Controling device dimensions | 460×250×195mm |

| Packaging dimensions | 860×750×570mm |

| Net weight | 20kg |

| Gross weight | 30kg |

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±0.5°C/12h (±0.3°C/4h)

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ±5%/12h (3%/4h)

|

UMA Automatic Mass Comparator

Mass comparators of UMA 5 series stand for the highest standard of professional automatic mass comparators.

They provide comparison of 1 mg – 5 g weights of E1 and lower classes.

The device is equipped with 36 magazine positions allowing to deposit up to 36 weights. This solution allows to perform either comparison for complete set of weights carried out within one process or comparison for just a few weights of the same mass.

Owing to elimination of human factor and with temperature changes and air drafts reduced to zero, UMA automatic mass comparators provide the highest possible measurement repeatability.

| E1 | 1 mg — 5 g /100 g — 1000 g

|

| E2 | 1 mg — 5 g/10 g — 1000 g

|

| F1 | 1 mg — 5 g/10 g — 1000 g

|

| F2 | 1 mg — 5 g/10 g — 1000 g

|

| Maximum capacity [Max] | 5.1 g – 1060g |

| Readability [d] | 0.0001mg – 0.005mg |

| Standard repeatability [5% Max] | 0.2µg – 8µg |

| Standard repeatability [Max] | 0.4µg – 12µg |

| Permissible repeatability | 0.6µg – 20µg |

| Eccentricity (tested load) | 0µg |

| Electric compensation range | 0 — +5.1 g

|

| Stabilization time | 30s |

| Adjustment | internal (automatic)

|

| Supplementary weights internal | –

|

| Supplementary weights external | –

|

| Magazine positions | 36

|

| Weighing pan dimensions | ø20mm – ø48mm |

| Weighing device dimensions | 950 ×590×540 mm |

| Controling device dimensions | 460×250×195 mm |

| Packaging dimensions | 1200×800×950mm |

| Net weight | 101.5kg – 115kg |

| Gross weight | 182.5kg – 205kg |

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±0.5°C/12h (±0.3°C/4h)

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ±5%/12h (3%/4h)

|

AK-4 Automatic Mass Comparator

Application:

Automatic mass comparator AK-4/1000 series is intended to automatic determination of weights mass deviations with operator’s activity limited to the minimum. The comparator enables determining deviations of three tested weights in a single cycle. AK-4/1000 is designed to compare weights from 100 g to 1 kg. The instrument is commonly applicable in mass measuring laboratories, and particularly in certification units for weights classes E and F.

Design and functionality:

The supervising part of the mass comparator is a digital module which cooperates with a controller of instrument’s mechanical components. The digital module and the automatic loader are located in mass comparator’s weighing chamber. The instrument is operated by means of digital display which is plugged to mass comparator’s controller. The supervising elements are not integrated with mass comparator’s mechanical parts, thus enabling separation of instrument’s weighing chamber from ambient conditions influence.

| E1 | 100 g — 1 kg/10 g — 100 g

|

| E2 | 100 g — 1 kg/10 g — 100 g

|

| F1 | 100 g — 1 kg/10 g — 100g

|

| F2 | 100 g — 1 kg/10 g — 100 g

|

| Maximum capacity [Max] | 1.02kg – 110 g |

| Readability [d] | 0.005mg – 0.001mg |

| Standard repeatability [5% Max] | 8µg- 1.5 µg |

| Standard repeatability [Max] | 15µg – 2µg |

| Permissible repeatability | 2.5µg – 3.5µg |

| Eccentricity (tested load) | 0mg |

| Electric compensation range | -10 g — +20 g

|

| Stabilization time | 30 s |

| Adjustment | external

|

| Supplementary weights internal | half automatic

|

| Supplementary weights external | –

|

| Magazine positions | 4

|

| Weighing pan dimensions | ø50mm – ø24mm |

| Weighing device dimensions | 385×215×600mm |

| Controling device dimensions | 206×140×70mm |

| Anti-draft chamber dimensions | 560×340×665mm |

| Packaging dimensions | 860×800×560mm |

| Chamber packaging size | 950×420×630mm |

| Net weight | 46.8kg |

| Gross weight | 66.8kg |

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±0.5°C/12h (±0.3°C/4h)

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ±5%/12h (3%/4h)

|

AKM-2 Automatic Mass Comparator

Application:

Mass comparator AKM-2 series featuring automatic mass loader enables automatic determination of mass deviations of a single weight in a single cycle. The system of automatic mass comparator is commonly applicable in mass measuring laboratories, and particularly in certification units for weights classes E, F and M.

Design and functionality:

The supervising part of a mass comparator is a digital module which cooperates with a controller of instrument’s mechanical components. The automatic mass loader features a basis with self-centring fields, a robot and a steel body. The digital module and the robot are located in mass comparator’s weighing chamber. The loading robot is controlled by the computer’s controller. The instrument is operated by means of digital display which is plugged to mass comparator’s controller.

Lengthwise shift of the loading robot with weights is carried out automatically using solenoid actuators. Additional software functions enable loading and taking off the weights, data processing and storing, and data export to instrument’s memory.

| E1 | 2 kg — 10 kg/20 kg — 50 kg

|

| E2 | 500 g — 10 kg/5 kg — 50 kg

|

| F1 | 500 g — 10 kg/5 kg — 50 kg

|

| F2 | 500 g — 10 kg/5 kg — 50 kg

|

| Maximum capacity [Max] | 10.2kg- 51kg |

| Readability [d] | 0.1mg-1mg |

| Standard repeatability [5% Max] | 0.15mg – 2.5mg |

| Standard repeatability [Max] | 0.2mg – 3.5mg |

| Permissible repeatability | 0.35mg – 5mg |

| Eccentricity (tested load) | 0 mg |

| Electric compensation range | -100 g — +200 g

|

| Stabilization time | 30s |

| Adjustment | external

|

| Supplementary weights internal | half automatic

|

| Supplementary weights external | –

|

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±0.5°C/12h (±0.3°C/4h)

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ±5%/12h (3%/4h)

|

| Weighing pan dimensions | ø90mm – ø100mm |

| Weighing device dimensions | 950×650×1150mm – 1050×650×1150mm |

| Controling device dimensions | 206×140×70mm |

| Packaging dimensions | 1050×800×1320mm |

| Net weight | 230kg – 260kg |

| Net weight | 230kg – 260kg |

| Gross weight | 350kg – 380kg |

| Gross weight | 350kg – 380kg |

Manual Mass Comparators

UYA.4Y.KO Manual Mass Comparator

The newest line of Radwag mass comparators enables adjusting mass standards and weights according to the OIML recommendations (R-111) from 1mg to 5 g in class E1 and lower.

Mass comparators are used for both, ensuring traceability of mass measurements and verification of weights in accordance with the principles of legal metrology. RADWAG Mass Comparators have gained recognition among Accredited Calibration Laboratories in many countries.

The standard equipment of the UYA 5.4Y.KO mass comparator is an anti-draft chamber eliminating imperfect conditions in weighing rooms (air drafts). The mass comparator is placed inside the anti-draft chamber. Sliding side panes enable easy access to the weighing chamber.

Mass comparator UYA 4Y.KO series, comprises two components. One of them holds the electronic module, and the other precise mechanical measuring system. Such solution guarantees elimination of temperature influence (warming of electronic elements) on the comparator’s indications. The comparator features an aesthetic, cylindrically shaped weighing chamber with glass draft shield and automatic door opening system. All elements of the weighing chamber are manufactured from glass or metal to minimize the influence of electrostatic charges on the measuring result.

In order to carry out the weighing process by means of microbalance and ultra-microbalances correctly, it is necessary to prepare the workstation and to operate the device as required.

Usage and installation guidelines are to found in the following document: Installation and usage conditions for ultra-microbalances and microbalances.

| E1 | 1 mg — 5 g

|

| E2 | 1 mg — 5 g

|

| F1 | 1 mg — 5 g

|

| F2 | 1 mg — 5 g

|

| M1 | 1 mg — 5 g

|

| M2 | 1 mg — 5 g

|

| Maximum capacity [Max] | 5.1 g |

| Readability [d] | 0.1 µg |

| Standard repeatability [5% Max] | 0.2 µg |

| Standard repeatability [Max] | 0.4 µg |

| Permissible repeatability | 0.6 µg |

| Eccentricity (tested load) | 1d / 1 mm

|

| Electric compensation range | 0 — 5.1 g

|

| Stabilization time | 30 s |

| Adjustment | internal (automatic)

|

| Supplementary weights internal | –

|

| Supplementary weights external | –

|

| Communication interface | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±0.5°C/12h (±0.3°C/4h)

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ± 2 % / 4 h

|

| Weighing pan dimensions | ø16 mm |

| Weighing device dimensions | 370×160×175 mm |

| Controling device dimensions | 206×140×70 mm |

| Anti-draft chamber dimensions | 560×350×255 mm |

| Packaging dimensions | 660×660×455 mm |

| Chamber packaging size | 820×840×630 mm |

| Net weight | 9.1 kg |

| Gross weight | 16.6 kg |

XA.4Y.A.KO Manual Mass Comparator

The newest line of Radwag Mass Comparators enables adjusting mass standards and weights according to the OIML recommendations (R-111) from 1 mg to 200 g for F2 class and lower.

The comparators are used both for ensuring traceability of mass measurements, and verification of weights in accordance with the principles of legal metrology. RADWAG Mass Comparators have gained recognition among Accredited Calibration Laboratories in many countries.

Mass comparator XA 4Y.A.KO series comprises two components. One of them holds the electronic module, and the other precise mechanical measuring system.

The comparator features an aesthetic, large weighing chamber and a glass draft shield in one. Its asset is an automatic door opening system. The XA 4Y.A.KO series features an intuitive menu supporting a user in instrument operation.

| E1 | 100 mg — 5 g/200 g

|

| E2 | 1 mg — 5 g/50 g — 200 g

|

| F1 | 1 mg — 5 g/50 mg — 200 g

|

| F2 | 1 mg — 5 g/1 mg — 200 g

|

| M1 | 1 mg — 5 g/1 mg — 200 g

|

| M2 | 1 mg — 5 g/1 mg — 200 g

|

| Maximum capacity [Max] | 6g- 210g |

| Readability [d] | 0.001mg – 0.01mg |

| Standard repeatability [5% Max] | 1.2µg – 0.005mg |

| Standard repeatability [Max] | 2µg – 0.025mg |

| Permissible repeatability | 3µg – 0.05mg |

| Eccentricity (tested load) | 1d / 1 mm

|

| Electric compensation range | 0 — 6 g/ 0 — 210 g

|

| Stabilization time | 5s |

| Adjustment | internal (automatic)

|

| Communication interface | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +35 °C |

| Operating temperature change rate | ±1°C/12h

|

| Relative humidity | 40% — 70%

|

| Relative humidity change rate | ±5%/4h

|

| Weighing pan dimensions | ø16 – ø90

|

| Weighing device dimensions | 564×253×300mm |

| Controling device dimensions | 206×140×70mm |

| Packaging dimensions | 720×385×485mm |

| Net weight | 14.7kg |

| Gross weight | 19.1kg |

WAY.4Y.KO Manual Mass Comparator

The newest line of Radwag Mass Comparators enables adjusting mass standards and weights according to the OIML recommendations (R-111) from 1 mg to 5 kg for E1 class and lower.

Mass comparators are used both for ensuring traceability of mass measurements, and verification of weights in accordance with the principles of legal metrology. RADWAG Mass Comparators have gained recognition among Accredited Calibration Laboratories in many countries.

Mass comparator WAY 4Y.KO series similarly to other models, comprises two components. One of them holds the electronic module, and the other precise mechanical measuring system.

The WAY 4Y.KO series comes standard with an aesthetic, large weighing chamber with glass anti-draft shield. All elements of the weighing chamber are manufactured from glass or metal to minimize the influence of electrostatic charges on weighing result. Mass comparator WAY 4Y.KO series features an intuitive menu supporting a user while operating the instrument.

| E1 | 500 g — 1 kg

|

| E2 | 100 g — 1 kg

|

| F1 | 10 g — 1 kg/ 5kg

|

| F2 | 1 g — 1 kg/ 2 g — 5 kg

|

| M1 | 1 g — 1 kg/500 g — 5 kg

|

| M2 | 1 g — 1 kg/200 g — 5 kg

|

| Maximum capacity [Max] | 1.02kg -5100g |

| Readability [d] | 0.01mg – 1mg |

| Standard repeatability [5% Max] | 0.25mg – 0.8mg |

| Standard repeatability [Max] | 0.03mg – 1mg |

| Permissible repeatability | 0.05mg – 2mg |

| Eccentricity (tested load) | 1d / 1 mm – 1d / 5 mm

|

| Electric compensation range | -10 g — +20 g

|

| Stabilization time | 30s |

| Adjustment | external

|

| Supplementary weights internal | half automatic

|

| Supplementary weights external | 50 g, 30 g, 2× 10 g

|

| Communication interface | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±0.5°C/12h (±0.3°C/4h)

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ± 3 % / 4 h

|

| Weighing pan dimensions | ø60mm – ø100mm |

| Weighing device dimensions | 385×215×525mm |

| Controling device dimensions | 206×140×70mm |

| Anti-draft chamber dimensions | 660×470×700mm |

| Packaging dimensions | 860×800×550mm |

| Chamber packaging size | 820×850×630mm |

| Net weight | 37kg |

| Gross weight | 57kg |

PM.4Y.KB Manual Mass Comparator

The newest line of Radwag Mass Comparators enables adjusting mass standards and weights according to the OIML recommendations (R-111) from 1 kg to 50kg for F2 class and lower.

The comparators are used both for ensuring traceability of mass measurements, and verification of weights in accordance with the principles of legal metrology. RADWAG Mass Comparators have gained recognition among Accredited Calibration Laboratories in many countries.

Mass comparator PM 4Y.KB series comprises two components. One of them holds the electronic module, and the other precise mechanical measuring system.

High measuring accuracy is guaranteed by semi-automatic adjustment system with external mass standard. The weighing pan is made of aluminium and features holders for centering the tested mass standard. The PM 4Y.KB series features an intuitive menu supporting a user while operating the instrument.

| E1 | –

|

| E2 | –

|

| F1 | 20 kg

|

| F2 | 5 kg — 20 kg/50 kg

|

| M1 | 2 kg — 25 kg/ 10 kg — 50 kg

|

| M2 | 1 kg — 25 kg/ 5 kg — 50 kg

|

| Maximum capacity [Max] | 25.5kg – kg |

| Readability [d] | 10mg – 100mg |

| Standard repeatability [5% Max] | 8mg – 70mg |

| Standard repeatability [Max] | 15mg – 100mg |

| Permissible repeatability | 25mg – 150mg |

| Eccentricity (tested load) | 1d / 2 mm

|

| Electric compensation range | 0 — 25.5 kg

|

| Stabilization time | 5s |

| Adjustment | internal

|

| Communication interface | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +10 — +40 °C |

| Operating temperature change rate | ±2°C/12h

|

| Relative humidity | 30% — 70%

|

| Relative humidity change rate | ±10%/4h

|

| Weighing pan dimensions | 302×252mm |

| Weighing device dimensions | 370×280×150mm |

| Controling device dimensions | 206×140×70mm |

| Packaging dimensions | 520×520×280mm |

| Net weight | 10.5kg – 11kg |

| Gross weight | 12.7kg – 13.2kg |

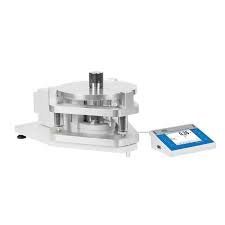

HRP 4Y.KO Mass Comparator

| E1 | –

|

| E2 | –

|

| F1 | –

|

| F2 | 200 kg

|

| M1 | 50 kg — 200 kg/2000 kg

|

| M2 | 10 kg — 200 kg/500 kg — 2000 kg

|

| Maximum capacity [Max] | 210kg – 2100kg |

| Readability [d] | 0.2g – 2g |

| Standard repeatability [5% Max] | 0.4g – 2.5g |

| Standard repeatability [Max] | 0.6g – 5g |

| Permissible repeatability | 1g – 10g |

| Eccentricity (tested load) | 2d / 1 mm

|

| Electric compensation range | 0 — 210 kg

|

| Stabilization time | 10s |

| Adjustment | internal (automatic)

|

| Recommended load speed | 0.3 m/min

|

| Maximum permissible load speed | 0.6 m/min

|

| Communication interface | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±1°C/12h

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ±5%/4h

|

| Weighing pan dimensions | 800×600mm – 1250×1000 mm |

| Self-centering weighing pan dimensions | 600×600mm – 920×920mm |

| Weighing unit dimensions without self-centering weighing pan | 810×600×165mm – 1250×1000×265mm |

| Weighing unit dimensions with self-centering weighing pan | 810×600×260 mm – 1250×1000×265mm |

| Controling device dimensions | 206×140×70 mm |

| Comparator packaging dimensions without self-centering weighing pan | 1000×800×310mm – 1500×1250×635mm |

| Comparator packaging dimensions with self-centering weighing pan | 1000×800×355mm – 1500×1250×635mm |

| Net weight | 105kg – 530kg |

| Net weight | 105kg – 530kg |

| Gross weight | 140kg – 665kg |

| Gross weight | 140kg – 665kg |

HRP 4Y.KB Mass Comparator

The newest line of Radwag Mass Comparators enables adjusting mass standards and weights according to the OIML recommendations (R-111) for M1 class and lower.

The comparators are used both for ensuring traceability of mass measurements, and verification of weights in accordance with legal metrology. RADWAG Mass Comparators have gained recognition among Accredited Calibration Laboratories, in many countries.

HRP 4Y.KO series comparators comprise two components, professional weighing platform (a new mechanical design of electromagnetic mechanism housed within a tight steel casing) and PUE 7.1 terminal.

The weighing platform made of steel features centring rings enabling precise positioning of the weights.

The comparator features intuitive and user friendly menu.

| E1 | –

|

| E2 | –

|

| F1 | –

|

| F2 | –

|

| M1 | 1000 kg

|

| M2 | 200 kg — 1000 kg

|

| Maximum capacity [Max] | 1050 kg |

| Readability [d] | 10 g |

| Standard repeatability [5% Max] | 6 g |

| Standard repeatability [Max] | 10

|

| Permissible repeatability | 15

|

| Eccentricity (tested load) | 1d / 5 mm

|

| Electric compensation range | 0 — 1050 kg

|

| Stabilization time | 10 s |

| Adjustment | internal (automatic)

|

| Recommended load speed | 0.3 m/min

|

| Maximum permissible load speed | 0.6 m/min

|

| Communication interface | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±2°C/12h

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ±10%/4h

|

| Weighing pan dimensions | 1000×800 mm |

| Weighing unit dimensions without self-centering weighing pan | 1010×800×182 mm |

| Controling device dimensions | 206×140×70 mm |

| Comparator packaging dimensions without self-centering weighing pan | 1200×1000×440 mm |

| Net weight | 120 kg |

| Gross weight | 160 kg |

Susceptometer Magnetization

SM-MYA-5.4Y Susceptometer

RADWAG-manufactured susceptometer enables carrying out measurements of magnetic susceptibility and magnetization of weights of E1 and lower classes in accordance with OIML R111.

Modular design, upon disassembling respective module, enables using the susceptometer as a mass comparator or a balance.

Compared to the previous model, the new one features option of internal adjustment and higher readability: [d] 0.1 μg for loads ranging from 2 g to 50 kg.

| E1 | 2 g — 50 kg /2 g — 50 kg

|

| E2 | 2 g — 50 kg / 2 g — 50 kg

|

| F1 | 2 g — 50 kg / 2 g — 50 kg

|

| F2 | 2 g — 50 kg /2 g — 50 kg

|

| Maximum capacity [Max] | 50kg |

| Readability [d] | 1µg |

| Stabilization time | 10s |

| Adjustment | internal (automatic)

|

| Calibration Range | 2g—50kg

|

| Display | 5.7” resistive colour touchscreen

|

| Weighing pan dimensions | ø300mm |

| Device dimensions | 525×350×250mm |

| Packaging dimensions | 950×750×750mm |

| Net weight | 25kg |

| Gross weight | 35kg |

| Dipole moment of magnets | <= 0.1 Am2

|

| Communication interface | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Operating temperature | +15 — +30 °C |

| Operating temperature change rate | ±0.5°C/12h (±0.3°C/4h)

|

| Relative humidity | 40% — 60%

|

| Relative humidity change rate | ± 2 % / 4 h

|

| Housing | ABS plastic

|

| Processor | 2×1 GHz

|

| Memory | RAM 256 MB DDR2, 16GB – karta microSD

|

| Distance platform Z0 | 18; 20; 27; 35; 43 mm |

| Magnetizing field strenght | 2700, 2000, 800, 380, 200 A/m

|