The terminal connects with wireless networks due to a Wireless Connection module, which comes standard.

Data Management

- Products – 15 000

- Operators – 500

- Formulations – 500

- Packaging – 500

- Customers – 500

- Labels – 500

- Universal variables – 100

| Maximum quantity of verification units | 6000 e

|

| OIML Class | III

|

| Maximum quantity of divisions from converter | 838 860 ×10

|

| Maximum increase of signal | 39 mV

|

| Minimum volatge per verification unit | 0.4 µV

|

| Maximum voltage per verification unit | 3.25 µV

|

| Minimum load cell impedance | 50 Ω

|

| Maximum load cell impedance | 1200 Ω

|

| Load cell excitation voltage | 5V DC

|

| Connection of load cells | 4 or 6 wires + shield

|

| Display | LCD (backlit)

|

| Device dimensions | 208×145×80mm |

| Packaging dimensions | 300×250×130mm |

| Net weight | 1.9 kg |

| Gross weight | 2.7kg |

| Protection class | IP 66 / IP 67 / IP 69

|

| Number of buttons | 5

|

| Multiple range | 1 or 2 ranges

|

| Additional LCD display | WD-4/1 (option)

|

| USB Interface | 1

|

| RS232 Interface | 1

|

| Optional interfaces | RS232 or RS485 or 4IN/4OUT or Ethernet or analog output 4-20 mA

|

| Power supply | 100 — 240 V AC 50 / 60 Hz and battery *

|

| Operation time on batteries | max 7h

|

| Operating temperature | -10 — +40 °C |

| Storage temperature | -10 — +50 °C |

| Relative humidity | 10% — 80% RH no condensation

|

| Keypad | microswitch

|

| Housing | stainless steel

|

Functions of an indicator PUE H315 series:

| Maximum quantity of verification units | 6000 e

|

| Maximum quantity of divisions from converter | 838 860 ×10

|

| Maximum increase of signal | 19.2 mV

|

| Minimum volatge per verification unit | 1.0 µV

|

| Maximum voltage per verification unit | 3.2 µV

|

| Minimum load cell impedance | 80 Ω

|

| Maximum load cell impedance | 1200 Ω

|

| Load cell excitation voltage | 5V DC

|

| Connection of load cells | 4 or 6 wires + shield

|

| Display | LCD (backlit)

|

| Device dimensions | 226×250×120mm |

| Packaging dimensions | 300×250×140mm |

| Net weight | 3.5kg |

| Gross weight | 3.8kg |

| Protection class | IP 68 (1h max)/69

|

| Number of buttons | 5

|

| Multiple range | 1 or 2 ranges

|

| Additional LCD display | LCD (option)

|

| Communication interface | RS232

|

| Power supply | 100 — 240 V AC 50 / 60 Hz and battery

|

| Operation time on batteries | 45 h (average time)

|

| Operating temperature | -10 — +40 °C |

| Relative humidity | 10% — 85% RH no condensation

|

| Keypad | microswitch

|

| Housing | stainless steel

|

| Maximum quantity of verification units | 6000 e

|

| OIML Class | III

|

| Maximum quantity of divisions from converter | 838 860 ×10

|

| Maximum increase of signal | 39 mV

|

| Minimum volatge per verification unit | 0.4 µV

|

| Maximum voltage per verification unit | 3.25 µV

|

| Minimum load cell impedance | 50 Ω

|

| Maximum load cell impedance | 1200 Ω

|

| Load cell excitation voltage | 5V DC

|

| Connection of load cells | 4 or 6 wires + shield

|

| Display | LCD (backlit)

|

| Device dimensions | 181×136×60mm |

| Packaging dimensions | 220×190×90mm |

| Net weight | 0.6kg |

| Gross weight | 1.2kg |

| Protection class | IP 43

|

| Power supply | detachable adapter, akumulatory NiMH 6×AA

|

| Number of buttons | 5

|

| Multiple range | 1 or 2 ranges

|

| Additional LCD display | WD-4/8 (option)

|

| RS232 Interface | 1

|

| Optional interfaces | RS232

|

| Power supply | 100 — 240 V AC 50 / 60 Hz

|

| Optional power supply | 12V DC and battery

|

| Operation time on batteries | max 7h

|

| Operating temperature | -10 — +40 °C |

| Storage temperature | -10 — +50 °C |

| Relative humidity | 10% — 80% RH no condensation

|

| Keypad | microswitch

|

| Housing | ABS plastic

|

The terminal connects with wireless networks due to a Wireless Connection module, which comes standard.

Data Management

| Maximum quantity of verification units | 6000 e

|

| Maximum increase of signal | 39 mV

|

| Minimum volatge per verification unit | 0.4 µV

|

| Maximum voltage per verification unit | 3.25 µV

|

| Minimum load cell impedance | 50 Ω

|

| Maximum load cell impedance | 1200 Ω

|

| Load cell excitation voltage | 5V DC

|

| Connection of load cells | 4 or 6 wires + shield

|

| Display | 5” graphic colour

|

| Device dimensions | 206×140×71mm |

| Packaging dimensions | 300×250×130mm |

| Net weight | 0.7kg |

| Gross weight | 1.2kg |

| Protection class | IP 43

|

| Multiple range | YES

|

| Communication interface | 2×RS232, USB-A, USB-B, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Power supply | 100 — 240 V AC 50 / 60 Hz and battery *

|

| Operation time on batteries | operation time up to 5 h

|

| Operating temperature | -10 — +40 °C |

| Housing | ABS plastic

|

| Max number of platforms | 1

|

The PUE 7.1P terminal is a constructional component of industrial load cell scales. It is equipped with 5.7″ TFT display featuring a touch panel and a membrane keypad.

The device offers two proximity sensors which can be programmed using the menu. It can connect with maximum 2 weighing platforms, a barcode scanner, a printer, a labeller, RFID reader and PC equipment (mouse, keyboard, USB flash drive). Standard PUE 7.1P terminal communicates with 1 weighing platform, and is provided with an extended communication interface offering 2×USB, 2×RS 232, Ethernet, 4inputs/4outputs (digital), Wi-Fi®.

It is possible to expand the PUE 7.1 terminal with 1 extra platform, this is done by installation of an additional platform module, DP-6.

Caution: in case of a terminal supporting 2 weighing platforms, only cable version is available (/R version does not exist).

| Maximum quantity of verification units | 6000 e

|

| OIML Class | III

|

| Maximum increase of signal | 19.5 mV

|

| Minimum volatge per verification unit | 0.4 µV

|

| Maximum voltage per verification unit | 3.25 µV

|

| Minimum load cell impedance | 50 Ω

|

| Maximum load cell impedance | 1200 Ω

|

| Load cell excitation voltage | 5V DC

|

| Display | 5.7” resistive colour touchscreen

|

| Device dimensions | 206×140×71mm |

| Packaging dimensions | 300×250×130mm |

| Net weight | 0.8kg |

| Gross weight | 1.2kg |

| Protection class | IP 43

|

| Number of buttons | 8

|

| Database capacity | 16 GB (micro SD)

|

| Communication interface | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (digital), Wi-Fi®

|

| Additional DP6 A/C converter module | 1 (option)

|

| Power consumption max. | max. 1 A

|

| Operating temperature | -10 — +40 °C |

| Relative humidity | 10% — 85% RH no condensation

|

| Keypad | panel touchscreen

|

| Housing | ABS plastic

|

| Operating system | Linux

|

| Processor | quad-core 64-bit Cortex-A53 1.2 GHz

|

| Memory | RAM 1GB LPDDR2

|

| Data memory | 16 GB (micro SD)

|

| Max number of platforms | 2

|

PUE HX5.EX terminal is a constructional component of industrial multifunctional load cell scales. It is the most modern RADWAG solution to be used in areas endangered with explosive atmosphere. The HX5.EX is compliant with ATEX directive regulations. The terminal is intended for operation in environment filled with explosive gases and dust, and can be placed in zones: 1/21 and 2/22.

Standard version of the terminal is equipped with 2 serial intrinsically safe RS232 communication interfaces, and with one intrinsically safe RS485 interface. They facilitate communication with equipment predetermined for use in hazardous areas. Possibility to add digital inputs/outputs expands the range of instruments compatible with the terminal by robotic elements compliant with ATEX directive. For more demanding customers, RADWAG has developed IM01.EX module, installed in the safe area, which extends the available connector range by Ethernet, USB, 4-20mA/0-10V analog outputs, Profibus DP and additional digital inputs/outputs. This enables communication between the terminal and external devices such as barcode scanners, printers, external displays, control buttons, light signalling towers, other controlling/signalling devices, systems for automatic process control and superior IT systems.

Models

There are 4 different models:

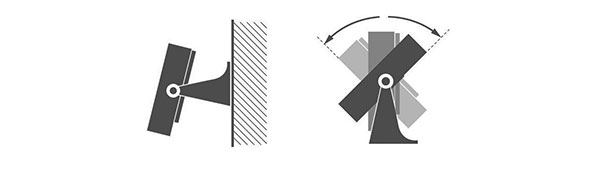

Mechanical Design

The housing, made of AISI 304 stainless steel, ensures high ingress protection, IP66 / IP68 (up to 1.5 m immersion). The terminal features 5″ colour LCD, covered with polycarbonate protecting it against shocks, and a membrane keypad. Ease of operation, clear menu and intuitive information arrangement on the display guarantee comfort of operation. Hermetic intrinsically safe interface connectors are located on the back side of the housing. Stable bracket enables mounting the terminal either on a flat horizontal surface or on the wall. The device tilt can be easily adjusted.

Power Supply

The PUE HX5.EX terminal can be connected to the mains only with a certified intrinsically safe power supply, manufactured by RADWAG:

IM01.EX Communication Module

The terminal’s interface range can be expanded using IM01.EX communication module, connected to the terminal via an intrinsically safe RS485 interface, placed outside the hazardous area.

Models:

Multifunctional Software

Terminal software facilitates processes such as weighing, parts counting, dosing, and percent weighing. Terminal’s information system is based on databases (users, products, weighings, packaging, formulations, customers) and ALIBI memory which guarantees stored data safety. The interfaces enable communication between the terminal and the accessories intended for operation in the hazardous and non-hazardous areas. Accessories: barcode scanners, printers, external displays, control buttons, light signalling towers and other controlling/signalling devices. The terminal can communicate with systems for automatic process control and superior IT systems.

| Maximum quantity of verification units | 6000 e

|

| OIML Class | III

|

| Maximum quantity of divisions from converter | 100 000

|

| Maximum increase of signal | 19.5 mV

|

| Minimum volatge per verification unit | 0.4 µV

|

| Minimum load cell impedance | 80 Ω

|

| Maximum load cell impedance | 1200 Ω

|

| Connection of load cells | 4 or 6 wires + shield

|

| Display | 5” graphic colour

|

| Device dimensions | 329×231×120mm |

| Packaging dimensions | 640×310×220mm |

| Net weight | 7.8kg |

| Gross weight | 8.8kg |

| Protection class | IP 66 / IP 68

|

| ATEX Certification | II 2G Ex ib IIC T4 Gb (gases)

|

| Working in zones | 1, 2 (gases); 21, 22 (dusts)

|

| Communication interface | 2×RS232, RS485

|

| Operating temperature | -10 — +40 °C |

| Housing | stainless steel

|