Ovens and Forced Convection Furnaces up to 850 °C

Ovens and Forced Convection Furnaces up to 850 °C

Ovens electrically heated

With their maximum working temperature of up to 300 °C and forced air circulation, the ovens achieve a very good temperature uniformity. They can be used for various applications such as e.g. drying, sterilizing or warm storing. Short delivery times from stock are ensured for standard models.

- Tmax 300 °C

- Working temperature range: + 20 °C above room temperature up to 300 °C

- Ovens TR 30 – TR 420 designed as tabletop models

- Ovens TR 450 – TR 1050 designed as floor standing models

- Horizontal forced air circulation results in temperature uniformity according to DIN 17052-1 better than +/− 5 °C in the empty work space (with closed exhaust air flap)

- Stainless steel furnace housing, material no. 1.4016 (DIN)

- Stainless steel chamber, alloy 304 (AISI)/(DIN material no. 1.4301), rust-resistant and easy to clean

- Charging in multiple layers possible using removeable grids (number of removeable grids included, see table to the right)

- Large, wide-opening swing door, hinged on the right with quick release for models TR 30 – TR 240 and TR 450

- Double swing door with quick release for models TR 420, TR 800 and TR 1050

- Ovens TR 800 and TR 1050 equipped with transport castors

- Infinitely adjustable exhaust at the rear wall with operation from the front

- PID microprocessor control with self-diagnosis system

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- Controller R7

- Solid state relays provide for lownoise operation

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documention of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the oven and load

- Fan speed of the air circulation fan can be reduced infinitely

- Window for charge observing

- Further removeable grids with rails

- Side inlet

- Electrical rotary device (associated sample holder will be individually adapted to the charge)

- Exhaust air duct DN 80

- Transport castors for models TR 240 – TR 450

- Upgrading available to meet the quality requirements of AMS2750F or FDA

- Process control and documentation via VCD software package for monitoring, documentation and control

- Fresh-air filter to reduce dust inside the furnace

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | Minutes | Grids | Grids | Max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | w | d | h | in l | W | D | H | load in kW | connection | in kg | to Tmax2 | included | max. | total load3 | |

| TR 30 | 300 | 360 | 300 | 300 | 30 | 610 | 570 | 665 | 2.1 | 1-phase | 45 | 25 | 1 | 4 | 80 |

| TR 60 | 300 | 450 | 390 | 350 | 60 | 700 | 610 | 710 | 3.1 | 1-phase | 90 | 25 | 1 | 4 | 120 |

| TR 120 | 300 | 650 | 390 | 500 | 120 | 900 | 610 | 860 | 3.1 | 1-phase | 120 | 45 | 2 | 7 | 150 |

| TR 240 | 300 | 750 | 550 | 600 | 240 | 1000 | 780 | 970 | 3.1 | 1-phase | 165 | 60 | 2 | 8 | 150 |

| TR 420 | 300 | 1300 | 550 | 600 | 420 | 1550 | 815 | 970 | 6.3 | 3-phase | 250 | 60 | 2 | 8 | 200 |

| TR 450 | 300 | 750 | 550 | 1100 | 450 | 1000 | 780 | 1470 | 6.3 | 3-phase | 235 | 60 | 3 | 15 | 180 |

| TR 800 | 300 | 1200 | 670 | 1000 | 800 | 1470 | 970 | 1520 | 6.3 | 3-phase | 360 | 80 | 3 | 10 | 250 |

| TR 1050 | 300 | 1200 | 670 | 1400 | 1050 | 1470 | 970 | 1920 | 9.3 | 3-phase | 450 | 80 | 4 | 14 | 250 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2In the empty and closed oven, connected to 230 V 1/N/PE resp. 400 V 3/N/PE 3Max load per layer 30 kg | |||||||||||||||

Ovens with Safety Technology

Ovens in the TR .. LS range with safety equipment based on EN 1539 Type A are suitable for drying charges containing solvents. With their compact design, these ovens can be easily integrated into a laboratory or production process. Exhaust gases escape through an outlet on the back of the oven and can then be extracted or treated.

- Furnace technology based on ovens

- For a description of the safety technology refer to models NA 120/45 LS ff.

- Tmax 260 °C

- Temperature uniformity ±8 K according to DIN 17052-1 in empty work space

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- Controller with touch operation B510 (5 programs with 4 segments each)

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documention of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Fan speed of the air circulation fan can be reduced infinitely

- Window for charge observing

- Further removeable grids with rails

- Side inlet

- Electrical rotary device (associated sample holder will be individually adapted to the charge)

- Exhaust air duct DN 80

- Transport castors for models TR 240 – TR 450

- Upgrading available to meet the quality requirements of AMS2750F or FDA

- Fresh-air filter to reduce dust inside the furnace

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions3 in mm | Connected load | Electrical | Weight | Minutes | Grids | Grids | Total load | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H | kW2 | connection | in kg | to Tmax4 | incl. | max. | max.1 | |

| TR 60 LS | 260 | 450 | 380 | 350 | 60 | 700 | 820 | 710 | 5.3 | 3-phase | 100 | 20 | 1 | 4 | 96 |

| TR 120 LS | 260 | 650 | 380 | 500 | 120 | 900 | 820 | 870 | 6.3 | 3-phase | 120 | 22 | 2 | 7 | 140 |

| TR 240 LS | 260 | 750 | 540 | 600 | 240 | 1000 | 990 | 970 | 6.3 | 3-phase | 180 | 32 | 2 | 8 | 170 |

| TR 450 LS | 260 | 750 | 540 | 1100 | 450 | 1000 | 990 | 1470 | 12.6 | 3-phase | 250 | 36 | 3 | 15 | 250 |

| 1Maximum load per level 30 kg 2Connected load is higher with EN 1539 as additional equipment 3External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 4In empty, closed furnace when connected to 230 V 1/N/PE or 400 V 3/N/PE | |||||||||||||||

Chamber Ovens up to 260 °C

The chamber ovens of the KTR range can be used for complex drying processes and heat treatment of charges to an application temperature of 260 °C. The high-performance air circulation enables optimum temperature uniformity throughout the work space. A wide range of accessories allow the chamber ovens to be modified to meet specific process requirements.

Standard Equipment

- Tmax 260 °C

- Electrically heated (via a heating register with integrated chrome steel heating elements) or gas-fired (direct or indirect gas-fired including injection of the hot air into the intake duct)

- Temperature uniformity up to +/− 3 °C according to DIN 17052-1 (for design wihout track cutouts)

- High-quality mineral wool insulation provides for outer temperatures of < 25 °C above room temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- High air exchange for fast drying processes

- Double-wing door for furnaces KTR 2300 and larger

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Controller B400 (5 prgrams with each 4 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Base frame to charge the oven via a charging forklift

- Additional Door in the back for charging from both sides or to use the oven as lock between two rooms

- Fan system for faster cooling with manual or motorized control of the exhaust flaps

- Programmed opening and closing of exhaust air flaps

- Air circulation with speed control, recommendable for processes with light or sensitive charge

- Observation window and furnace chamber lighting

- All KTR-models are also available with Tmax 300 °C

- Process control and documentation via VCD software package or Nabertherm Control Center (NCC) for monitoring, documentation and control

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Heating power | Electrical | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H | in kW1 | connection* | |

| KTR 1000 | 260 | 1000 | 1000 | 1000 | 1000 | 1820 | 1430 | 1890 | 18 | 3-phase |

| KTR 1500 | 260 | 1000 | 1000 | 1500 | 1500 | 1820 | 1430 | 2390 | 18 | 3-phase |

| KTR 2000 | 260 | 1100 | 1500 | 1200 | 2000 | 1920 | 1930 | 2090 | 18 | 3-phase |

| KTR 2300 | 260 | 1250 | 1250 | 1500 | 2300 | 2120 | 1680 | 2460 | 27 | 3-phase |

| KTR 3100 | 260 | 1250 | 1250 | 2000 | 3100 | 2120 | 1680 | 2960 | 27 | 3-phase |

| KTR 3400 | 260 | 1500 | 1500 | 1500 | 3400 | 2370 | 1930 | 2460 | 45 | 3-phase |

| KTR 4500 | 260 | 1500 | 1500 | 2000 | 4500 | 2370 | 1930 | 2960 | 45 | 3-phase |

| KTR 4600 | 260 | 1750 | 1750 | 1500 | 4600 | 2620 | 2175 | 2480 | 45 | 3-phase |

| KTR 6000 | 260 | 2000 | 2000 | 1500 | 6000 | 2870 | 2430 | 2460 | 54 | 3-phase |

| KTR 6125 | 260 | 1750 | 1750 | 2000 | 6125 | 2620 | 2175 | 2980 | 45 | 3-phase |

| KTR 6250 | 260 | 1250 | 2500 | 2000 | 6250 | 2120 | 3035 | 2960 | 54 | 3-phase |

| KTR 8000 | 260 | 2000 | 2000 | 2000 | 8000 | 2870 | 2430 | 2960 | 54 | 3-phase |

| KTR 9000 | 260 | 1500 | 3000 | 2000 | 9000 | 2490 | 3870 | 2920 | 72 | 3-phase |

| KTR 12300 | 260 | 1750 | 3500 | 2000 | 12300 | 2620 | 4350 | 2980 | 90 | 3-phase |

| KTR 13250 | 260 | 1250 | 5000 | 2000 | 13250 | 2120 | 6170 | 2960 | 108 | 3-phase |

| KTR 16000 | 260 | 2000 | 4000 | 2000 | 16000 | 2870 | 4850 | 2960 | 108 | 3-phase |

| KTR 21300 | 260 | 2650 | 3550 | 2300 | 21300 | 3600 | 4195 | 3380 | 108 | 3-phase |

| KTR 22500 | 260 | 2000 | 4500 | 2500 | 22500 | 3140 | 5400 | 3500 | 108 | 3-phase |

| 1Depending on furnace design connected load might be higher*Please see page 75 for more information about supply voltage 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request | ||||||||||

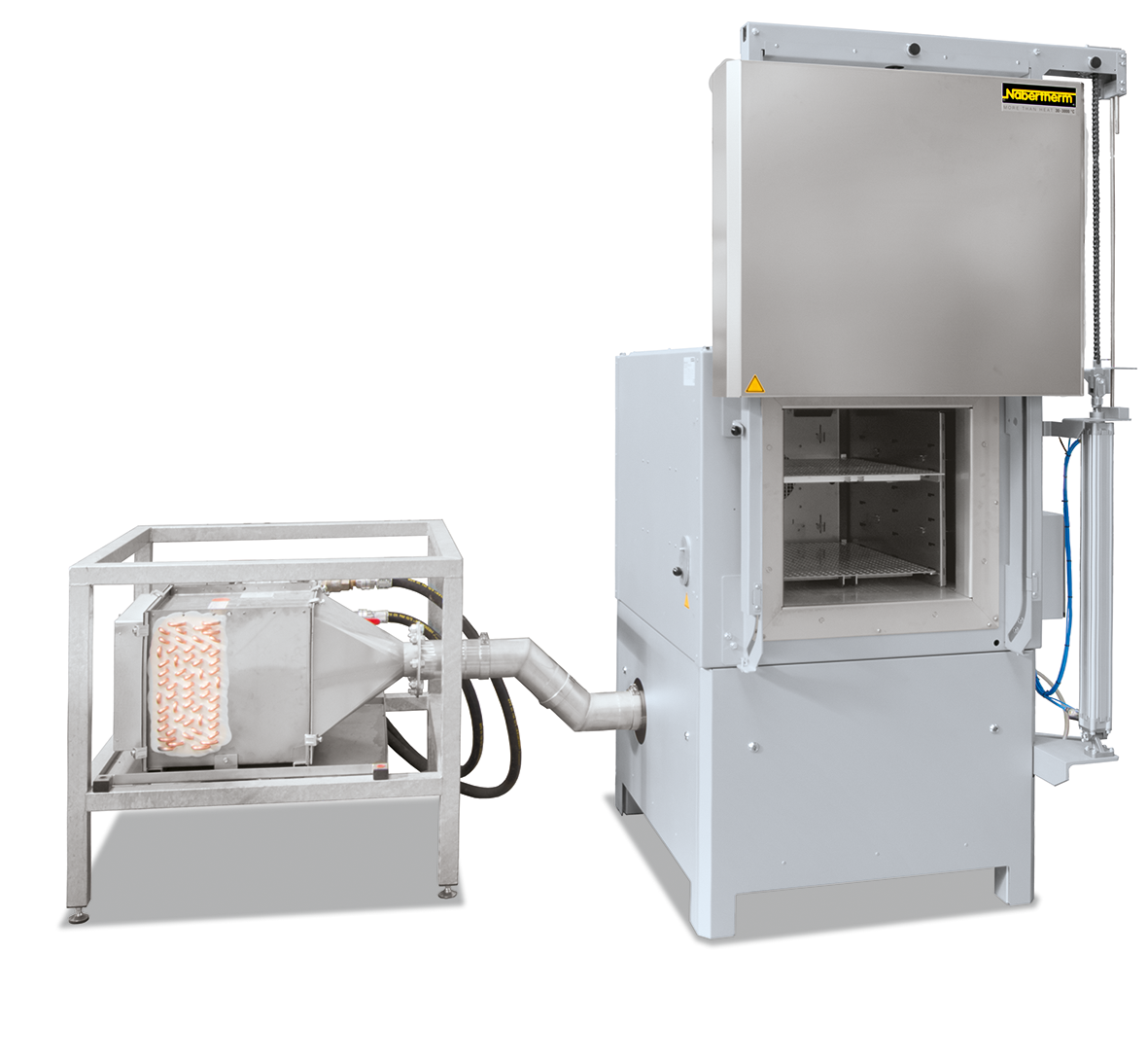

Forced Convection Chamber Furnaces up to 675 Liter electrically heated

The very good temperature uniformity of these chamber furnace with air circulation provides for ideal process conditiones for annealing, curing, solution annealing, artificial ageing, sintering of PTFE, preheating, or soft annealing and brazing. The forced convection chamber furnaces are equipped with a suitable annealing box for soft annealing of copper or tempering of titanium, and also for annealing of steel under non-flammable protective or reaction gases. The modular forced convection chamber furnace design allows for adaptation to specific process requirements with appropriate accessories.

- Tmax 450 °C, 650 °C, or 850 °C

- Horizontal air circulation with optimum distribution through stainless steel baffles

- Swing door hinged on the right side

- Base frame included in the delivery

- Temperature uniformity up to +/− 4 °C according to DIN 17052-1

- Optimum air distribution enabled by high flow speeds

- One frame sheet and rails for two additional trays included in the scope of delivery

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- Controller with touch operation B500 (5 programs with 4 segments each)

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documention of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

Additional Equipment for Models up to 450 °C

- Air inlet and exhaust air flaps when used for drying

- Controlled cooling via controlled flap and fan

- Additional frame sheet

- Gas supply boxes for different charging methods

- Gas feed fittings

- Charge control with documentation of the charge thermocouple

- Signal tower

- Charging systems

- Process control and documentation via VCD software package for monitoring, documentation and control

Further Additional Equipment for Models up to 850 °C

- Optimization of the temperature uniformity up to +/− 3 °C according to DIN 17052-1

- Measuring frames and thermocouples for TUS measurements charge or comparative measurements

- Version according to AMS2750F or CQI-9

- Manual lift door (up to model NA 120/..)

- Pneumatic lift door

- Manual roller conveyor in furnace chamber for high charge weights

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating | Electrical | Weight | Heat-up time3 | Cool-down time3 from Tmax | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| power | to Tmax | to 150 °C in minutes | ||||||||||||

| °C | w | d | h | in l | W | D | H | in kW2 | connection | in kg | in minutes | Flaps4 | Fan cooling4 | |

| NA 120/45 | 450 | 450 | 600 | 450 | 120 | 1250 | 1550 | 1550 | 9.0 | 3-phase | 460 | 60 | 240 | 30 |

| NA 250/45 | 450 | 600 | 750 | 600 | 250 | 1350 | 1650 | 1725 | 12.0 | 3-phase | 590 | 60 | 120 | 30 |

| NA 500/45 | 450 | 750 | 1000 | 750 | 500 | 1550 | 1900 | 1820 | 18.0 | 3-phase | 750 | 60 | 240 | 30 |

| NA 60/65 | 650 | 350 | 500 | 350 | 60 | 910 | 1390 | 1475 | 9.0 | 3-phase | 350 | 120 | 270 | 60 |

| NA 120/65 | 650 | 450 | 600 | 450 | 120 | 990 | 1470 | 1550 | 12.0 | 3-phase | 460 | 60 | 300 | 60 |

| NA 250/65 | 650 | 600 | 750 | 600 | 250 | 1170 | 1650 | 1680 | 20.0 | 3-phase | 590 | 90 | 270 | 60 |

| NA 500/65 | 650 | 750 | 1000 | 750 | 500 | 1290 | 1890 | 1825 | 27.0 | 3-phase | 750 | 60 | 240 | 60 |

| NA 60/85 | 850 | 350 | 500 | 350 | 60 | 790 | 1330 | 1440 | 9.0 | 3-phase | 315 | 150 | 900 | 120 |

| NA 120/85 | 850 | 450 | 600 | 450 | 120 | 890 | 1420 | 1540 | 12.0 | 3-phase | 390 | 150 | 900 | 120 |

| NA 250/85 | 850 | 600 | 750 | 600 | 250 | 1120 | 1690 | 1810 | 20.0 | 3-phase | 840 | 180 | 900 | 180 |

| NA 500/85 | 850 | 750 | 1000 | 750 | 500 | 1270 | 1940 | 1960 | 30.0 | 3-phase | 1150 | 180 | 900 | 210 |

| NA 675/85 | 850 | 750 | 1200 | 750 | 675 | 1270 | 2190 | 1960 | 30.0 | 3-phase | 1350 | 210 | 900 | 210 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Depending on furnace design connected load might be higher 3Approx. information in empty furnace 4Additional equipment | ||||||||||||||

Forced Convection Chamber Furnaces – Tabletop Design electrically heated

These forced convection chamber furnaces are characterized by their extremely high temperature uniformity. Due to the compact tabletop design, this series is very well suited for installation in laboratories or rooms with limited space.

Applications include preheating of components for shrink-fit processes, heat treatment of metals in air such as aging, stress relieving, soft annealing or tempering, and heat treatment of glass.

- Tmax 650 °C or 850 °C

- Horizontal air circulation with optimum distribution through stainless steel baffles

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Integrated control unit

- Swing door hinged on the right side, door opening temperatures up to 400 °C

- Temperature uniformity up to +/− 6 °C according to DIN 17052-1 (model NAT 15/65 up to +/− 5 °C)

- Optimum air distribution enabled by high flow speeds

- Air inlet in the rear wall of the furnace

- Adjustable exhaust port in the furnace ceiling (not for model NAT 15/65)

- 15 mm port in the furnace ceiling (not for model NAT 15/65)

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- Controller with touch operation B500/B510 (5 programs with 4 segments each)

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documention of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

Additional equipment (not for NAT 15/65)

- Base frame

- Charging racks for loading on several levels

- Equipment package with batch control and process control and documentation via VCD software package

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating | Electrical | Weight | Heat-up time3 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| power | to Tmax | |||||||||||

| °C | w | d | h | in l | W | D | H | in kW2 | connection | in kg | in minutes | |

| NAT 15/65 | 650 | 295 | 340 | 170 | 15 | 470 | 790 | 460 | 2,8 | 1-phase | 60 | 40 |

| NAT 30/65 | 650 | 320 | 320 | 300 | 30 | 810 | 620 | 620 | 3,0 | 1-phase | 90 | 80 |

| NAT 60/65 | 650 | 400 | 400 | 400 | 60 | 890 | 700 | 720 | 3,0 | 1-phase | 110 | 100 |

| NAT 15/85 | 850 | 320 | 320 | 150 | 15 | 690 | 880 | 570 | 3,0 | 1-phase | 85 | 190 |

| NAT 30/85 | 850 | 320 | 320 | 300 | 30 | 690 | 880 | 720 | 3,0 | 1-phase | 100 | 230 |

| NAT 50/85 | 850 | 400 | 320 | 400 | 50 | 770 | 880 | 820 | 4,5 | 3-phase | 130 | 230 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Depending on furnace design connected load might be higher 3Approx. information in empty furnace | ||||||||||||