High-Temperature Furnaces up to 1800 °C

High-Temperature Furnaces up to 1800 °C

High-Temperature Furnaces with SiC Rod Heating up to 1600 °C

These powerful laboratory muffle furnaces are available for temperatures up to 1550 °C or 1600 °C. The durability of the SiC rods in periodic use, in combination with their high heating speed, make these high-temperature furnaces to all-rounders in the laboratory. Heating times of 25 – 30 minutes can be achieved, depending on the furnace model and the conditions of use.

Standard Equipment

- Tmax 1550 °C or 1600 °C

- Working temperature 1500 °C, increased wear and tear must be expected in case of working at higher temperatures

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Optional flap door (LHTC) which can be used as work platform or lift door (LHTCT) with hot surface facing away from the operator (High-temperature furnace LHTCT 01/16 only with lift door)

- Switching system with solid-state-relays, power tuned to the SiC rods

- Easy replacement of heating rods

- Adjustable air inlet opening, exhaust air opening in the roof

- Controller C550 (10 programs with each 20 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Protective gas connection to purge with non-flammable protective or reaction gases, not gas tight

- Manual or automatic gas supply system

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | Heating time | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | w | d | h | in l | W | D | H2 | load in kW | connection* | in kg | in min3 | |

| LHTCT 01/16 | 1550 | 110 | 120 | 120 | 1.5 | 340 | 300 | 460 | 3.5 | 1-phase | 18 | 30 |

| LHTC(T) 03/16 | 1600 | 120 | 210 | 120 | 3.0 | 415 | 545 | 490 | 10.0 | 3-phase4 | 30 | 30 |

| LHTC(T) 08/16 | 1600 | 170 | 290 | 170 | 8.0 | 490 | 625 | 540 | 15.5 | 3-phase | 40 | 25 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request.*Please see page 75 for more information about supply voltage 2Plus maximum 240 mm for models LHTCT when open4Heating only between two phases | ||||||||||||

High-Temperature Furnaces with MoSi₂ Heating Elements up to 1800 °C

Designed as tabletop models, these compact high-temperature furnaces have a variety of advantages. The first-class workmanship using high-quality materials, combined with ease of operation, make these furnaces all-rounders in research and the laboratory. These high-temperature furnaces are also perfectly suited for the sintering of technical ceramics, such as zirconium oxide dental bridges.

Standard Equipment

- Tmax 1600 °C, 1750 °C, or 1800 °C

- Recommended working temperature 1750 °C (for models LHT ../18), increased wear and tear must be expected in case of working at higher temperatures

- High-quality molybdenum disilicide heating elements

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Adjustable air inlet opening, exhaust air opening in the roof

- Type B thermocouple

- Controller P470 (50 programs with each 40 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Protective gas connection to purge with non-flammable protective or reaction gases, not gas tight

- Manual or automatic gas supply system

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | Heating time | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | w | d | h | in l | W | D | H2 | load in kW | connection* | in kg | in min3 | |

| LHT 02/16 | 1600 | 90 | 150 | 150 | 2 | 470 | 630 | 760+260 | 3.0 | 1-phase | 75 | 30 |

| LHT 04/16 | 1600 | 150 | 150 | 150 | 4 | 470 | 630 | 760+260 | 5.2 | 3-phase4 | 85 | 25 |

| LHT 08/16 | 1600 | 150 | 300 | 150 | 8 | 470 | 810 | 760+260 | 8.0 | 3-phase4 | 100 | 25 |

| LHT 01/17 D | 1650 | 110 | 120 | 120 | 1 | 385 | 425 | 525+195 | 2.9 | 1-phase | 28 | 35 |

| LHT 03/17 D | 1650 | 135 | 155 | 200 | 4 | 470 | 630 | 760+260 | 3.0 | 1-phase | 75 | 30 |

| LHT 02/17 | 1750 | 90 | 150 | 150 | 2 | 470 | 630 | 760+260 | 3.0 | 1-phase | 75 | 35 |

| LHT 04/17 | 1750 | 150 | 150 | 150 | 4 | 470 | 630 | 760+260 | 5.2 | 3-phase4 | 85 | 30 |

| LHT 08/17 | 1750 | 150 | 300 | 150 | 8 | 470 | 810 | 760+260 | 8.0 | 3-phase4 | 100 | 30 |

| LHT 02/18 | 1800 | 90 | 150 | 150 | 2 | 470 | 630 | 760+260 | 3.6 | 1-phase | 75 | 60 |

| LHT 04/18 | 1800 | 150 | 150 | 150 | 4 | 470 | 630 | 760+260 | 5.2 | 3-phase4 | 85 | 40 |

| LHT 08/18 | 1800 | 150 | 300 | 150 | 8 | 470 | 810 | 760+260 | 9.0 | 3-phase4 | 100 | 40 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request.*Please see page 75 for more information about supply voltage 2Including opened lift door4Heating only between two phases 3Heating time of the empty and closed furnace up to Tmax −100 K (connected to 230 V 1/N/PE rsp. 400 V 3/N/PE) | ||||||||||||

High-Temperature Bottom Loading Furnaces up to 1650 °C

The motorized lifting table significantly simplifies the charging of the high-temperature furnaces LHT ../.. LB (Speed). The heating all around the cylindrical furnace chamber provides for an optimal temperature uniformity. For the tabletop models LHT 01/17 LB Speed and LHT 02/17 LB Speed the charge can be placed in charge saggars made of technical ceramics. Up to three charge saggars can be stacked on top of each other resulting in a high productivity.

Standard Equipment

- Tmax 1650 °C

- High-quality heating elements made of molybdenum disilicide offer very good protection against chemical interaction between charge and heating elements

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Excellent temperature uniformity thanks to three (LHT 02/17 LB Speed) or four-sided (LHT 01/17 LB Speed) heating of the furnace chamber

- Furnace chamber with a volume of 1 or 2 liters, table with large floor space

- Precise, motorized toothed belt drive of the table with button operation

- Exhaust air vent in the roof

- Type S thermocouple

- Controller P580 (50 programs with each 40 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Stackable saggars for loading in up to two or three levels, depending on model

- Adjustable air inlet through the floor

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax | Work space dimensions2 in mm | Charging area in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | w | d | h | w | d | in l | W | D | H | load in kW | connection | in kg | |

| LHT 01/17 LB Speed | 1650 | 75 | 110 | 60 | 95 | 130 | 1 | 350 | 590 | 695 | 2.9 | 1-phase | 45 |

| LHT 02/17 LB Speed | 1650 | Ø 115 | 140 | 135 | 135 | 2 | 390 | 590 | 785 | 3.3 | 1-phase | 55 | |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Corresponds to charge saggars with spacer | |||||||||||||

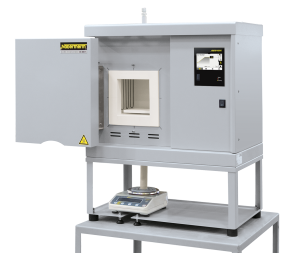

High-Temperature Furnaces with Scale for Determination of Combustion Loss and Thermogravimetric Analysis (TGA) up to 1750 °C

These high-temperature furnaces were specially developed to determine combustion loss during annealing and for thermogravimetric analysis (TGA) in the lab. The complete system consists of the high-temperature furnace for 1600 °C or 1750 °C, a table frame, precision scale with feedthroughs into the furnace and powerful software for recording both the temperature curve and the weight loss over time.

Standard Equipment

- Defined application within the constraints of the operating instructions

- Tmax 1600 °C or 1750 °C

- High-quality molybdenum disilicide heating elements

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Adjustable air inlet

- Exhaust air opening in the roof

- Type B thermocouple

- Delivery includes base, ceramic plunger with base plate in the furnace lining, precision scale and software package

- 4 scales available for different maximum weights and scaling ranges

- Process control and documentation for temperature and combustion loss via VCD software package for monitoring, documentation and control

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | Heating time | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | w | d | h | in l | W | D | H | load in kW | connection* | in kg | in min2 | |

| LHT 04/16 SW | 1600 | 150 | 150 | 150 | 4 | 655 | 370 | 890 | 5.0 | 3-phase3 | 85 | 25 |

| LHT 04/17 SW | 1750 | 150 | 150 | 150 | 4 | 655 | 370 | 890 | 5.0 | 3-phase3 | 85 | 30 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request.*Please see page 75 for more information about supply voltage 2Heating time of the empty and closed furnace up to Tmax −100 K (connected to 230 V 1/N/PE rsp. 400 V 3/N/PE) 3Heating only between two phases | ||||||||||||

| Scale | Readability | Maximum weighing range | Weight of plunger | Calibration value | Minimum load |

|---|---|---|---|---|---|

| type | in g | in g | in g | in g | in g |

| EW-2200 | 0.01 | 2200 incl. plunger | 850 | 0.1 | 0.5 |

| EW-4200 | 0.01 | 4200 incl. plunger | 850 | 0.1 | 0.5 |

| EW-6200 | 0.01 | 6200 incl. plunger | 850 | – | 1.0 |

| EW-12000 | 0.10 | 12000 incl. plunger | 850 | 1.0 | 5.0 |

High-Temperature Furnaces with Molybdenum Disilicide Heating Elements with Fiber Insulation up to 1800 °C

Due to their solid construction and compact stand-alone design, these high-temperature furnaces are perfect for processes in the laboratory where the highest precision is needed. Oustanding temperature uniformity and practical details set unbeatable quality benchmarks. For configuration for your processes, these furnaces can be extended with extras from our extensive option list.

- Tmax 1600 °C, 1750 °C, or 1800 °C

- Recommended working temperature 1750 °C (for models HT ../18), increased wear and tear must be expected in case of working at higher temperatures

- Dual shell housing with fan cooling for low shell temperatures

- Heating from both sides via molybdenum disilicide heating elements

- High-quality fiber insulation backed by special insulation

- Side insulation constructed with tongue and groove blocks provides for low heat loss to the outside

- Long-life roof insulation with special suspension

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Chain-guided parallel swivel door for defined opening and closing of the door

- Two-door design (front/back) for high-temperature furnaces > HT 276/..

- Labyrinth sealing ensures the least possible temperature loss in the door area

- Reinforced floor as protection for bottom insulation as standard from models HT 16/16 upwards

- Vapor vent in the furnace roof with motorized exhaust air flaps

- Heating elements switched via thyristors

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Uncontrolled or controlled cooling system with frequency-controlled cooling fan and motorized exhaust air flap

- Furnace in DB design featuring fresh air preheating, exhaust gas ventilation and an extensive safety package for debinding and sintering in one process, i. e. without transfering the material from the debinding furnace to the sintering furnace

- Stainless steel exhaust hood as interface to customer’s exhaust system for all standing models

- Special heating elements for zirconia sintering provide for longer service life with respect to chemical interaction between charge and heating elements

- Protective gas connection to purge with non-flammable protective or reaction gases

- Manual or automatic gas supply system

- Inner process box to improve the gas tightness and to protect the furnace chamber against contamination

- Lift door

- Motorized exhaust air flap, switchable via the program

- Thermal or catalytic exhaust cleaning systems

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H | load kW | connection | in kg | |

| HT 08/16 | 1600 | 150 | 300 | 150 | 8 | 740 | 640 | 1755 | 8.5 | 3-phase2 | 215 |

| HT 16/16 | 1600 | 200 | 300 | 260 | 16 | 820 | 690 | 1860 | 12.5 | 3-phase2 | 300 |

| HT 29/16 | 1600 | 275 | 300 | 350 | 29 | 985 | 740 | 1990 | 9.8 | 3-phase2 | 350 |

| HT 40/16 | 1600 | 300 | 350 | 350 | 40 | 1010 | 800 | 1990 | 12.5 | 3-phase | 420 |

| HT 64/16 | 1600 | 400 | 400 | 400 | 64 | 1140 | 890 | 2040 | 18.5 | 3-phase | 555 |

| HT 128/16 | 1600 | 400 | 800 | 400 | 128 | 1140 | 1280 | 2040 | 26.5 | 3-phase | 820 |

| HT 160/16 | 1600 | 500 | 550 | 550 | 160 | 1250 | 1040 | 2260 | 21.5 | 3-phase | 760 |

| HT 276/16 | 1600 | 500 | 1000 | 550 | 276 | 1340 | 1600 | 2290 | 36.5 | 3-phase | 1270 |

| HT 450/16 | 1600 | 500 | 1150 | 780 | 450 | 1360 | 1820 | 2570 | 65.0 | 3-phase | 1570 |

| HT 08/17 | 1750 | 150 | 300 | 150 | 8 | 740 | 640 | 1755 | 8.5 | 3-phase2 | 215 |

| HT 16/17 | 1750 | 200 | 300 | 260 | 16 | 820 | 690 | 1860 | 12.5 | 3-phase2 | 300 |

| HT 29/17 | 1750 | 275 | 300 | 350 | 29 | 985 | 740 | 1990 | 9.8 | 3-phase2 | 350 |

| HT 40/17 | 1750 | 300 | 350 | 350 | 40 | 1010 | 800 | 1990 | 12.5 | 3-phase | 420 |

| HT 64/17 | 1750 | 400 | 400 | 400 | 64 | 1140 | 890 | 2040 | 18.5 | 3-phase | 555 |

| HT 128/17 | 1750 | 400 | 800 | 400 | 128 | 1140 | 1280 | 2040 | 26.5 | 3-phase | 820 |

| HT 160/17 | 1750 | 500 | 550 | 550 | 160 | 1250 | 1040 | 2260 | 21.5 | 3-phase | 760 |

| HT 276/17 | 1750 | 500 | 1000 | 550 | 276 | 1340 | 1600 | 2290 | 36.5 | 3-phase | 1270 |

| HT 450/17 | 1750 | 500 | 1150 | 780 | 450 | 1360 | 1820 | 2570 | 65.0 | 3-phase | 1570 |

| HT 08/18 | 1800 | 150 | 300 | 150 | 8 | 740 | 640 | 1755 | 8.5 | 3-phase2 | 215 |

| HT 16/18 | 1800 | 200 | 300 | 260 | 16 | 820 | 690 | 1860 | 12.5 | 3-phase2 | 300 |

| HT 29/18 | 1800 | 275 | 300 | 350 | 29 | 985 | 740 | 1990 | 9.8 | 3-phase2 | 350 |

| HT 40/18 | 1800 | 300 | 350 | 350 | 40 | 1010 | 800 | 1990 | 12.5 | 3-phase | 420 |

| HT 64/18 | 1800 | 400 | 400 | 400 | 64 | 1140 | 890 | 2040 | 18.5 | 3-phase | 555 |

| HT 128/18 | 1800 | 400 | 800 | 400 | 128 | 1140 | 1280 | 2040 | 26.5 | 3-phase | 820 |

| HT 160/18 | 1800 | 500 | 550 | 550 | 160 | 1250 | 1040 | 2260 | 21.5 | 3-phase | 760 |

| HT 276/18 | 1800 | 500 | 1000 | 550 | 276 | 1340 | 1600 | 2290 | 36.5 | 3-phase | 1270 |

| HT 450/18 | 1800 | 500 | 1150 | 780 | 450 | 1360 | 1820 | 2570 | 65.0 | 3-phase | 1570 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Heating only between two phases | |||||||||||

High-Temperature Furnaces with SiC Rod Heating up to 1550 °C

The high-temperature furnaces HTC 16/16 – HTC 450/16 are heated by vertically hung SiC rods, which makes them especially suitable for sintering processes up to a maximum operating temperature of 1550 °C. For some processes, e.g. for sintering zirconia, the absence of interactivity between the charge and the SiC rods, these models are more suitable than the alternatives heated with molybdenum disilicide elements. The basic construction of these furnaces make them comparable with the already familiar models in the HT product line and they can be upgraded with the same additional equipment.

- Tmax 1550 °C

- Dual shell housing with fan cooling for low shell temperatures

- Heating from both sides via vertically mounted SiC rods

- High-quality fiber insulation backed by special insulation

- Side insulation constructed with tongue and groove blocks provides for low heat loss to the outside

- Long-life roof insulation with special suspension

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Chain-guided parallel swivel door for defined opening and closing of the door without destroying the insulation

- Two-door design (front/back) for high-temperature furnaces > HTC 276/..

- Labyrinth sealing ensures the least possible temperature loss in the door area

- Reinforced floor as protection for fiber insulation and to load heavy weights

- Vapor vent in the furnace roof with motorized exhaust air flaps

- Heating elements switched via SCR‘s

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Like HT models

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating Power | Connected | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in°C | w | d | h | in l | W | D | H | in kW | load in kW | connection | in kg | |

| HTC 16/16 | 1550 | 200 | 300 | 260 | 16 | 820 | 690 | 1860 | 12.0 | 16,5 | 3-phase2 | 220 |

| HTC 40/16 | 1550 | 300 | 350 | 350 | 40 | 1010 | 800 | 1990 | 12.0 | 16,5 | 3-phase | 420 |

| HTC 64/16 | 1550 | 400 | 400 | 400 | 64 | 1140 | 890 | 2040 | 18.0 | 41,5 | 3-phase | 660 |

| HTC 128/16 | 1550 | 400 | 800 | 400 | 128 | 1140 | 1280 | 2040 | 26.0 | 61,0 | 3-phase | 550 |

| HTC 160/16 | 1550 | 500 | 550 | 550 | 160 | 1250 | 1040 | 2260 | 21.0 | 40,0 | 3-phase | 535 |

| HTC 276/16 | 1550 | 500 | 1000 | 550 | 276 | 1340 | 1600 | 2290 | 36.0 | 73,0 | 3-phase | 1300 |

| HTC 450/16 | 1550 | 500 | 1150 | 780 | 450 | 1360 | 1800 | 2570 | 64.0 | 118,0 | 3-phase | 1450 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Heating only between two phases | ||||||||||||

High Temperature Furnaces with Molybdenum Disilicide Heating Elements with Refractory Insulation up to 1700 °C

The high-temperature furnaces HFL 16/16 HFL 160/17 are characterized by their lining with robust light refractory bricks. This version is recommended for processes producing aggressive gases or acids, such as under glass melting.

Standard Equipment

- Like high-temperature furnaces HT, except:

- Tmax 1600 °C or 1700 °C

- Robust refractory brick insulation and special backing insulation

- Furnace floor made of lightweight refractory bricks accommodates high charge weights

- Chain-guided parallel swivel door for defined opening and closing of the door without destroying the insulation

- Labyrinth sealing ensures the least possible temperature loss in the door area

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Like high-temperature furnaces HT

- Protective gas connection to purge with non-flammable protective or reaction gases

- Automatic gas supply system with solenoid valve and rotameter, controlled by the extra function of the controller

- Lift door

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | w | d | h | in l | W | D | H | load in kW | connection | in kg | |

| HFL 16/16 | 1600 | 200 | 300 | 260 | 16 | 1010 | 890 | 1990 | 12 | 3-phase2 | 530 |

| HFL 40/16 | 1600 | 300 | 350 | 350 | 40 | 1140 | 940 | 2260 | 12 | 3-phase | 735 |

| HFL 64/16 | 1600 | 400 | 400 | 400 | 64 | 1240 | 990 | 2310 | 18 | 3-phase | 910 |

| HFL 160/16 | 1600 | 500 | 550 | 550 | 160 | 1410 | 1240 | 2490 | 21 | 3-phase | 1290 |

| HFL 16/17 | 1700 | 200 | 300 | 260 | 16 | 1010 | 890 | 1990 | 12 | 3-phase2 | 530 |

| HFL 40/17 | 1700 | 300 | 350 | 350 | 40 | 1140 | 940 | 2260 | 12 | 3-phase | 735 |

| HFL 64/17 | 1700 | 400 | 400 | 400 | 64 | 1240 | 990 | 2310 | 18 | 3-phase | 910 |

| HFL 160/17 | 1700 | 500 | 550 | 550 | 160 | 1410 | 1240 | 2490 | 21 | 3-phase | 1290 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Heating only between two phases | |||||||||||