Chamber Furnaces up to 1400 °C

Chamber Furnaces up to 1400 °C

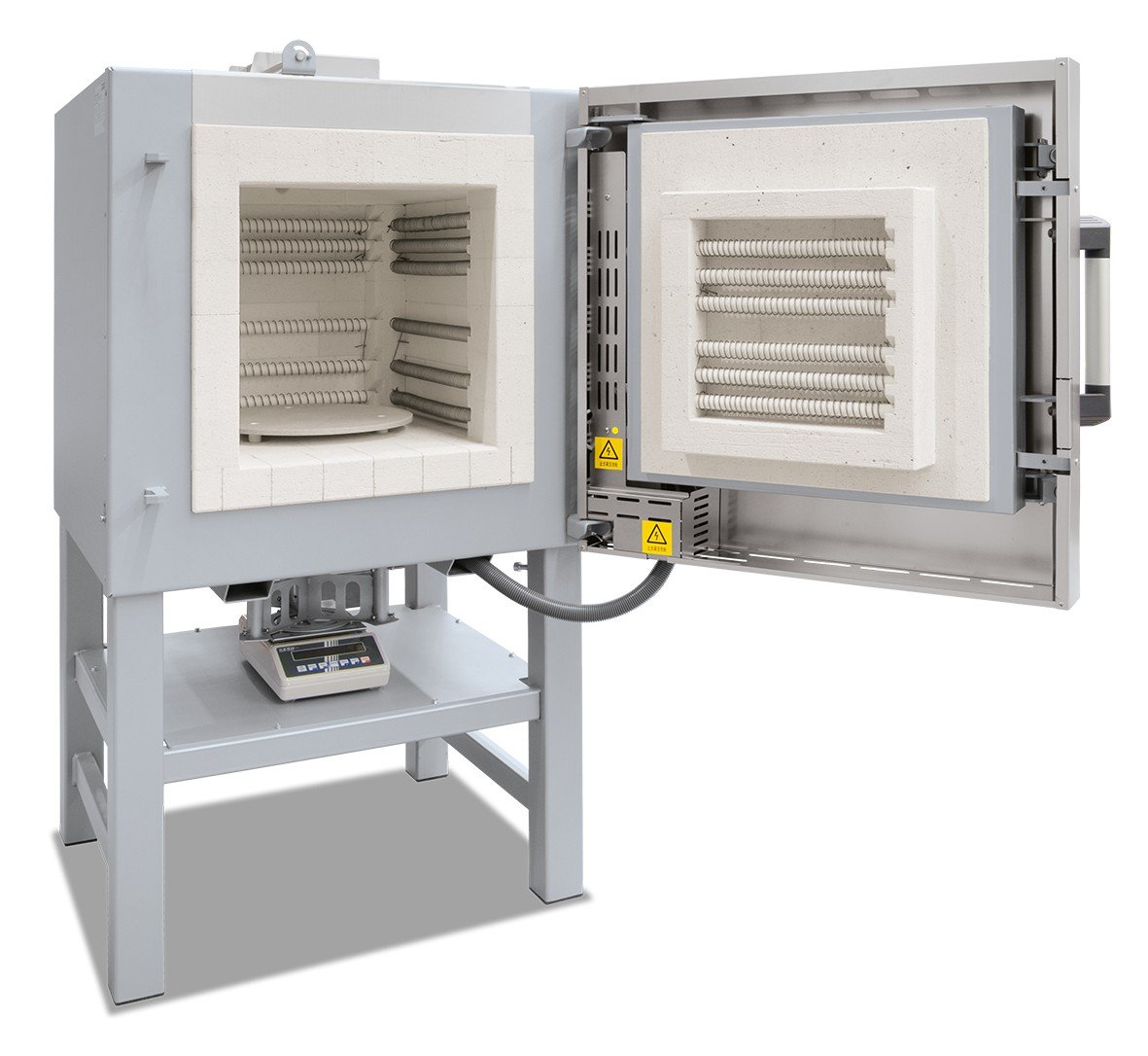

Chamber Furnaces with Brick Insulation or Fiber Insulation up to 1400 °C

These big chamber furnaces LH 15/12 – LF 120/14 have been trusted for many years as professional chamber furnaces for the laboratory. These furnaces are available with either a robust insulation of light refractory bricks (LH models) or with a combination insulation of refractory bricks in the corners and low heat storage, quickly cooling fiber material (LF models). With a wide variety of optional equipment, these chamber furnaces can be optimally adapted to your processes.

Standard Equipment

- Tmax 1200 °C, 1300 °C, or 1400 °C

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- High furnace chamber with five-sided heating for very good temperature uniformity

- Heating elements on support tubes ensure free heat radiation and a long service life

- Controller mounted on furnace door and removable for comfortable operation

- Protection of bottom heating and flat stacking surface provided by embedded SiC plate in the floor

- LH models: multi-layered insulation of light refractory bricks and special backup insulation

- LF models: high-quality fiber insulation with corner bricks for shorter heating and cooling times

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Door with brick-on-brick seal, hand fitted

- Gegenerously dimensioned heating provides for short heating times

- Self-supporting arch for high stability and greatest possible protection against dust

- Motorized exhaust air flaps

- Freely adjustable air inlet integrated in furnace floor

- Base included

- Controller B500 (5 programs with each 4 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Parallel swinging door for opening when hot with hot surface facing away from the operator

- Lift door with electro-mechanic linear drive

- Separate wall-mounting or floor standing cabinet for switchgear

- Cooling system to cool the furnace with a defined temperature gradient or with a preset fresh air volume. Both operating modes can be switched on and off for different segments by means of the extra function of the controller.

- Protective gas connection to purge with non-flammable protective or reaction gases

- Manual or automatic gas supply system

- Scale to measure weight reduction during annealing

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | w | d | h | in l | W | D | H | load in kW | connection* | in kg | |

| LH 15/12 | 1200 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 5.0 | 3-phase2 | 170 |

| LH 30/12 | 1200 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 7.0 | 3-phase2 | 200 |

| LH 60/12 | 1200 | 400 | 400 | 400 | 60 | 790 | 1080 | 1370 | 8.0 | 3-phase | 300 |

| LH 120/12 | 1200 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 12.0 | 3-phase | 410 |

| LH 216/12 | 1200 | 600 | 600 | 600 | 216 | 990 | 1280 | 1590 | 20.0 | 3-phase | 450 |

| LH 15/13 | 1300 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 7.0 | 3-phase2 | 170 |

| LH 30/13 | 1300 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 8.0 | 3-phase2 | 200 |

| LH 60/13 | 1300 | 400 | 400 | 400 | 60 | 790 | 1080 | 1370 | 11.0 | 3-phase | 300 |

| LH 120/13 | 1300 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 15.0 | 3-phase | 410 |

| LH 216/13 | 1300 | 600 | 600 | 600 | 216 | 990 | 1280 | 1590 | 22.0 | 3-phase | 460 |

| LH 15/14 | 1400 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 8.0 | 3-phase2 | 170 |

| LH 30/14 | 1400 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 10.0 | 3-phase2 | 200 |

| LH 60/14 | 1400 | 400 | 400 | 400 | 60 | 790 | 1080 | 1370 | 12.0 | 3-phase | 300 |

| LH 120/14 | 1400 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 18.0 | 3-phase | 410 |

| LH 216/14 | 1400 | 600 | 600 | 600 | 216 | 990 | 1280 | 1590 | 26.0 | 3-phase | 470 |

| LF 15/13 | 1300 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 7.0 | 3-phase2 | 150 |

| LF 30/13 | 1300 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 8.0 | 3-phase2 | 180 |

| LF 60/13 | 1300 | 400 | 400 | 400 | 60 | 790 | 1080 | 1370 | 11.0 | 3-phase | 270 |

| LF 120/13 | 1300 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 15.0 | 3-phase | 370 |

| LF 15/14 | 1400 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 8.0 | 3-phase2 | 150 |

| LF 30/14 | 1400 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 10.0 | 3-phase2 | 180 |

| LF 60/14 | 1400 | 400 | 400 | 400 | 60 | 790 | 1080 | 1370 | 12.0 | 3-phase | 270 |

| LF 120/14 | 1400 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 18.0 | 3-phase | 370 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request.*Please see page 75 for more information about supply voltage | |||||||||||

Chamber Furnaces for Annealing, Hardening and Brazing up to 1280 °C

To withstand harsh use in the laboratory, e.g. when heat-treating metals, robust insulation with light refractory bricks is necessary. The chamber furnaces N 7/H – N 87/H are a perfect fit to solve this problem. The furnaces can be extended with a variety of accessories, like annealing boxes for operation under protective gas, roller guides, or a cooling station with a quench tank. Even high-performance applications like the annealing of titanium in medical applications can be implemented without the use of expensive and complicated annealing systems.

Standard Equipment

- Tmax 1280 °C

- Deep furnace chamber with three-sides heating: from both side walls and bottom

- Heating elements on support tubes ensure free heat radiation and a long service life

- Bottom heating protected by heat-resistant SiC plate

- Temperature uniformity up to +/− 10 °C according to DIN 17052-1

- Low energy consumption due to multi-layer insulation

- Base frame included in the delivery, N 7/H – N 17/HR designed as table-top model

- Parallel guided downward swinging door (user protected from heat radiation)

- Door movement cushioned with gas dampers/struts

- Controller B400 (5 prgrams with each 4 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | Heating time | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | w | d | h | in l | W | D | H | load in kW | connection* | in kg | in min2 | |

| N 7/H | 1280 | 250 | 250 | 140 | 9 | 800 | 650 | 600 | 3.0 | 1-phase | 60 | 320 |

| N 11/H | 1280 | 250 | 350 | 140 | 11 | 800 | 750 | 600 | 3.5 | 1-phase | 70 | 320 |

| N 11/HR | 1280 | 250 | 350 | 140 | 11 | 800 | 750 | 600 | 5.5 | 3-phase3 | 70 | 70 |

| N 17/HR | 1280 | 250 | 500 | 140 | 17 | 800 | 900 | 600 | 6.4 | 3-phase3 | 90 | 110 |

| N 31/H | 1280 | 350 | 350 | 250 | 31 | 1040 | 1030 | 1340 | 15.0 | 3-phase | 210 | 90 |

| N 41/H | 1280 | 350 | 500 | 250 | 41 | 1040 | 1180 | 1340 | 15.0 | 3-phase | 260 | 105 |

| N 61/H | 1280 | 350 | 750 | 250 | 61 | 1040 | 1430 | 1340 | 20.0 | 3-phase | 400 | 105 |

| N 87/H | 1280 | 350 | 1000 | 250 | 87 | 1040 | 1680 | 1340 | 25.0 | 3-phase | 480 | 105 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request.*Please see page 75 for more information about supply voltage 2Heating time of the empty and closed furnace up to Tmax −100 K (connected to 230 V 1/N/PE rsp. 400 V 3/N/PE) 3Heating only between two phases | ||||||||||||

Accessories for the Heat Treatment of Metals

Protective Gas Boxes for Heat Treatment in Protective Gas

By using protective gas boxes, annealing furnaces, forced convection furnaces and pit-type furnaces can be upgraded for heat treatment processes under non-flammable protective and reactive gases.

Annealing Boxes

Annealing boxes are filled with powder or granules into which the charge is placed. Processes like soldering can be carried out in an inexpensive manner.

Complete Workshop Hardening Systems

The Nabertherm compact hardening systems consist of a hardening furnace, a tempering furnace, a quenching and cleaning bath. They can be used for various heat treatment processes in the workshop.

Quenching and Cleaning Baths

Baths for quenching in oil or water as well as for cleaning and degreasing are available as single or double baths and are made of stainless steel.

Auxiliary Materials for Better Charge Results

Hardening foils, annealing bags, granulate

Protective Equipment

Gloves, face and body protection