KJELDAHL DIGESTION SYSTEM – FOR NITROGEN ANALYSIS & PROTEIN DETERMINATION

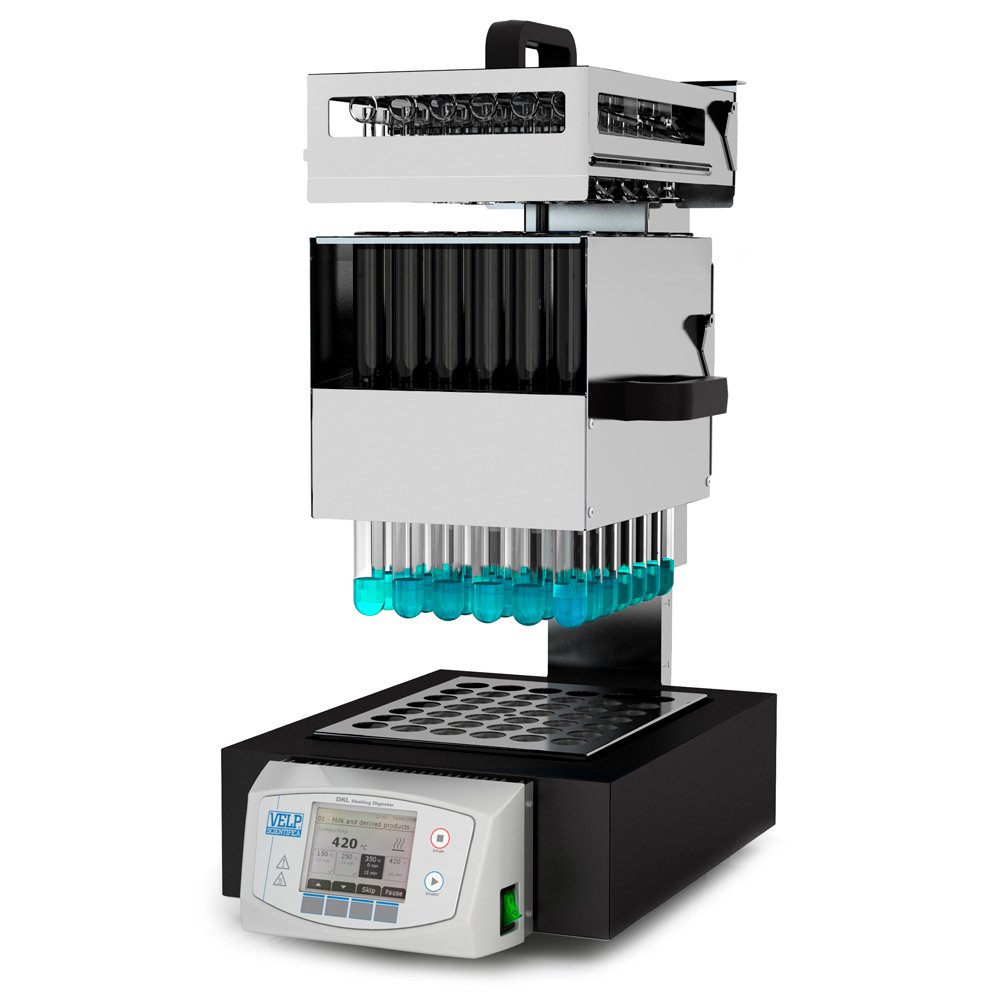

DKL 42/26 Automatic Digestion Unit

Automatic Kjeldahl Digestion Units with 42 positions aluminum heating block that offers excellent thermal stability and homogeneity.

DK 8 Digestion Unit

Kjeldahl Digestion Units with 8-position aluminum heating block that offers an excellent thermal homogeneity.

JP - Recirculating Water Pump

Recirculating Water Pump that ensures optimum fumes aspiration during digestion.

SMS Scrubber

Designed to neutralize corrosive and toxic fumes produced during oxidative mineralizations or similar processes.

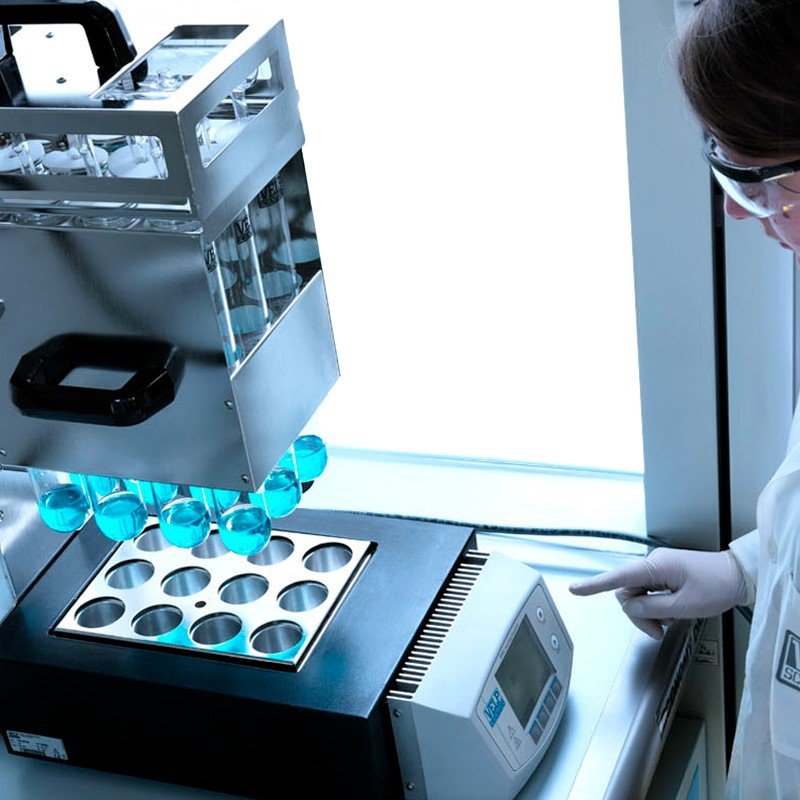

Automatic Digestion Units

Sample preparation is a crucial part of the Kjeldahl analysis in order to obtain accurate and precise results. With the DKL series of digesters, manual operations have been drastically reduced: lowering and lifting of the samples takes place fully automatically, as well as the separation between the test tubes and the suction cup.

You just need to weigh your sample, add the reagents and catalysts and select the method.

DKL 8 (8 positions for 250 ml test tubes, Ø 42 mm)

DKL 12 (12 positions for both 250 and 400 ml test tubes, Ø 42 mm)

DKL 20 (20 positions for both 250 and 400 ml test tubes, Ø 42 mm)

DKL 42/26 (42 positions for 100 ml test tubes, Ø 26 mm)

Walk-away digestion unit to maximize productivity

DKL digesters are fully automatic and immediately ready to use, as they consist of an aluminum heating block, a lift for automatic sample handling, suction hood, test tubes, test tube rack and drip tray.

The DKL series provides the operator with the ultimate technology that allows the laboratory technician to set up the analysis choosing from a library of 54 programs (30 pre-installed + 24 customizable), press START and walk away, boosting the lab productivity.

Ease of loading and unloading make the VELP DKL a pleasure to use when carrying out Kjeldahl analysis, and there is no need to handle the sample when the tubes are hot!

Premium performance with aluminum heating block

DKL extremely fast aluminum heating block is capable of reaching 420°C in just 20 min with best-in-class temperature stability.

The choice of premium materials and the powerful microprocessor guarantee precise block temperature with an accuracy of ± 0.5°C.

Even in terms of repeatability and conductivity, aluminum offers incredibly high performance!

DKL digesters drastically reduce the time needed to reach the digestion temperature according to the Kjeldahl method.

Compact design to save space in your lab

Everybody knows that there is never enough bench space in a laboratory, this is why we have made the DKL series as compact as possible.

The narrow footprint enables you to optimize bench space according to need: fit more instruments on the same lab bench or make different use of the extra space available.

Many labs prefer to perform mineralizations under a fume hood and the compact design of the DKL ensures a minimum use of precious space.

Intuitive operations

Enjoy the simplicity of the DKL’s display. Extremely bright, easy to read and practical with all the fundamental parameters available at a single glance.

Current temperature and ramp settings are clearly viewed on the display. Save up to 54 programs (30 pre-installed, 24 customizable) with up to 4 temperature ramps.

Monitor each stage of analysis as well as select options such as language (including ideograms).

Improved communication leads to improved efficiency.

Fume Neutralization System

For application where the digestion process produces fumes, acid gases or corrosive substances, the below specific accessories are strongly recommended:

- JP Pump aspirates noxious fumes

- SMS Scrubber neutralizes all the fumes

TEMS™ Technology

The DKL series uses the unique TEMS™ technology, which provides significant savings.

Time: fast heating to 420 °C in just 22 minutes, excellent reliability, homogeneity and temperature accuracy.

Energy: reduced consumption by 35%, reduced CO2 emissions by reducing pollution.

Money: significant cost reduction for each analysis, increases the number of analyses without additional costs.

Space: compact profile, minimum use on the bench for optimal laboratory management

COD digestion with DKL 20

DKL 20 is a versatile digester suitable for Kjeldahl N/Protein applications and Chemical Oxygen Demand in the environmental industry.

In order to use the DKL 20 for COD (Chemical Oxygen Demand) is necessary to configure it by adding a different support system able to manage all the glass required for the COD analysis for processing 20 samples simultaneously.

DKL 8

230 V / 50-60 Hz

cod. S30100200

DKL 8

115 V / 50-60 Hz

cod. S30110200

DKL 12

230 V / 50-60 Hz

cod. S30100190

DKL 12

115 V / 50-60 Hz

cod. S30110190

DKL 20

230 V / 50-60 Hz

cod. S30100210

DKL 42/26

230 V / 50-60 Hz

cod. S30100180

TECHNICAL DATA

| CONSTRUCTION MATERIAL: | Stainless steel with chemical resistant coating |

| LIFT AND SUCTION CAP CONTROL | Automatic |

| CONTROL SYSTEM | Microprocessor with LCD graphic display |

| TEMPERATURE RANGE: | Ambient to 450 °C / 842 °F |

| STABILITY OF THE HEATING BLOCK TEMPERATURE: | ± 0,5 °C |

| PRECISION OF THE HEATING BLOCK TEMPERATURE: | ± 0,5 °C |

| SET TEMPERATURE: | Digital readout in °C or °F |

| TEMPERATURE CALIBRATION: | Automatic |

| PROGRAM LIBRARY | 54 Program library, including 24 user-programmable memories |

| SELECTABLE RAMPS: | up to 4 per program |

| DIGESTION TIME RANGE: | 1 to 999 minutes |

| TIME SELECTION: | 1-minute steps |

| COUNTDOWN: | Digital readout |

| SELECTABLE LANGUAGE: | UK, I, E, F, RUS, CN + Additional downloadable |

| INTERFACE | USB to update SW |

| HEATING PLACES | 8-position |

| SIZE OF TUBES | 250 ml test tubes (Ø 42 mm) |

| POWER: | 1150 W |

| DIMENSIONS (WXHXD): | 210x690x540 mm (8.3×27.2×21.3 in) |

| WEIGHT: | 19.7 kg (43.5 lb) |

SAFETY

| OVERTEMPERATURE | Thermostat |

| DAMAGED TEMPERATURE PROBE | Automatic detection and alarm message |

| LIFT MOVEMENT | Visual/acustic signal |

| HOT SURFACE | Visual signal if T>50°C |

Adapter for probe Ø3mm for DK/DKL/ECO

cod. A00000362Glass cap

cod. A00000243IQ/OQ DKL Manual

cod. A00000186KjTabs VCM – 1000 pcs/box

cod. A00000274KjTabs VCT – 1000 pcs/box

cod. A00000276KjTabs VKPC – 1000 pcs/box

cod. A00000275KjTabs VS Antifoam – 1000 pcs/box

cod. A00000283KjTabs VST – 1000 pcs/box

cod. A00000277KjTabs VTCT – 1000 pcs/box

cod. A00000281KjTabs VW – 1000 pcs/box

cod. A00000282Sample rack for DKL8

cod. A00000173Stand for DKL8

cod. A00000184Suction cap and drip tray for DKL8

cod. A00000175Test tubes Ø42×300 mm, 250 ml 3pcs/box

cod. A00000144USB Cable 1,8 mt with filter

cod. 40002309Weighing boats 58x10x10 mm, 100 pcs/box

cod. CM0486000Weighing boats 70x23x15 mm, 100 pcs/box

cod. CM0486001Semi-Automatic Units

DK digesters are traditional digesters, consisting of an aluminum heating block to offer high thermal homogeneity, heating up to 450 °C.

The temperature of the block is constantly controlled by a microprocessor.

The DK Series offers excellent test accuracy and repeatability and is available in the following configurations:

DK 6 (6 positions for 250 ml test tubes, Ø 42 mm)

DK 6/48 (6 positions for 300ml test tubes, Ø 48 mm)

DK 8 (8 positions for 250 ml test tubes, Ø 42 mm)

DK 20 (20 positions for 250 ml test tubes, Ø 42 mm)

DK 20/26 (20 positions for 100 ml test tubes, Ø 26 mm)

DK 42/26 (42 positions for 100 ml test tubes, Ø 26 mm)

Thermal homogeneity and precision

The DK Series digestion unit with aluminium heating block ensures high thermal homogeneity heating up to 450 °C. The temperature of the block is constantly controlled by a microprocessor and is extremely stable, homogeneous and precise: 0.5°C.

The DK Series guarantees accuracy and repeatability. Program your methods with digestion time and up to 4 temperature ramps through the intuitive digital display.

Compact design and maintenance free

DK 6 digestion units have very compact dimensions aimed to reduce the footprint and save space in your lab. The design of the heating block of VELP digestion unit has been studied in order to reduce space under the fume hood.

The DK Series aluminum heating block does not require maintenance. It needs to be combined with a support system, sample rack (with heat shields), suction cap and test tubes (required accessories).

COD digestion with DK 6

DK 6 is a versatile digester suitable for Kjeldahl N/Protein applications and Chemical Oxygen Demand in the environmental industry.

In order to use the DK 6 for COD (Chemical Oxygen Demand) is necessary to configure it by adding a different support system able to manage all the glass required for the COD analysis for processing 6 samples simultaneously.

Fume Neutralization System

For application where the digestion process produces fumes, acid gases or corrosive substances, the below specific accessories are strongly recommended:

- JP Pump aspirates noxious fumes

- SMS Scrubber neutralizes all the fumes

TEMS™ Technology

DK 42/26 Kjeldahl digestion units work with the innovative TEMS™ benefits, for huge savings.

Time Saving: from Ambient to 420 °C in only 35 minutes

Energy Saving: limited energy consumption

Money Saving: cost reduction for each analysis

Space Saving: reduce unnecessary use of space

DK 6

230 V / 50-60 Hz

cod. F30100182

DK 6

115 V / 50-60 Hz

cod. F30110182

DK 6

100 V / 50-60 Hz

cod. F30180182

DK 6/48

230 V / 50-60 Hz

cod. F30100188

DK 6/48

115 V / 50-60 Hz

cod. F30110188

DK 8

230 V / 50-60 Hz

cod. F30100020

DK 8

115 V / 50-60 Hz

cod. F30110020

DK 8

100 V / 50-60 Hz

cod. F30180020

TECHNICAL DATA

| CONSTRUCTION MATERIAL: | Epoxy painted with chemical resistant coating |

| TEMPERATURE RANGE: | Ambient to 450 °C / 842 °F |

| STABILITY OF THE HEATING BLOCK TEMPERATURE: | ± 0,5 °C |

| PRECISION OF THE HEATING BLOCK TEMPERATURE: | ± 0,5 °C |

| SET TEMPERATURE: | Digital readout in °C or °F |

| TEMPERATURE CALIBRATION: | Automatic |

| SELECTABLE RAMPS: | up to 4 per program |

| DIGESTION TIME RANGE: | 1 to 999 minutes |

| TIME SELECTION: | 1 minute steps |

| COUNTDOWN: | Digital readout |

| SELECTABLE LANGUAGE: | UK, I, E, F, D, T |

| HEATING PLACES | 6-position |

| SIZE OF TUBES | 250 ml test tubes (Ø 42 mm) |

| POWER: | 1100 W |

| DIMENSIONS (WXHXD): (ALUMINUM BLOCK ONLY) | 293x152x339 mm (11.5x6x13.3 in) |

| DIMENSIONS (WXHXD): (ALUMINUM BLOCK + SUPPORT SYSTEM) | 295x462x546 mm (11.6×18.2×21.5 in) |

| WEIGHT: | DK 6 16.2 kg (35.7 lb) DK 6/48 15.6 kg (34.4 lb) |

Adapter for probe Ø3mm for DK/DKL/ECO

cod. A00000362Air condenser with ground cone

cod. A00001041Antisplash bell

cod. A00001045COD test tubes Ø 42×200 mm, 200 ml with cone NS 29/32, 3 pcs/box

cod. A00000145Drip tray for DK6-DK6/48

cod. A00001200Glass cap

cod. A00000243IQ/OQ DK Manual

cod. A00000075KjTabs VCM – 1000 pcs/box

cod. A00000274KjTabs VCT – 1000 pcs/box

cod. A00000276KjTabs VKPC – 1000 pcs/box

cod. A00000275KjTabs VS Antifoam – 1000 pcs/box

cod. A00000283KjTabs VST – 1000 pcs/box

cod. A00000277KjTabs VTCT – 1000 pcs/box

cod. A00000281KjTabs VW – 1000 pcs/box

cod. A00000282Null modem connector for printer

cod. A00000010Printer

cod. A00001009PTFE sheaths for 29/32 cones

cod. A00001042Sample rack DK6

cod. A00001111Sample rack DK6 for COD

cod. A00001049Sample rack for DK6/48

cod. A00001113Serial cable RS232

cod. A00000005Stand for DK6-DK6/48-DK20/26

cod. A00001097Suction cap for DK6

cod. A00001096Suction cap for DK6/48

cod. A00001101Support system for DK6-DK20/26-DK6/48

cod. A00001206Test tube Ø48×260 mm, 300 ml

cod. A00001088Test tubes Ø42×300 mm, 250 ml 3pcs/box

cod. A00000144TMD 6

cod. F107C0146Weighing boats 58x10x10 mm, 100 pcs/box

cod. CM0486000Weighing boats 70x23x15 mm, 100 pcs/box

cod. CM0486001

JP - Recirculating Water Pump

Recirculating Water Pump that ensures optimum fumes aspiration during digestion.

Robust and practical design

JP is a water recirculation pump that guarantees optimal suction thanks to the two different programming modes, depending on the digestion phases and the number of samples of the digester to which the pump is connected.

The unit is made of an ABS structure, extremely resistant to chemical corrosion and the type of materials used make the instrument extremely quiet and long-lasting.

The use is facilitated by special technical devices such as the level indicator for water control, the tap for emptying the tank and two convenient handles for handling.

Combined with the special Scrubber SMS, JP provides the ideal complement for a very effective abatement of fumes developed during acid digestions.

Water consumption

JP Pump provides a considerable water saving thanks to the principle of continuous water recirculation in its tank which results in considerable savings. It is designed to offer high performance in terms of efficiency: up to 35 l/min flow rate.

The use of common water pumps is frequently prevented by the lack of adequate water pressure or high water consumption.

JP

230 V / 50 Hz

cod. F30620198

JP

230 V / 60 Hz

cod. F30630198

JP

115 V / 60 Hz

cod. F30640198

GENERAL FEATURES

| CONSTRUCTION MATERIAL: | ABS |

| MAXIMUM AIR FLOW: | 35 l/min |

| FLOW REGULATION: | from 0 to 35 l/min |

| RESIDUAL PRESSURE WITH WATER TEMPERATURE OF 15°C: | 35 mm Hg |

| POWER: | 160 W |

| WEIGHT: | 8,4 Kg (18.5 lb) |

| DIMENSIONS (WXHXD): | 250x400x370 mm (9.8×15.7×14.6 in) |

IQ/OQ JP Manual

cod. A00000253

SMS Scrubber

Designed to neutralize corrosive and toxic fumes produced during oxidative mineralizations or similar processes.

Highly efficient fumes neutralization in 3 stages

The SMS Scrubber is designed to neutralize corrosive and toxic fumes developed during oxidative mineralization or other processes, such as digestion.

Its working process is generally composed of 3 stages:

– condensation

– neutralization with acids and bases

– absorption with activated carbon (optional – ideal for high fume levels such as with soybean analysis)

Thanks to the elevated surface of contact between gas and liquid, SMS scrubber has a wide range of applications and provides its maximum efficiency when combined with the JP Water Recirculation Pump for smoke suction.

SMS

cod. F307C0199

TECHNICAL DATA

| CONSTRUCTION MATERIAL: | Stainless steel structure |

| WEIGHT: | 3,5 Kg (7.7 lb) |

| DIMENSIONS (WXHXD): | 190x500x300 mm (7.5×19.7×11.8 in) |

Filter for actived carbon

cod. A00001165IQ/OQ SMS Manual

cod. A00000252Pack of 10 refill of actived carbon

cod. A00001164