Octane and Cetane Analyzer

Petroleum Test and Oil Test Equipment

SHATOX SX-150

SHATOX SX-250

SHATOX SX-300

SHATOX SX-100K

SHATOX SX-100M

SHATOX SX-200

SHATOX SX-150 portable octane/cetane analyzer

SHATOX SX-150 instrument can be used together with a PC a laptop through USB interface. Analyzer can save measured data in the instrument memory with analysis date and time and then transfer the readings to a computer (in Microsoft Excel or txt format).

SHATOX SX-150 portable octane and cetane analyzer

New oil products grade analyzer is manufactured on the basis of advanced high precision microprocessor. the instrument can be used together with a PC a laptop through USB interface. Analyzer can save measured data in the instrument memory with analysis date and time and then transfer the readings to a computer (in Microsoft Excel or txt format).

When determining petrol breakdown time, the petrol brand is selected in the instrument. The instrument switches to corresponding operating mode. Oxidative stability determination complies with GOST 4039-88 (ASTM D 525)

The instrument uses the timer microchip, which allows storing measurement results with analysis date and time. These data can also be transmitted to a computer.

New computer software is included into the set.

– measurement results are reflected on computer screen in convenient form;

Instrument capabilities:

Determining octane numbers for motor petrols. Complies with ASTM D 2699-86, ASTM D 2700-86.

Determining cetane numbers for diesel. Complies with ASTM D 4737-03, ASTM D 613, EN ISO 5165.

Determining solidification temperature and diesel fuel type.

Content of pour-point depressants for diesel fuels.

Content of kerosine in diesel fuel.

Parameter description | Measurement units | Value |

Measured petrols octane numbers range | ON | 40-125 |

Acceptable limit of octane number measurement basic error, max | ON | ± 0.5 |

Limit of acceptable difference between parallel octane number measurements, max | ON | ± 0.2 |

Petrol oxidation breakdown time measurement range | min | 50-2400 |

Acceptable basic error limit of petrol oxidation breakdown time | % | 5 |

Cetane numbers measurement range | CN | 20-100 |

Acceptable basic error limit of cetane numbers, max | CN | ±1.0 |

Acceptable difference limit between cetane numbers parallel measurements, max | CN | ± 0.5 |

Acceptable error limit when determining diesel-fuel pour point | C o | ± 2 |

Kerosine content determination range in diesel fuels | % | 0-95 |

Mode for pour point depressants content determination for diesel fuel | % | 3 |

Acceptable basic error limit when determining kerosene content in diesel fuels | % | 0.2-1 |

Acceptable basic error limit when determining of pour point depressants content | % | 0.01 |

Measurement times | Sec | 1-5 |

Insufficient power supply indication operation threshold | V | 5.4 |

Instrument useful life | Years | 6 |

Overall dimensions of: |

|

|

Electronic module | mm | 211x100x45 |

Sensor #1 and #2 | mm | 60×100 |

Instrument mass with one sensor/two sensors | gr | 850 |

Delivery package:

Electronic computing module

Detector #1

Sample imitator

Software disk

mini-USB cable

Operations manual

Certification

Warranty certificate

Tool canvas bag

SHATOX SX-250 portable octane/cetane analyzer

SX-250 has the mode for determining the purity of mineral, synthetic, industrial oils, the mode for measuring dielectric permeability of oil products, as well as the mode for determining water content in diesel.

SHATOX SX-250 portabe octane and cetane analyzer

New oil products grade analyzer is manufactured on the basis of advanced high precision microprocessor. This model is designed for the operation with fuels and oils. It continues the series “2xx” (fuel and oil quality analysis). Additionally, SX-250 has the mode for determining the purity of mineral, synthetic, industrial oils, the mode for measuring dielectric permeability of oil products, as well as the mode for determining water content in diesel.

The instrument can be used together with a PC a laptop through USB interface. Analyzer uses automatic computer-based calibration, saving measured data in the instrument memory with analysis date and time followed by their transfer to the PC (in Microsoft Excel or txt format). The instrument has easy of control attrition and aggressive environments resistive 8-key antiglare keyboard (made in Germany).

When determining petrol breakdown time, the petrol brand is selected in the instrument. The instrument switches to corresponding operating mode. Oxidative stability determination complies with GOST 4039-88 (ASTM D 525)

The instrument uses the timer microchip, which allows storing measurement results with analysis date and time. These data can also be transmitted to the computer.

New computer software is included into the set.

– measurement results are reflected on computer screen in convenient form;

Instrument capabilities:

- Determining gasoline octane level. Complies with ASTM D 2699-86, ASTM D 2700-86.

- Determining diesel fuel cetane level. Complies with ASTM D 4737-03, ASTM D 613, EN ISO 5165.

- Determining solidification temperature and diesel fuel type (reference parameter).

- Determining content of kerosene in diesel fuel (reference parameter).

- Determining petrol breakdown time (oxidative stability). Complies with ASTM D 525.

- Determining purity (purification) level of transformer, industrial and motor oil

- Determining dielectric permeability of oil products (Eps)

- Determining water content in diesel (%)

| Parameter description | Measurement units | Value |

Range of measured gasoline octane level | ON | 40–135 |

Acceptable limit of octane number measurement basic error, max | ON | ± 0.5 |

Limit of acceptable difference between parallel octane number measurements, max | ON | ± 0.2 |

Petrol oxidation breakdown time measurement range | min. | 50-2400 |

Acceptable basic error limit of petrol oxidation breakdown time | min. | 10 |

Range of measured cetane level | CN | 20–100 |

Acceptable basic error limit of cetane numbers, max | CN | ±1.0 |

Acceptable difference limit between cetane numbers parallel measurements, max | CN | ± 0.5 |

Acceptable error limit when determining diesel-fuel pour point | C o | ± 5 |

Kerosene content determination range in diesel fuels | % | 0-95 |

Acceptable basic error limit when determining kerosene content in diesel fuels | % | 3 |

Range of measured purity of motor oils | % | 95-100 |

Acceptable basic error limit when determining purity of motor oils | % | 0.01 |

Range of measured dielectric permeability of oil products | units | 1-5 |

Range of measured water content in diesel | % | 0-4 |

Acceptable basic error limit when determining water content in diesel | % | 0.01 |

Measurement time | sec | 1–5 |

Insufficient power supply indication operation threshold | V | 5.4 |

Instrument useful life | Years, minimum | 6 |

Overall dimensions of: |

|

|

electronic module | mm | 211x100x45 |

sensor #1 | mm | 60х100 |

Instrument mass with a sensor | gr | 680 |

Delivery package:

- Electronic computing module

- Sensor #1

- Sample imitator

- Software disk

- Mini-USB cable

- Operations manual

- Quick start guide

- Warranty certificate

- Tool canvas bag

SHATOX SX-300 portable petroleum quality analyzer

Analyzer SX-300 has a distinctive characteristic, an additional sensor, which measures oil products volume resistivity with high precision.

SHATOX SX-300 Petroleum Quality Analyzer

New oil products grade analyzer is manufactured on the basis of advanced high precision microprocessor. the instrument can be used together with a PC a laptop through USB interface. Analyzer uses automatic computer-based calibration, saving measured data in the instrument memory with analysis date and time followed by their transfer to the PC (in Microsoft Excel or txt format). The instrument has easy of control attrition and aggressive environments resistive 8-key antiglare keyboard (made in Germany).

Analyzer SX-300 has a distinctive characteristic, an additional sensor, which measures oil products volume resistivity with high precision. Therefore, fuel analysis may be based on two values, which allows measuring octane number of petrols with ferriferous (ferrocene), nickel and manganese additives, and to determine other substances content.

By using this measurement principle the instrument allows to determine:

- contamination content in oil products;

- pour-point depressants content in diesel fuel;

- engine oil base number;

- oil products volume resistivity.

When determining petrol breakdown time, the petrol brand is selected in the instrument. The instrument switches to corresponding operating mode. Oxidative stability determination complies with GOST 4039-88 (ASTM D 525)

Motor oil brand identification is based on the permittivity determination principle. Genuine motor oils have certain value for this characteristic. Leading manufacturers’ oil brands are included into the instrument database (the database can be renewed or changed).

Water-in-oil percentage of oil and oil products is determined in compliance with GOST 14203-69 (Dielectric humidity measuring method). This allows using the instrument as a dielectric moisture indicator for oil products.

The instrument uses the timer microchip, which allows storing measurement results with analysis date and time. These data can also be transmitted to the computer.

New computer software is included into the set.

– measurement results are reflected on computer screen in convenient form;

Instrument capabilities:

Determining octane numbers for motor petrols. Complies with ASTM D 2699-86, ASTM D 2700-86.

Determining cetane numbers for diesel. Complies with ASTM D 4737-03, ASTM D 613, EN ISO 5165.

Determining water-in-oil percentage of oil and oil products. Complies with GOST 14203-69 Oil and oil products. Dielectric humidity measuring method.

Determining solidification temperature and diesel fuel type.

Content of antiknock compounds boosting the octane number of petrols.

Content of pour-point depressants for diesel fuels.

Content of kerosine in diesel fuel.

Petrol breakdown time (oxidative stability). Complies with ASTM D 525.

Loss angle tangent of circuit-breaker, machine and engine oil.

Level of engine, machine and circuit-breaker oil clarity.

Manufacturer, engine oil brand.

Engine oil base number.

Dielectric permeability of oil products.

Oil products volume resistivity.

Determining the mechanical impurities content in oil products.

Determining water-in-oil percentage of oil and oil products. Complies with GOST 14203-69 Oil and oil products. Dielectric humidity measuring method.

| Parameter description | Measurement units | Value |

|---|---|---|

| Measured petrols octane numbers range | ON | 40–125 |

| Acceptable limit of octane number measurement basic error, max | ON | ± 0.5 |

| Limit of acceptable difference between parallel octane number measurements, max | ON | ± 0.2 |

| The determination range of antiknock additives content in petrols | % | 0.5-15 |

| Acceptable basic error limit of antiknock additives content determination in petrols | % | 0.1 |

| Petrol oxidation breakdown time measurement range | min. | 50-2400 |

| Acceptable basic error limit of petrol oxidation breakdown time | % | 5 |

| Petrol quality determination mode basing on volume resistivity | Om | 10 6-10 14 |

| Acceptable basic error limit of volume resistivity measurements | % | 3 |

| Cetane numbers measurement range | CN | 20–100 |

| Acceptable basic error limit of cetane numbers, max | CN | ±1.0 |

| Acceptable difference limit between cetane numbers parallel measurements, max | CN | ± 0.5 |

| Acceptable error limit when determining diesel-fuel pour point | C o | ± 2 |

| Kerosine content determination range in diesel fuels | % | 0-95 |

| Mode for pour point depressants content determination for diesel fuel | % | 3 |

| Acceptable basic error limit when determining kerosene content in diesel fuels | % | 0.2-1 |

| Acceptable basic error limit when determining of pour point depressants content | % | 0.01 |

| Motor oils clarity level measurement range | % | 95-100 |

| Acceptable error limit of motor oils clarity level measurement | % | 0.1 |

| Acceptable difference limit between motor oils clarity parallel measurements | % | 0.01 |

| POL dielectric permeability measurement range | Unit | 1–5 |

| Acceptable error limit of dielectric permeability measurement, max | Unit | 0.001 |

| Acceptable difference limit between POL dielectric permeability parallel measurements, max | Unit | 0.001 |

| Oils base number determination range | Unit | 0-24 |

| Acceptable basic error limit when determining oils basic number | BN unit | 1 |

| Motor oils manufacturer and brand determination | Manufacturer | – |

| Circuit-breaker oils (dielectrics) breakdown voltage measurement range | kV | 5–100 |

| Acceptable error limit of circuit-breaker oils breakdown voltage measurement, max | kV | 1 |

| Acceptable difference limit between circuit-breaker oils breakdown time parallel measurements, max | kV | 0.2 |

| Measurement range of circuit-breaker oils loss angle tangen | % | 0.01–40 |

| Acceptable error limit of circuit-breaker oils loss angle tangent, max | % | 0.01 |

| Acceptable difference limit between circuit-breaker oils loss angle tangent parallel measurements, max | Unit | 0.001 |

| Determination range for mechanical impurities content in oil products | % | 97-100 |

| Acceptable basic error limit when determining mechanical impurities content in oil products | % | 0.01 |

| Water-in-oil content determination range for oil products | % | 0-30 |

| Acceptable basic error limit when determining water-in-oil content of oil products | % | 1 |

| Measurement time | s | 1–5 |

| Insufficient power supply indication operation threshold | V | 5.4 |

| Instrument useful life | years | 6 |

| Overall dimensions of: | ||

| electronic module | mm | 211x100x45 |

| sensor #1 and #2: | mm | 60х100 |

| Instrument mass with one sensor/two sensors | gr | 850 |

Delivery package:

Electronic computing module

Detector #1

Detector #2

Sample imitator for detector #1

Software disk

mini-USB cable

Operations manual

Certification

Warranty certificate

Tool canvas bag

SHATOX SX-100K portable octane analyzer with PC interface

The operational principle of the Octane Meter lies in gasoline octane rating and diesel fuel cetane rating based on the analysis of change of properties of an dielectric permeability and electromagnetic induction.

SHATOX SX-100K

Portable octane analyzer is used for instant octane rating of motor gasoline, corresponding to motor and research methods (RON and MON) as well as for cetane number of diesel fuels. In addition for an inquiries, temperature rating of the analyzed liquid and diesel fuel solidification is provided. The results of measuring are displayed on the LCD.

The operational principle of the Octane Meter lies in gasoline octane rating and diesel fuel cetane rating based on the analysis of change of properties of an dielectric permeability and electromagnetic induction.

Octane analyzer has the portable compact design and is used for on-line inspection of motor fuel quality in the field and laboratory conditions. The operating conditions of the Octane analyzer usage: ambient temperature from –10C to +30C, relative humidity 80% at 25 C, atmosphere pressure 84-106kPa. The device gets power from DC elements of type AA (supply voltage 6V).

Advantages of Octanemeter SX-100K

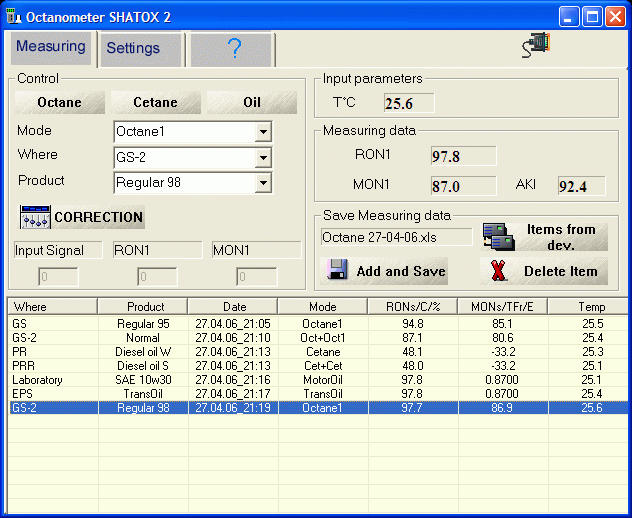

You can take measurements and make the measurement table in Microsoft Excel format which include the information about sample at the same time;

The correction of the measurment become much easier;

The information about the work of octane tester, correction, and measurment data are display on the screen of the computer;

Capability to update fuel parameters database (make an individual measurement program for customer needs).

.png)

Capabilities:

| Parameter | Description | According |

|---|---|---|

| Measurement of octane level. | Research (RON), motor (MON) method. Anti Knocking Index AKI (Pump octane number PON). | ASTM D 2699-86, ASTM D 2700-86. |

| Measurement of cetane level. | Simultaneously with cetane number the type and temperature of hardening of diesel fuel is defined. | ASTM D 4737-03, ASTM D 613, EN ISO 5165. |

| Measurement freezing-point of diesel fuel. | It is defined depending on cetane numbers of diesel fuel. | Facultative parameter. |

| Measurement type of diesel fuel. | Type of diesel fuel. (S-summer, W-winter, A-arctic) is defined depending on temperature of hardening. | Facultative parameter. |

| Parameter description | Value |

|---|---|

| Types of controlled fuel | all types of gasoline |

| Range of measured octane level | 40-120 |

| Range of measured cetane level | 20-100 |

| Measurement inaccuracy of octane number | 0,5 |

| Measurement inaccuracy of cetane number | 1 |

| Data display | digital |

| Time of measurement, sec | below 10 |

| Consumption current, mA | 30 |

| Time of continuous running with one set of batteries, hour | 100 |

| Operation temperature range | -100С…+40 0С |

| Relative humidity, % | 30…..80 |

| Atmosphere pressure, kPascal | 64…..106 |

Dimension, mm:

| 60 х 100 211 x 100 x 45 |

| Weight, gr | 680 |

| Mean-time-between-failures, hour | >1000 |

The delivery package consists of the following components:

- Electronic unit;

- Sensor;

- Sample imitator;

- User manual;

- RS 232 computer connecting cable;

- Software CD;

- Tool canvas bag;

SHATOX SX-100M portable octane/cetane analyzer

Octane Meter SX-100M in comparison with the base model has: more durable case, more integral parameters of the gasoline and diesel fuel types, four line LCD which displays at the same time the octane number of the analyzed sample by research and motor methods, and temperature of the sample. Cetane number and freezing temperature (as option) is displayed during the analysis of diesel fuel.

Octane Meter is developed in Petroleum Chemisorption Institute of Siberian Branch of Russian Academy of Science. The fuel quality analyzer Octane Meter is intended for evaluation of the type of gasoline, and determination of its octane number. The Octane Meter also determines the cetane number of diesel fuel.

Equally good the Octane Meter measures the parameters of the leaded and unleaded gasoline, as well as the gasoline with different additives. 10 seconds is the maximum time to detect the type of gasoline at the worst conditions (cold start). The entire process is automated – the operator only needs to fill the sensor with the gasoline, turn on the instrument, and write down the results from the display.

The Octane Meter is simple in use, and does not require regular adjustments and special maintenance. The use of the Octane Meter eliminates the human factor during the quality estimation of the oil products. It’s recommended to use the instrument at petroleum storages, filling stations, customs houses, and for the check of the samples in gasoline production lines.

The measurement principle of the octane level is based on a comparative analysis between the parameters of the analyzed gasoline and the reference gasoline parameters stored in the microprocessor’s memory.

The design of the instrument and the measurement algorithm provides a high-level noise immunity and, as a result, a stable measurement. During gasoline blending octane level can be controlled within the range from 40 to 120. There is an option to adjust the instrument for a nonstandard fuel, for example, natural (gaseous condensate) or virgin gasoline. An advanced user can perform such an adjustment without assistance of the instrument maker.

Note:

Inaccuracy of repeated measurements does not exceed 0.5 unit of octane level.

Absolute error, determined by comparison the Octane Meter indications and indications of stationary instrument in the laboratory environment does not exceed 0.5 unit of octane level.

Octane Meter was registered in public register ( 33552-2007 certification № 26305) and permitted for use in Russian Federation based on the positive results of the tests.

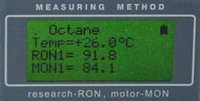

Octane Meter SX-100M

Octane Meter SX-100M in comparison with the base model has: more durable case, more integral parameters of the gasoline and diesel fuel types, four line LCD which displays at the same time the octane number of the analyzed sample by research and motor methods, and temperature of the sample. Cetane number and freezing temperature (as option) is displayed during the analysis of diesel fuel.

Octane Meter SX-100M has 6 modes of operation, 3 of them are general:

- the base mode, for the determination of the ON of standard gasoline;

- the mode for the analysis of low octane gasoline produced by blending, and also for gasoline with the 95 octane number;

- for the analysis of the cetane number of diesel fuel.

Because the octane and cetane number are determined by estimation of integral content of the fuel sample, indications of Octane Meter can be different for two gasoline samples of the same type but produced by different manufacturer. For this Octane Meter SX-100M has 3 additional modes that are analogous with the first three, but are intended for making corrections by the user. At the same time the user corrected algorithm is stored in the memory of octanemeter after it is switched off.

Advantages of octane/cetane analyzers SHATOX:

More comprehensive and accurate analysis of petroleum products;

Accuracy of repeated measurements is 0.5 octane number unit;

Absolute error is close to one of stationary unit, and not more than 0.5 octane number unit;

Analyses gasoline with any additives, including metal knockers, ethers, amines, and others;

New powerful microchip for rapid and accurate result processing;

Displays RON, MON and Anti Knocking Index AKI (RON+MON)/2 at the same time;

Analyzes cetane number, diesel fuel type and freezing temperature;

WINDOWS 95, 98, ME, 2000, XP Compatible;

Saves analysis results in nonvolatile RAM;

Accurate measurement correction with digital thermometer according to the temperature of the sample;

Simple in use;

Small volume of sample;

Low cost of analysis;

Compactness and portability;

Impact-resistant, solvent-resistant, tight case;

4 row LCD with backlight and resistant to low temperatures;

Battery charge indicator;

Low voltage power supply;

External power supply unit.

The instrument surpasses by its capabilities other Octane Meters because it allows to measure gasoline with any additives including metal-detonation, ether, amine, etc (except ferrocene).

Capabilities:

| Parameter | Description | According |

|---|---|---|

| Measurement of octane level. | Research (RON), motor (MON) method. Anti Knocking Index AKI (Pump octane number PON). | ASTM D 2699-86, ASTM D 2700-86. |

| Measurement of cetane level. | Simultaneously with cetane number the type and temperature of hardening of diesel fuel is defined. | ASTM D 4737-03, ASTM D 613, EN ISO 5165. |

| Measurement freezing-point of diesel fuel. | It is defined depending on cetane numbers of diesel fuel. | Facultative parameter. |

| Measurement type of diesel fuel. | Type of diesel fuel. (S-summer, W-winter, A-arctic) is defined depending on temperature of hardening. | Facultative parameter. |

| Parameter description | Value |

|---|---|

| Types of controlled fuel | all types of gasoline |

| Range of measured octane level | 40-120 |

| Range of measured cetane level | 20-100 |

| Measurement inaccuracy of octane number | 0,5 |

| Measurement inaccuracy of cetane number | 1 |

| Data display | digital |

| Time of measurement, sec | below 10 |

| Consumption current, mA | 30 |

| Time of continuous running with one set of batteries, hour | 100 |

| Operation temperature range | -100С…+40 0С |

| Relative humidity, % | 30…..80 |

| Atmosphere pressure, kPascal | 64…..106 |

Dimension, mm:

| 60 х 100 211 x 100 x 45 |

| Weight, gr | 680 |

| Mean-time-between-failures, hour | >1000 |

Delivery package:

The electron circuit is made from European and Japanese details. The case of Octane Meter – K and Octane Meter SX-100M is made from shock-proof and gasoline-proof polystyrene. The instrument is powered from AA batteries, and because of low voltage it is electrically safe.

- Electronic unit;

- Sensor;

- Sample imitator;

- User manual;

- Tool canvas bag;

SHATOX SX-200 portable octane tester

The Octane Tester SX-200 is recommended for the use at filling stations, petroleum refineries, Custom-houses, environmental and supervisory organizations, electric power stations as a portable universal device to control fuel and oil quality.

A modification of the universal fuel and oil quality analyzer Octane Tester SX-200 is intended for detection of type and measurement of octane number of gasoline, cetane number of diesel fuel, and also for estimation of diesel fuel freezing temperature, purity level, and quality of motor, industrial and transformer (dielectric puncture potential) oil.

In Octane Tester SX-200 accurate sample temperature adjustment is implemented with the use of digital thermometer. In the analyzer’s memory measurement results can be stored and transferred to a PC.

Capability to make an individual measurement program (according to customer’s requirements) allows to adjust the instrument to analyze the quality of any gasoline. New microprocessor is used for quick and accurate processing in analyzer. The device measures and displays octane number RON, MON and antiknock index AKI (RON+MON)/2 simultaneously. The instrument has additional 220V power supply, battery charge indicator, display backlight.

The Octane Tester SX-200 is recommended for the use at filling stations, petroleum refineries, Custom-houses, environmental and supervisory organizations, electric power stations as a portable universal device to control fuel and oil quality.

Octane Tester capabilities:

Measurement of octane level. According ASTM D 2699-86, ASTM D 2700-86;

Measurement of cetane level. According ASTM D 4737-03, ASTM D 613, EN ISO 5165;

Measurement of freezing-point of diesel fuel and type;

Motor oil purity level measurement;

Transformer oil disruption voltage measurement;

Transformer oil dielectric dissipation measurement;

Fuel and oil dielectric conductivity measurement.

| Parameter description | Value |

|---|---|

| Measurement range of octane numbers (ON), ON units | 40-120 |

| Acceptable limit of octane number measurement basic error, ON units (max) | 0.5 |

| Limit of acceptable difference between parallel octane number measurements, ON units (max) | ±0.2 |

| Measurement range of cetane numbers (CN), CN units | 20-100 |

| Acceptable limit of cetane number measurement error, CN units (max) | ±1.0 |

| Limit of acceptable difference between parallel cetane number measurements, CN units (max) | ± 0.5 |

| Motor oil purity level measurement range, % max | 95 |

| Acceptable limit of motor oil purity level measurement error, % max | 0.1 |

| Limit of acceptable difference between parallel motor oil purity level measurements, % max | 0.01 |

| Fuel and oil dielectric conductivity measurement range, units | 1-5 |

| Acceptable limit of dielectric conductivity measurement error, units (max) | 0.001 |

| Limit of acceptable difference between parallel dielectric conductivity measurements, units (max) | 0.001 |

| Transformer oil disruption voltage measurement range, kV | 5-100 |

| Acceptable limit of transformer oil disruption voltage measurement error, kV (max) | 1 |

| Limit of acceptable difference between parallel transformer oil disruption voltage measurements, V (max) | 0.2 |

| Transformer oil dielectric dissipation measurement range, % | 0.01-5 |

| Acceptable limit of transformer oil dielectric dissipation measurement error, % | 0.01 |

| Limit of acceptable difference between parallel transformer oil dielectric dissipation measurements, units (max) | 0.001 |

| Measurement time, s | 1-5 |

| Threshold of low battery voltage indication, V | 5.4 |

overall dimensions

|

60 х 100 |

| Mass of octanemeter, gr | 680 |

| Mean-time-between-failures, hour (min) | 1000 |

The delivery package of Octane Meter SX-200 consists of the following components:

- Electronic unit;

- Sensor;

- Sample imitator;

- User manual;

- RS 232 computer connecting cable;

- Software CD;

- Tool canvas bag.