Tube Furnaces up to 1800 °C

Tube Furnaces up to 1800 °C

Compact Tube Furnaces up to 1100 °C

The RD 30/200/11 tube furnace impresses with its very good price-performance ratio, particularly compact external dimensions and its low weight. This all-rounder is equipped with a working tube, which also serves as support for the heating wires. The working tube is therefore part of the furnace heating, with the advantage that the tube furnace reaches very high heating speeds. The furnace is designed for horizontal use up to 1100 °C.

Standard Equipment

- Tmax 1100 °C

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Inner diameter of the tube: 30 mm, heated length: 200 mm

- Ceramic working tube C 530 including two fiber plugs for operation under air

- Thermocouple type K (1100 °C)

- Solid state relays provide for lownoise operation

- Heating wires wound directly around the working tube resulting in very fast heat-up rates

- Defined application within the constraints of the operating instructions

- Controller R7

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Gas supply system 1 for non-flammable protective or reactive gas

| Model | Tmax1 | Outer dimensions2 in mm | Inner tube Ø | Heated length | Length constant | Connected | Heating time3 | Electrical | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | W | D | H | in mm | in mm | temperature1 +/− 5 K in mm | load in kW | in min | connection* | in kg | |

| RD 30/200/11 | 1100 | 350 | 200 | 350 | 30 | 200 | 65 | 1.5 | 20 | 1-phase | 12 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K*Please see page 75 for more information about supply voltage 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 3Heating time of the empty and closed furnace up to Tmax −100 K (connected to 230 V 1/N/PE) | |||||||||||

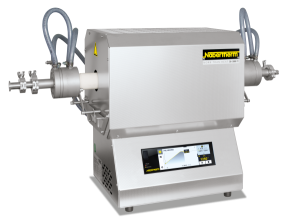

Compact Tube Furnaces up to 1300 °C

These compact tube furnaces with integrated control systems can be used universally for many processes. Equipped with a standard working tube of C 530 ceramic and two fiber plugs, these tube furnaces have a very good price/performance ratio.

Standard Equipment

- Tmax 1200 °C or 1300 °C

- Single-zoned design

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Outer tube diameter of 50 mm to 170 mm, heated length from 250 mm to 1000 mm

- Ceramic working tube C 530 including two fiber plugs for operation under air

- Thermocouple type N (1200 °C) or type S (1300 °C)

- Solid state relays provide for lownoise operation

- Heating elements on support tubes provide for free radiation

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller B510 (5 programs with each 4 segments)

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Charge control with temperature measurement in the working tube

- Three-zoned design (heated length from 500 mm) for optimization of temperature uniformity

- Gas supply systems 1, 15, 2, 3 or 4

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax1 | Outer dimensions3 in mm | Outer tube Ø | Heated | Length constant1 | Tube length | Connected | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| length | temperature +/− 5 K in mm | load | ||||||||||

| in °C | W2 | D | H | in mm | in mm | single-zoned | three-zoned | in mm | in kW | connection* | in kg | |

| R 50/250/12 | 1200 | 434 | 340 | 508 | 50 | 250 | 80 | – | 450 | 1.6 | 1-phase | 22 |

| R 50/500/12 | 1200 | 670 | 340 | 508 | 50 | 500 | 170 | 250 | 700 | 2.34 | 1-phase | 34 |

| R 120/500/12 | 1200 | 670 | 410 | 578 | 120 | 500 | 170 | 250 | 700 | 6.5 | 3-phase | 44 |

| R 170/750/12 | 1200 | 920 | 460 | 628 | 170 | 750 | 250 | 375 | 1070 | 10.0 | 3-phase | 74 |

| R 170/1000/12 | 1200 | 1170 | 460 | 628 | 170 | 1000 | 330 | 500 | 1400 | 11.5 | 3-phase | 89 |

| R 50/250/13 | 1300 | 434 | 340 | 508 | 50 | 250 | 80 | – | 450 | 1.6 | 1-phase | 22 |

| R 50/500/13 | 1300 | 670 | 340 | 508 | 50 | 500 | 170 | 250 | 700 | 2.34 | 1-phase | 34 |

| R 120/500/13 | 1300 | 670 | 410 | 578 | 120 | 500 | 170 | 250 | 700 | 6.5 | 3-phase | 44 |

| R 170/750/13 | 1300 | 920 | 460 | 628 | 170 | 750 | 250 | 375 | 1070 | 10.0 | 3-phase | 74 |

| R 170/1000/13 | 1300 | 1170 | 460 | 628 | 170 | 1000 | 330 | 500 | 1400 | 11.5 | 3-phase | 89 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 *Please see page 75 for more information about supply voltage 2Without tube 4Only valid for single-zone version 3External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. | ||||||||||||

Split-Type Tube Furnaces for Horizontal or Vertical Operation up to 1300 °C

These tube furnaces can be used for horizontal (RSH) or vertical (RSV) operation. The split-type design makes it easy to change the working tube. It allows for a comfortable exchange of various working tubes (e.g. working tubes made of different materials).

Using a wide range of accessories, these professional tube furnaces can be optimally tailored for your process. By adding different gas supply packages, you can work in a protective gas atmosphere, with gases or in a vacuum. In addition to the convenient standard controllers, modern PLC controls can also be used to control the process.

Standard Equipment

- Tmax 1100 °C or 1300 °C

- Single-zoned design

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- RSV models with frame for vertical operation

- Split-type design for simple insertion of the working tube (opening temperature < 180 °C)

- Ceramic working tube C 530 including two fiber plugs for operation under air

- Thermocouple type N (1100 °C) or type S (1300 °C)

- Solid state relays provide for lownoise operation

- Heating elements on support tubes provide for free radiation

- RSH: switchgear and control unit integrated in furnace housing

- RSV: switchgear and control unit separate from furnace in own wall or standing cabinet

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller B510

- Charge control with temperature measurement in the working tube

- Three-zone control for optimization of temperature uniformity

- Cooling systems for accelerated cooling of the working tube and charge

- Gas supply systems 1,15 or 2 for non-flammable protective or reactive gas operation

- Gas supply packages 3 or 4 for hydrogen operation

- Vacuum package to evacuate the working tube

- Process control and documentation via VCD software package for monitoring, documentation and contro

| Model | Tmax1 | Outer dimensions2 in mm | Max. outer tube Ø | Heated length | Length constant temperature1 +/− 5 K | Tube length | Connected load4 in kW | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in mm | in | ||||||||||||

| in °C | W3 | D | H | in mm | in mm | single zoned | three zoned | in mm | 1100 °C | 1300 °C | connection* | kg | |

| RSH 50/250/.. | 420 | 375 | 510 | 50 | 250 | 80 | – | 650 | 1.9 | 1.9 | 1-phase | 25 | |

| RSH 50/500/.. | 670 | 375 | 510 | 50 | 500 | 170 | 250 | 850 | 3.4 | 3.4 | 1-phase5 | 36 | |

| RSH 80/500/.. | 670 | 445 | 580 | 80 | 500 | 170 | 250 | 850 | 6.6 | 6.6 | 3-phase5 | 46 | |

| RSH 80/750/.. | 1100 | 920 | 495 | 630 | 80 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase5 | 76 |

| RSH 120/500/.. | or | 670 | 445 | 580 | 120 | 500 | 170 | 250 | 850 | 6.6 | 6.6 | 3-phase5 | 46 |

| RSH 120/750/.. | 1300 | 920 | 495 | 630 | 120 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase5 | 76 |

| RSH 120/1000/.. | 1170 | 495 | 630 | 120 | 1000 | 330 | 500 | 1350 | 13.7 | 13.7 | 3-phase5 | 91 | |

| RSH 170/750/.. | 920 | 495 | 630 | 170 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase5 | 76 | |

| RSH 170/1000/.. | 1170 | 495 | 630 | 170 | 1000 | 330 | 500 | 1350 | 13.7 | 13.7 | 3-phase5 | 91 | |

| RSV 50/250/.. | 545 | 590 | 975 | 50 | 250 | 80 | – | 650 | 1.9 | 1.9 | 1-phase | 25 | |

| RSV 50/500/.. | 545 | 590 | 1225 | 50 | 500 | 170 | 250 | 850 | 3.4 | 3.4 | 3-phase5 | 36 | |

| RSV 80/500/.. | 615 | 590 | 1225 | 80 | 500 | 170 | 250 | 850 | 6.6 | 6.6 | 3-phase5 | 46 | |

| RSV 80/750/.. | 1100 | 665 | 590 | 1475 | 80 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase5 | 76 |

| RSV 120/500/.. | or | 615 | 590 | 1225 | 120 | 500 | 170 | 250 | 850 | 6.6 | 6.6 | 3-phase5 | 46 |

| RSV 120/750/.. | 1300 | 665 | 590 | 1475 | 120 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase5 | 76 |

| RSV 120/1000/.. | 665 | 590 | 1725 | 120 | 1000 | 330 | 500 | 1350 | 13.7 | 13.7 | 3-phase5 | 91 | |

| RSV 170/750/.. | 665 | 590 | 1475 | 170 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase5 | 76 | |

| RSV 170/1000/.. | 665 | 590 | 1725 | 170 | 1000 | 330 | 500 | 1350 | 13.7 | 13.7 | 3-phase5 | 91 | |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K*Please see page 75 for more information about supply voltage 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 3Without tube 4At 415 volt 5At 3-phase execution an N conductor ist required (3/N/PE) | |||||||||||||

Rotary Tube Furnaces for Batch Operation up to 1100 °C

The rotary tube furnaces of the RSRB series are suited for batch operation. The rotation of the working tube ensures that the charge is in motion. Due to the shape of the quartz reactor with the tapered pipe ends the batch is kept in the rotary tube furnace and can be heat-treated an arbitrarily long time period time. A controlled heating to the temperature profiles is also possible.

Standard Equipment

- Tmax 1100 °C

- Single-zoned design

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Thermocouple type N

- Solid state relays provide for lownoise operation

- Heating elements on support tubes provide for free radiation

- Tube furnace designed as table-top model with quartz glass reactor which opens on both sides, tapered ends

- Reactor is removed for emptying out of the rotary tube furnace. Beltless drive and hinged furnace housing (opening temperature < 180 °C) provide for very easy removal through

- Adjustable drive of approx. 1-40 rpm

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller B510 (5 prgrams with each 4 segments)

- Charge control with temperature measurement in the working tube

- Three-zone control for optimization of temperature uniformity

- Reactor open on both sides, made of quartz glass with knobs for better mixing of the charge in the tube

- Gas supply package 25 for operation under non-flammable protective or reaction gases with a gas-tight rotating outlet

- Gas supply packages 3 or 4 for hydrogen operation

- Vacuum package for evacuating the working tube, depending on the pump used up to 10−2 mbar

- Left/right tilting device for easier loading and unloading of the work tube

- For filling, the furnace is tilted to the right to convey the batch into the furnace. After the heat treatment, the furnace is swiveled to the opposite side for emptying, in order to convey the product out of the reactor again. It is not necessary to remove the reactor.

- Mixing reactor made of quartz glass with integrated blade for better mixing of the batch, closed on one side, large opening on the opposite side

- Rotary tube furnace assembled on base with integrated switchgear and controller, incl. transport casters

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax1 | Outer dimensions2 in mm | Max. outer | Ø Terminal | Heated | Length constant | Tube length | Connected | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (Table-top model) | tube Ø | end | length | Temperature1 +/− 5 K in mm | load | in | |||||||

| in °C | W | D | H | in mm | in mm | in mm | single zoned | three zoned | in mm | in kW | connection* | kg | |

| RSRB 80/500/11 | 1100 | 1200 | 445 | 580 | 76 | 28 | 500 | 170 | 250 | 1140 | 6,3 | 3-phase | 100 |

| RSRB 80/750/11 | 1100 | 1450 | 495 | 630 | 76 | 28 | 750 | 250 | 375 | 1390 | 10,0 | 3-phase | 115 |

| RSRB 120/500/11 | 1100 | 1200 | 445 | 580 | 106 | 28 | 500 | 170 | 250 | 1140 | 6,3 | 3-phase | 105 |

| RSRB 120/750/11 | 1100 | 1450 | 495 | 630 | 106 | 28 | 750 | 250 | 375 | 1390 | 10,0 | 3-phase | 120 |

| RSRB 120/1000/11 | 1100 | 1700 | 495 | 630 | 106 | 28 | 1000 | 330 | 500 | 1640 | 12,9 | 3-phase | 125 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K *Please see page 75 for more information about supply voltage | |||||||||||||

Rotary Tube Furnaces for Processes with Continuous Movement up to 1300 °C

The rotary tube furnaces of the RSRC series are particularly suitable for processes in which continuously running batch material is heated short-time. These rotary furnaces can be used very flexibly for various purposes. The rotary tube furnace is slightly inclined and brought to the target temperature. The material is then fed continuously at the top of the pipe. It passes through the heated zone of the tube and falls out of the pipe at the lower end. The time of the heat treatment depends on the angle of inclination, the speed of rotation and the length of the working tube, as well as from the flow properties of the batch material. Equipped with the optionally available closed feeding system, the rotary tube furnace can also be used for processes in a defined atmosphere or in a vacuum. Depending on the process, batch and required maximum temperature, work tubes made of different materials are used.

Standard Equipment

- Tmax 1100 °C

- Working tube made of quartz glass open at both sides

- Thermocouple type N

- Tmax 1300 °C

- Open ceramic tube C 530

- Thermocouple type S

- Solid state relays provide for lownoise operation

- Heating elements on support tubes provide for free radiation

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Adjustable drive of approx. 0.5-20 rpm

- Digital display unit for the tilting angle of the rotary tube furnace

- Split-type furnace housing (opening temperature < 180 °C) provide for easy tube change

- Compact system, rotary tube furnace positioned on a base frame with

- Manual spindle drive with crank to set the tilting angle

- Switchgear and controls integrated

- Castors

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller B400 (5 prgrams with each 4 segments)

- Charge control with temperature measurement in the working tube

- Three-zone control for optimization of temperature uniformity

- Alternative work tubes for different process requirements

- Quartz glass batch reactors (Tmax 1100 °C)

- Higher temperatures up to 1500 °C available on request

- Vibrating channel on the rotary tube for convenient material supply, suitable for processes in air

- Powder discharge tube for easy material discharge, suitable for processes in air

- Feeding system for the continuous delivery of 5 liters of material under a defined atmosphere or vacuum, consisting of:

- Stainless steel funnel incl. electric vibration unit to optimize the material feeding into the working tube

- Electrically driven screw-conveyor at the inlet of the working tube with 10, 20 or 40 mm pitch and adjustable speed between 0.25 and 20 rpm

- Collecting bottle made of laboratory glass at the outlet of the working tube

- Gas supply package 26 for operation under non-flammable protective or reaction gases (only in connection with the feeding system)

- Gas supply packages 3 or 4 for hydrogen applications (only in connection with feeding system)

- Vacuum package for evacuating the working pipe, depending on the pump used up to 10−2 mbar

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax1 | Outer dimensions2 in mm | Max. outer | Heated | Length constant | Tube length | Connected | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tube Ø | length | Temperature1 +/− 5 K in mm | load | in | ||||||||

| in °C | W | D | H | in mm | in mm | single zoned | three zoned | in mm | in kW | connection* | kg | |

| RSRC 80/500/11 | 1100 | 1770 | 1050 | 1310 | 80 | 500 | 170 | 250 | 1540 | 6,7 | 3-phase | 305 |

| RSRC 80/750/11 | 1100 | 2020 | 1050 | 1360 | 80 | 750 | 250 | 375 | 1790 | 10,4 | 3-phase | 340 |

| RSRC 120/500/11 | 1100 | 1770 | 1050 | 1310 | 110 | 500 | 170 | 250 | 1540 | 6,7 | 3-phase | 305 |

| RSRC 120/750/11 | 1100 | 2020 | 1050 | 1360 | 110 | 750 | 250 | 375 | 1790 | 10,4 | 3-phase | 340 |

| RSRC 120/1000/11 | 1100 | 2270 | 1050 | 1360 | 110 | 1000 | 330 | 500 | 2040 | 13,3 | 3-phase | 350 |

| RSRC 80/500/13 | 1300 | 1170 | 1050 | 1310 | 80 | 500 | 170 | 250 | 1540 | 6,7 | 3-phase | 305 |

| RSRC 80/750/13 | 1300 | 2020 | 1050 | 1360 | 80 | 750 | 250 | 375 | 1790 | 11,7 | 3-phase | 340 |

| RSRC 120/500/13 | 1300 | 1770 | 1050 | 1310 | 110 | 500 | 170 | 250 | 1540 | 6,7 | 3-phase | 305 |

| RSRC 120/750/13 | 1300 | 2020 | 1050 | 1360 | 110 | 750 | 250 | 375 | 1790 | 11,7 | 3-phase | 340 |

| RSRC 120/1000/13 | 1300 | 2270 | 1050 | 1360 | 1360 | 1000 | 330 | 500 | 2040 | 13,3 | 3-phase | 350 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K *Please see page 75 for more information about supply voltage 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. | ||||||||||||

Tube Furnaces with Stand for Horizontal and Vertical Operation up to 1500 °C

These compact tube furnaces are used when laboratory experiments must be performed horizontally, vertically, or at specific angles. The ability to configure the angle of tilt and the working height, and their compact design, also make these tube furnaces suitable for integration into existing process systems.

Standard Equipment

- Tmax 1100 °C, 1300 °C, or 1500 °C

- Compact design

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Vertical or horizontal operation infinitely adjustable

- Angle infinitely adjustable from 0 to 90

- Working height infinitely adjustable

- Operation also possible without stand if safety guidelines are observed

- Ceramic working tube C 530 including two fiber plugs for operation under air

- Type S thermocouple

- Solid state relays provide for lownoise operation

- Heating wires wound directly around the working tube resulting in very fast heat-up rates

- Control system integrated in furnace base

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller B510 (5 programs with each 4 segments)

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Gas supply system 1 for non-flammable protective or reactive gas

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model | Tmax1 | Outer dimensions2 in mm | Inner tube Ø | Heated | Length constant | Tube length | Connected | Electrical | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | W | D | H | in mm | length in mm | temperature1 +/− 5 K in mm | in mm | load in kW | connection* | in kg | |

| RT 50/250/11 | 1100 | 350 | 380 | 740 | 50 | 250 | 80 | 360 | 1.8 | 1-phase | 25 |

| RT 50/250/13 | 1300 | 350 | 380 | 740 | 50 | 250 | 80 | 360 | 1.8 | 1-phase | 25 |

| RT 30/200/15 | 1500 | 445 | 475 | 740 | 30 | 200 | 70 | 360 | 1.8 | 1-phase | 45 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K*Please see page 75 for more information about supply voltage 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. | |||||||||||

High-Temperature Tube Furnaces with SiC Rod Heating up to 1500 °C

These compact tube furnaces with SiC rod heating and integrated switchgear with controller can be used universally for many processes. They represent an inexpensive variant in the high-temperature range. The standard mounting options for accessories make them flexible in use for a wide range of applications. The SiC heating elements arranged parallel to the working tube provide for an excellent temperature uniformity.

Standard Equipment

- Tmax 1500 °C

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Active cooling of housing for low surface temperatures

- Ceramic working tube C 799 including two fiber plugs for operation under air

- Type S thermocouple

- Solid state relays provide for lownoise operation

- SiC heating elemens, easy to replace

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller B510 (5 programs with each 4 segments)

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Charge control with temperature measurement in the working tube

- Gas supply systems 1, 2, 3 or 4

- Process control and documentation via VCD software package for monitoring, documentation and contro

| Model | Tmax3 | Outer dimensions4 in mm | Outer tube Ø | Heated length | Length constant | Tube length | Connected | Electrical | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | W | D | H | in mm | in mm | temperature3 +/− 5 K in mm | in mm | load in kW | connection* | in kg | |

| RHTC 80/230/15 | 1500 | 600 | 440 | 585 | 80 | 230 | 80 | 600 | 7.5 | 3-phase2 | 50 |

| RHTC 80/450/15 | 1500 | 820 | 440 | 585 | 80 | 450 | 150 | 830 | 11.3 | 3-phase1 | 70 |

| RHTC 80/710/15 | 1500 | 1075 | 440 | 585 | 80 | 710 | 235 | 1080 | 13.8 | 3-phase1 | 90 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K *Please see page 75 for more information about supply voltage 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 3Heating only between phase 1 and neutral 4Heating only between two phases | |||||||||||

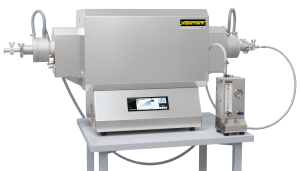

High-Temperature Tube Furnaces for Horizontal or Vertical Operation up to 1800 °C

The high-temperature tube furnaces are available in either horizontal (type RHTH) or vertical (type RHTV) designs. High-quality insulation materials made of vacuum-formed fiber plates enable energy-saving operation due to low heat storage and heat conductivity. By using different gas supply systems, operations can be performed under non-flammable or flammable protective or reactive gases or under vacuum.

Standard Equipment

- Tmax 1600 °C, 1700 °C, or 1800 °C

- Single-zoned design

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Insulation with vacuum-formed ceramic fiber plates

- Tube furnaces RHTV with frame for vertical operation

- Type B thermocouple

- Solid state relays provide for lownoise operation

- Ceramic working tube C 799 including two fiber plugs for operation under air

- Hanging and easy to change MoSi2 heating elements

- Power unit with low-voltage transformer and thyristor

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Switchgear and control unit separate from furnace in separate floor standing cabinet

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller P470 (50 programs with each 40 segments)

- Charge control with temperature measurement in the working tube

- Three-zone control for optimization of temperature uniformity (only horizontal tube furnaces RHTH)

- Gas supply system 2 for non-flammable protective or reactive gas operation

- Gas supply packages 3 or 4 for hydrogen operation

- Vacuum package to evacuate the working tube

- Process control and documentation via VCD software package for monitoring, documentation and control

| Model Horizontal design | Tmax1 | Outer dimensions3 in mm | Max. outer tube Ø | Heated length | Length constant temperature1 +/− 5 K | Tube length | Connected load | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in mm | ||||||||||||

| in °C | W2 | D | H | in mm | in mm | single zoned | three zoned | in mm | in kW | connection* | in kg | |

| RHTH 50/150/.. | 1600 or | 470 | 480 | 640 | 50 | 150 | 50 | 70 | 380 | 5.4 | 3-phase4 | 70 |

| RHTH 80/300/.. | 1700 or | 620 | 550 | 640 | 80 | 300 | 100 | 150 | 530 | 9.0 | 3-phase4 | 90 |

| RHTH 120/600/.. | 1800 | 920 | 550 | 640 | 120 | 600 | 200 | 300 | 830 | 14.4 | 3-phase4 | 110 |

| Model | Tmax1 | Outer dimensions3 in mm | Max. outer tube Ø | Heated length | Length constant temperature1 +/− 5 K | Tube length | Connected load | Electrical | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical design | in °C | W | D | H2 | in mm | in mm | in mm | in mm | in kW | connection* | in kg |

| RHTV 50/150/.. | 1600 or | 500 | 650 | 510 | 50 | 150 | 30 | 380 | 5.4 | 3-phase4 | 70 |

| RHTV 80/300/.. | 1700 or | 580 | 650 | 660 | 80 | 300 | 80 | 530 | 10.3 | 3-phase4 | 90 |

| RHTV 120/600/.. | 1800 | 580 | 650 | 960 | 120 | 600 | 170 | 830 | 19.0 | 3-phase4 | 110 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K *Please see page 75 for more information about supply voltage 2Without tube 3External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 4Heating only between two phases | |||||||||||

Customized Tube Furnaces

With their high level of flexibility and innovation, Nabertherm offers the optimal solution for customer-specific applications. Based on our standard models, we develop individual solutions also for integration in overriding process systems. The solutions shown on this page are just a few examples of delivered furnaces. From processes working under vacuum or protective gas via innovative control and automation technology for a wide selection of temperatures, sizes, lenghts and other properties of tube furnace systems – we will find the appropriate solution for a suitable process optimization.