Gas Adsorption Analyzer

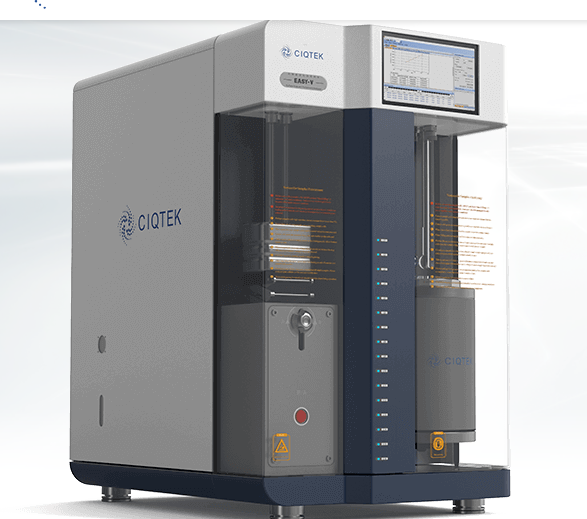

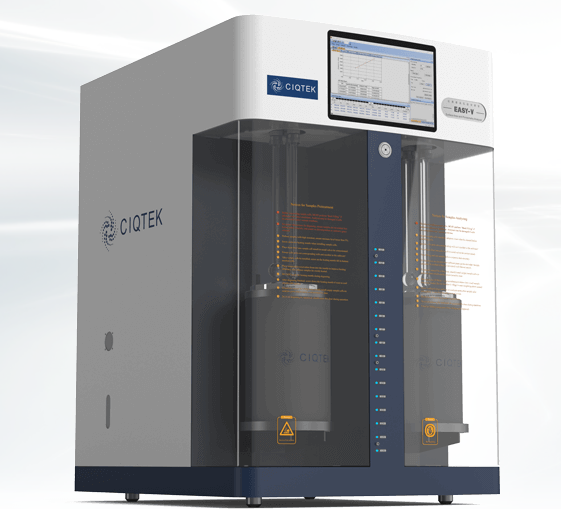

Automatic BET Surface Area & Porosimetry Analyzer EASY-V 3220 & 3210

EASY-V 3220 & 3210 are the BET specific surface area and pore size analysis instruments developed independently by CIQTEK, using the static volumetric method.

The technology obtains several international certifications and reaches the world-class level. The EASY-V series products have been delivered to multiple universities and research institutions worldwide and are well-received by our users.

▪ Specific surface area testing, range 0.0005 (m2/g) and above.

▪ Pore size analysis: 0.35 nm-2 nm (micropore), micropore size distribution analysis; 2 nm-500 nm (mesopore or macropore).

▪ Two analysis stations. EASY-V 3220: simultaneous testing of 2 samples; EASY-V 3210: alternate testing of 2 samples.

▪ Equipped with the molecular pump.

Embedded test computer, safe and stable. 10-inch capacitive touch screen, tablet control experience.

2 sample pipe joints and 1 P0 pipe joint per test module. P0 pipe can be used for specific surface area testing in a cost-effective manner.

The protective safety door can prevent safety accidents caused by accidental contact with low-temperature liquid nitrogen and eliminate the impact of environmental factors on the test.

4L stainless steel inner Dewar bottle overcomes the fragile defect of glass Dewar bottle, and high thermal insulation ensures continuous test requirements for more than 72hrs.

Test function:

Static volumetric principle, adsorption/desorption isotherms measurement, single and multi-point BET method, Langmuir method, t-plot external surface area measurement; BJH total pore volume and pore size distribution analysis, true density measurement, DR and DA filling theory, micropore analysis by HK method, micropore analysis by SF method, micropore analysis by MP method, t-plot micropore analysis; Powerful online data analysis system and specific surface area and pore size distribution test system to ensure more stable and accurate testing data.

Test ranges:

0.0005 (m2/g)~unknown upper limit (specific surface area);

0.35 nm – 500 nm, 0.0001 cc/g~unknown upper limit (total pore volume).

Test accuracy:

Specific surface area repeatability error ≤±1.0%, the most probable pore size repeatability deviation ≤ 0.02 nm.

Sample number:

EASY-V 3220: simultaneous testing of two samples; EASY-V 3210: alternate testing of two samples.

The two samples’ degassing treatment, sample testing system, and sample processing system are independent; sample testing and sample processing can be carried out simultaneously, avoiding the contamination of the test pipeline, further ensuring the accuracy of the test, and improving the service life of the instrument.

Test modes:

Integrated “Single nitrogen test mode” and “Nitrogen + helium standard test mode” for customers to choose according to their actual needs;

The “Nitrogen + helium standard test mode” in line with international standards can ensure the accuracy and consistency of results, and is easy to operate;

For samples that can adsorb helium at low temperatures, helium gas is not suitable for the determination of free space. The “Single nitrogen test mode” can get the desired test results.

Automatic BET Surface Area & Porosimetry Analyzer EASY-V 3440

EASY-V 3440 is the BET specific surface area and pore size analysis instrument developed independently by CIQTEK, using the static volumetric method.

The technology obtains several international certifications and reaches the world-class level. The CIQTEK EASY-V series products have been delivered to multiple universities and research institutions worldwide and are well-received by our users.

▪ Specific surface area testing, range 0.0005 (m2/g) and above.

▪ Pore size analysis: 0.35 nm-2 nm (micropore), micropore size distribution analysis; 2 nm-500 nm (mesopore or macropore).

▪ Four analysis stations, simultaneous testing of 4 samples.

▪ Equipped with the molecular pump.

Test function:

Static volumetric principle, adsorption/desorption isotherms measurement, single and multi-point BET method, Langmuir method, t-plot external surface area measurement; BJH total pore volume and pore size distribution analysis, DR and DA filling theory, micropore analysis by HK method, micropore analysis by SF method, micropore analysis by MP method, t-plot micropore analysis, true density measurement; Powerful online data analysis system and specific surface area and pore size distribution test system to ensure more stable and accurate test data.

Test ranges:

0.0005 (m2/g)~unknown upper limit (specific surface area);

0.35 nm – 500 nm, 0.0001 cc/g~unknown upper limit (total pore volume).

Test accuracy:

Specific surface area repeatability error ≤±1.0%, the most probable pore size repeatability deviation ≤ 0.02 nm.

Sample number:

Four samples were tested at the same time and the four samples’ degassing treatment, sample testing system, and sample processing system are independent;

Sample testing and sample processing can be carried out simultaneously, avoiding the contamination of the test pipeline, further ensuring the accuracy of the test, and improving the service life of the instrument.

Test modes:

Integrated “Single nitrogen test mode” and “Nitrogen + helium standard test mode” for customers to choose according to their actual needs;

The “Nitrogen + helium standard test mode” in line with international standards can ensure the accuracy and consistency of results, and is easy to operate;

For samples that can adsorb helium at low temperatures, helium gas is not suitable for the determination of free space. The “Single nitrogen test mode” can get the desired test results.

Automatic BET Surface Area & Porosimetry Analyzer EASY-V 1220

EASY-V 1220 is the BET specific surface area and pore size analysis instrument developed independently by CIQTEK, using the static volumetric method.

The technology obtains several international certifications and reaches the world-class level. The CIQTEK EASY-V series products have been delivered to multiple universities and research institutions worldwide and are well-received by our users.

▪ Specific surface area testing, range 0.0005 (m2/g) and above.

▪ Pore size analysis: 2 nm-500 nm.

▪ Two analysis stations, simultaneous testing of 2 samples.

▪ Equipped with the two-stage vacuum pump

4L stainless steel inner Dewar bottle overcomes the fragile defect of glass Dewar bottle, and high thermal insulation ensures continuous test requirements for more than 72hrs

Test function:

Static volumetric principle, adsorption/desorption isotherms measurement, single and multi-point BET method, Langmuir method, BJH total pore volume and pore size distribution analysis, DR and DA filling theory, t-plot external surface area measurement, true density measurement; Powerful online data analysis system and specific surface area and pore size distribution test system to ensure more stable and accurate test data.

Test ranges:

0.0005 (m2/g)~unknown upper limit (specific surface area); 2 nm – 500 nm.

Test accuracy:

Specific surface area repeatability error ≤±1.0%.

Sample number:

Two samples were tested at the same time and the two samples’ degassing treatment, sample testing system, and sample processing system are independent;

Sample testing and sample processing can be carried out simultaneously, avoiding the contamination of the test pipeline, further ensuring the accuracy of the test, and improving the service life of the instrument.

Test modes:

Integrated “Single nitrogen test mode” and “Nitrogen + helium standard test mode” for customers to choose according to their actual needs;

The “Nitrogen + helium standard test mode” in line with international standards can ensure the accuracy and consistency of results, and is easy to operate;

For samples that can adsorb helium at low temperatures, helium gas is not suitable for the determination of free space. The “Single nitrogen test mode” can get the desired test results.

Automatic BET Surface Area & Porosimetry Analyzer EASY-V 1440

EASY-V 1220 is the BET specific surface area and pore size analysis instrument developed independently by CIQTEK, using the static volumetric method.

The technology obtains several international certifications and reaches the world-class level. The CIQTEK EASY-V series products have been delivered to multiple universities and research institutions worldwide and are well-received by our users.

▪ Specific surface area testing, range 0.0005 (m2/g) and above.

▪ Pore size analysis: 2 nm-500 nm.

▪ Two analysis stations, simultaneous testing of 2 samples.

▪ Equipped with the two-stage vacuum pump

4L stainless steel inner Dewar bottle overcomes the fragile defect of glass Dewar bottle, and high thermal insulation ensures continuous test requirements for more than 72hrs

Test function:

Static volumetric principle, adsorption/desorption isotherms measurement, single and multi-point BET method, Langmuir method, BJH total pore volume and pore size distribution analysis, DR and DA filling theory, t-plot external surface area measurement, true density measurement; Powerful online data analysis system and specific surface area and pore size distribution test system to ensure more stable and accurate test data.

Test ranges:

0.0005 (m2/g)~unknown upper limit (specific surface area); 2 nm – 500 nm.

Test accuracy:

Specific surface area repeatability error ≤±1.0%.

Sample number:

Four samples were tested at the same time and the four samples’ degassing treatment (optional), sample testing system, and sample processing system are independent;

Sample testing and sample processing can be carried out simultaneously, avoiding the contamination of the test pipeline, further ensuring the accuracy of the test, and improving the service life of the instrument.

Test modes:

Integrated “Single nitrogen test mode” and “Nitrogen + helium standard test mode” for customers to choose according to their actual needs;

The “Nitrogen + helium standard test mode” in line with international standards can ensure the accuracy and consistency of results, and is easy to operate;

For samples that can adsorb helium at low temperatures, helium gas is not suitable for the determination of free space. The “Single nitrogen test mode” can get the desired test results.

Sample Degasser Introduction

Flexible heating of samples between 25°C (77°F) and 400°C (752°F) depending on the different sample processing requirements; Sample degasser can remove moisture from the sample for drying function.

During sample heating, the treatment system can be optionally evacuated to effectively remove impurities adsorbed on the surface of the sample particles and achieve a cleaner treatment of the material.

For samples that should not be in contact with air, a protective gas can be injected during the processing as needed to achieve complete isolation of the sample from the air.

After the sample treatment, the protective gas is passed into the cooling process to realize the isolation and protection of the treated sample.

For samples with more moisture and impurities on the particle surface, the protective gas can be injected by the action of airflow to achieve the function of purging the sample surface, which is conducive to the faster and more thorough removal of impurities and moisture.

Gas Pycnometer Density Analyzer EASY-G 1310

EASY-V 1220 is the BET specific surface area and pore size analysis instrument developed independently by CIQTEK, using the static volumetric method.

The technology obtains several international certifications and reaches the world-class level. The CIQTEK EASY-V series products have been delivered to multiple universities and research institutions worldwide and are well-received by our users.

▪ Specific surface area testing, range 0.0005 (m2/g) and above.

▪ Pore size analysis: 2 nm-500 nm.

▪ Two analysis stations, simultaneous testing of 2 samples.

▪ Equipped with the two-stage vacuum pump

The integrated large package module and the embedded design of the sample containers are conducive to maintaining the temperature consistency between the sample container and the gas temperature in the integrated package chamber, reducing the influence of external factors on the testing process.

Equipped with 4 sample containers of different inner diameters and capacities, which can be flexibly selected according to sample volume and characteristics; 3 sample containers are designed for more efficient and cost-effective testing.

The well-designed sample cell and other test accessories holders are convenient for small accessories storage and preservation.

The integrated design makes the whole machine compact and can be moved by one person. Meet any desktop environment.

Embedded test computer, safe and stable. The 10-inch capacitive touch screen brings a convenient control experience.

Analysis method:

Gas expansion method, volume displacement method.

Main function:

True density measurement, hard foam open/closed porosity (porosity) measurement.

Sample number:

Alternate testing of three samples with four different specifications (5mL, 10mL, 35mL, 65mL) test containers; other specifications can be customized for different material testing.

Test gas:

High purity He or N2 (purity 99.999%).

Test mode:

Positive pressure (1 Bar-2 Bar) mode for measurement; optional external vacuum pump to realize negative pressure (0-1 Bar) mode.

Test accuracy:

Test accuracy ± 0.02%, repeatability ± 0.01%, test resolution 0.0001 g/cc

Pressure accuracy:

Range 0-3 Bar, accuracy of 0.05% FS, long-term stability of 0.025% FS.

Data processing:

The high-precision PρT gas density calculation model is used to eliminate the calculation error caused by the actual gas due to the non-ideal state and improve the test accuracy.

Control system:

Programmable logic controller system with high integration and anti-interference ability improves instrument stability and service life; fully automated test mode, flexible selection of multiple test modes through software.

Test control:

Programmable embedded system, touch screen operation, USB external keyboard and mouse operation; the computer can be connected through RS232 communication mode; software can be run on an external computer for testing at the same time, integrated operation, perfect combination with computer operation methods, providing flexible options for users.

Pipeline sealing:

The integrated piping system can effectively improve the sealing system, greatly reduce the free volume space of the base chamber and improve the test accuracy; effectively improve the temperature uniformity and anti-interference the ability of the whole test system, which is conducive to improving the repeatability of test resul

High Temperature Hydrogen Storage Gas Adsorption Analyzer EASY-H 2210 & 2420

EASY-H 2210 and EASY-H 2420 high-pressure and high-temperature gas adsorption analyzer are high-performance adsorption and desorption isotherms testing instruments independently developed by CIQTEK, which adopts the static volumetric method.

EASY-H 2210 and EASY-H 2420 high-pressure and high-temperature gas adsorption analyzers are high-performance adsorption and desorption isotherms testing instruments independently developed by CIQTEK, which adopts the static volumetric method.

♦ Embedded test computer, safe and stable. 10-inch capacitive touch screen, tablet control experience.

♦ The micro-welded stainless steel sample tube and the VCR metal surface are sealed and connected to maintain a reliable sealing performance in high temperature and high pressure; high-precision test data can still be obtained for small sample loading.

♦ The protective safety door can prevent safety accidents caused by accidental contact with low-temperature liquid nitrogen and eliminate the impact of environmental factors on the test.

♦ Heating packages up to 550°C (1022°F) for ease of use; the higher temperature heating device can be equipped with a ceramic fiber integrated hard rigid heating furnace.

♦ The ball screw integrated lifting system, controlled by the stepper motor, overcomes the shortcomings of common screw types easy to jam, and so on.

♦ For EASY-H 2210: Independent 2 sample processing ports can be performed simultaneously with sample testing to improve testing efficiency.

> Test principle:

Static volumetric method

> Main functions:

Adsorption/desorption isotherms measurement at any temperature from room temperature to 550°C (1022°F), Gibbs supercritical adsorption measurement; Gas adsorption and desorption rate measurement (i.e. adsorption desorption kinetics); PCT isotherm measurement, TPD temperature programmed desorption and hydrogen discharge temperature platform measurement, hydrogen absorption and discharge pressure platform measurement, hydrogen absorption and discharge cycle experiment (fatigue test); Coal adsorption and analytical capacity measurement, adsorption and resolution rate measurement; Gas adsorption constant a and b values; Customizable coal simulation constant pressure adsorption and desorption capacity measurement function.

> Test accuracy:

Repeatability error is less than ±3%

> Test temperature:

Room temperature to 550°C (1022°F) (higher temperature can be customized); -196°C (-320.8°F) to room temperature (optional for low-temperature test function module).

> Temperature control:

The temperature control range can reach any temperature from room temperature to 550℃(1022°F), with a temperature control accuracy of 0.1℃(32.18°F);

The software integrates the temperature PID control function, which can realize the precise control of any multi-stage heating rate;

The temperature control process is set and executed automatically through the software interface, without the need for an external thermometer, which eliminates the tedious manual operation and possible misoperation of multi-stage temperature control and improves the automation of the instrument.

> Test pressure:

Continuous adsorption and desorption in the pressure range of vacuum ~ 200 Bar; The number of experimental equilibrium pressure points and pressure value can be flexibly set by software.

> Data processing:

Langmuir model regression isotherm, Langmuir maximum adsorption constant L and adsorption pressure constant B measurement (a and b values of coal adsorption); Langmuir correction model loading-ratio correlation regression (LCR) isotherm; three-parameter Langmuir regression isotherm.

> Sample numbers:

For EASY-H 2210: Two samples tested alternately and two of the analysis ports and two of the analysis ports can perform cycle test /TPD test/hydrogen absorption and desorption kinetics tests; Two Samples’ degassing treatment.

For EASY-H 2420: Four analysis ports and two of the analysis ports can perform cycle test /TPD test/hydrogen absorption and desorption kinetics tests.

> Sample tube:

Standard 10mL stainless steel micro welding sample tube. Sample tubes of other volumes can be customized upon request.

> Test gas:

High purity nitrogen, CO2 or others (Ar, Kr, H2, CH4, etc. optional)

> Pipeline structure:

316L stainless steel thick-walled pipeline, high-pressure micro-welded pipeline system, the main pipeline using micro-welding technology to seal the connection, effectively reduce the dead volume space, and improve test accuracy;

All-metal VCR connection, safe and reliable, and easy to install or remove the pipeline connection.

> Vacuum pump:

Two-stage vacuum pump, optional extended molecular pump.

> Control system:

The high-pressure pneumatic valve with a VCR interface can realize automatic on/off control within the pressure range of 200 Bar, sealability is up to 1×10-10 Pa.m3/s, service life is up to 5 million times;

The programmable logic controller system with high integration and strong anti-interference ability improves the stability and service life of the instrument.

> Protective measures:

Equipped with an external protection door, eliminates the high-temperature injury to the experimental operator. More importantly, it effectively reduces the impact of external airflow changes on the test, greatly improving the test stability and accuracy of the instrument.

> Safety measures:

The original EASY-H progressive inflation and exhausting technology can realize automatic inflation and exhausting, safe and reliable, eliminating the danger of manual operation of high-pressure gas and reducing the damage caused by large differential pressure shock to the pressure sensor.

High Temperature Hydrogen Storage Gas Adsorption Analyzer EASY-H 1210 & 1420

EASY-H 1210 and EASY-H 1420 high-pressure and high-temperature gas adsorption analyzers are high-performance adsorption and desorption isotherms testing instruments independently developed by CIQTEK, which adopts the static volumetric method.

The range of isothermal temperatures and pressures can be tested to meet the needs of many research fields. The product has a high-temperature and high-pressure adsorption testing function and a unique PCT isotherm and hydrogen absorption and desorption pressure platform, which can be widely used in rare earth alloy material hydrogen storage industry, shale gas, and coalbed methane adsorption research, petroleum exploration and gas separation and other fields; it is also important for understanding the adsorption performance of some adsorption materials such as catalysts, molecular sieves, and activated carbon, the research of fuel cells, carbon nanotubes, and graphene.

♦ Embedded test computer, safe and stable. 10-inch capacitive touch screen, tablet control experience.

♦ The micro-welded stainless steel sample tube and the VCR metal surface are sealed and connected to maintain a reliable sealing performance in high temperature and high pressure; high-precision test data can still be obtained for small sample loading.

♦ The protective safety door can prevent safety accidents caused by accidental contact with low-temperature liquid nitrogen and eliminate the impact of environmental factors on the test.

♦ Heating packages up to 550°C (1022°F) for ease of use; the higher temperature heating device can be equipped with a ceramic fiber integrated hard rigid heating furnace.

♦ The ball screw integrated lifting system, controlled by the stepper motor, overcomes the shortcomings of common screw types easy to jam, and so on.

♦ For EASY-H 1210: Independent 2 sample processing ports can be performed simultaneously with sample testing to improve testing efficiency.

> Test principle:

Static volumetric method

> Main functions:

Coal adsorption and analytical capacity measurement, adsorption and resolution rate measurement; Gas adsorption constant a and b values; Adsorption/desorption isotherms measurement at any temperature from room temperature to 550 °C (1022°F), Gibbs supercritical adsorption measurement; Gas adsorption and desorption rate measurement (i.e. adsorption-desorption kinetics); Customizable coal simulation constant pressure adsorption and desorption capacity measurement function.

> Test accuracy:

Repeatability error is less than ±3%

> Test temperature:

Room temperature to 550°C (1022°F) (higher temperature can be customized); -196°C (-320.8°F) to room temperature (optional for low-temperature test function module).

> Temperature control:

The temperature control range can reach any temperature from room temperature to 550℃(1022°F), with a temperature control accuracy of 0.1℃(32.18°F);

The software integrates the temperature PID control function, which can realize the precise control of any multi-stage heating rate;

The temperature control process is set and executed automatically through the software interface, without the need for an external thermometer, which eliminates the tedious manual operation and possible misoperation of multi-stage temperature control and improves the automation of the instrument.

> Test pressure:

Continuous adsorption and desorption in the pressure range of vacuum ~ 200 Bar; The number of experimental equilibrium pressure points and pressure value can be flexibly set by software.

> Data processing:

Langmuir model regression isotherm, Langmuir maximum adsorption constant L and adsorption pressure constant B measurement (a and b values of coal adsorption); Langmuir correction model loading-ratio correlation regression (LCR) isotherm; three-parameter Langmuir regression isotherm.

> Sample numbers:

For EASY-H 1210: two samples were tested alternately and two samples’ degassing treatment.

For EASY-H 1420: two modules were tested in parallel, and each module was tested alternately with two samples; optional sample degassing station.

> Sample tube:

10 mL 75 mm×120 mm (diameter×height) stainless steel micro welding sample tube, large capacity sample tube can place rock/coal pillar samples of 50 mm×100 mm (diameter×height);

Sample tubes of other volumes can be customized upon request.

> Test gas:

High purity nitrogen, CO2 or others (Ar, Kr, H2, CH4, etc. optional)

> Pipeline structure:

316L stainless steel thick-walled pipeline, high-pressure micro-welded pipeline system, the main pipeline using micro-welding technology to seal the connection, effectively reduce the dead volume space, and improve test accuracy;

All-metal VCR connection, safe and reliable, and easy to install or remove the pipeline connection.

> Vacuum pump:

Two-stage vacuum pump, optional extended molecular pump.

> Control system:

The high-pressure pneumatic valve with a VCR interface can realize automatic on/off control within the pressure range of 200 Bar, sealability is up to 1×10-10 Pa.m3/s, service life is up to 5 million times;

The programmable logic controller system with high integration and strong anti-interference ability improves the stability and service life of the instrument.

> Protective measures:

Equipped with an external protection door, eliminates the high-temperature injury to the experimental operator. More importantly, it effectively reduces the impact of external airflow changes on the test, greatly improving the test stability and accuracy of the instrument.

> Safety measures:

The original EASY-H progressive inflation and exhausting technology can realize automatic inflation and exhausting, safe and reliable, eliminating the danger of manual operation of high-pressure gas and reducing the damage caused by large differential pressure shock to the pressure sensor.