SH Scientific Vacuum Drying Oven

Vacuum Drying Oven

SH-VDO-08NG

– Separated vacuum port and vent port

– Du-aluminium Shelves(Excellent heat conductivity)

– Internal observation is possible through View Window

– Excellent temperature uniformity and accuracy

– Stainless Steel Internal Chamber with shelves

– Safety assurance with C.E conformity

| Model | SH-VDO-08NG |

| Temp Range | Ambient +5℃ to 250℃ (Ambient +9℉ to 482℉) |

| Time Range | 00.00 to 99HR 59MIN (MIN SEC) Selectable Digital Counter Timer |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Hot Air Jacketed |

| Temp&Time controller | Microprocess PID Membrane Touch Digital controller |

| LED Lamp | N/A |

| Heater Capa | 800 W |

Dimension Internal (W×D×H) | 200×200×200mm 7.87×7.87×7.87” |

Dimension External (W×D×H) | 385x315x555mm 15.15×12.40×21.85” |

| Weight | 29 kg |

| Capa | 8 L |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | Tempered Glass |

| Aluminium Shelves | 2 Supplied (2 Maximum) |

Electrical Requirements 120V ,50/60Hz, 1Φ | 6.6 A |

| Cat. No. | VDO08NG120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 3.5 A |

| Cat. No. | VDO08NG230 |

– View window with spring mounted shatter proof safety glass panel

– RS-485 or RS-232C interface

– Digital PID controller

– Stainless steel & Door sealing gasket

– Steel plate with powder heating coated

– Leveling feet / caster

– Safety devices

SH-VDO-30NG

– Separated vacuum port and vent port

– Du-aluminium Shelves(Excellent heat conductivity)

– Internal observation is possible through View Window

– Excellent temperature uniformity and accuracy

– Stainless Steel Internal Chamber with shelves

– Safety assurance with C.E conformity

| Model | SH-VDO-30NG |

| Temp Range | Ambient +5℃ to 250℃ (Ambient +9℉ to 482℉) |

| Time Range | 00.00 to 99HR 59MIN (MIN SEC) Selectable Digital Counter Timer |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Hot Air Jacketed |

| Temp&Time controller | Microprocess PID Membrane Touch Digital controller |

| LED Lamp | DC 24V, 1.2W, LED bar, Waterproof, Cool White |

| Heater Capa | 990 W |

Dimension Internal (W×D×H) | 300×300×300mm 11.81×11.81×11.81″ |

Dimension External (W×D×H) | 605x550x770mm 23.81×21.65×30.31” |

| Weight | 69 kg |

| Capa | 27 L |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | Tempered Glass |

| Aluminium Shelves | 2 Supplied (4 Maximum) |

Electrical Requirements 120V ,50/60Hz, 1Φ | 8.3 A |

| Cat. No. | VDO30NG120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 4.3 A |

| Cat. No. | VDO30NG230 |

– View window with spring mounted shatter proof safety glass panel

– RS-485 or RS-232C interface

– Digital PID controller

– Stainless steel & Door sealing gasket

– Steel plate with powder heating coated

– Leveling feet / caster

– Safety devices

– LED Lamp & Switch

SH-VDO-70NG

– Separated vacuum port and vent port

– Du-aluinium Shelves(Excellent heat conductivity)

– Internal observation is possible through View Window

– Excellent temperature uniformity and accuracy

– Stainless Steel Internal Chamber with shelves

– Safety assurance with C.E conformity

| Model | SH-VDO-70NG |

| Temp Range | Ambient +5℃ to 250℃ (Ambient +9℉ to 482℉) |

| Time Range | 00.00 to 99HR 59MIN (MIN SEC) Selectable Digital Counter Timer |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Hot Air Jacketed |

| Temp&Time controller | Microprocess PID Membrane Touch Digital controller |

| LED Lamp | DC 24V, 1.2W, LED bar, Waterproof, Cool White |

| Heater Capa | 1350 W |

Dimension Internal (W×D×H) | 400×400×400mm 15.75×15.75×15.75″ |

Dimension External (W×D×H) | 705x620x870mm 27.75×24.80×34.25” |

| Weight | 100 kg |

| Capa | 64 L |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | Tempered Glass |

| Aluminium Shelves | 3 Supplied (5 Maximum) |

Electrical Requirements 120V ,50/60Hz, 1Φ | 11.3 A |

| Cat. No. | VDO70NG120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 6 A |

| Cat. No. | VDO70NG230 |

– View window with spring mounted shatter proof safety glass panel

– RS-485 or RS-232C interface

– Digital PID controller

– Stainless steel & Door sealing gasket

– Steel plate with powder heating coated

– Leveling feet / caster

– Safety devices

– LED Lamp & Switch

– Stainless steel Pipe & Connector & Valve

SH-VDO-125NG

– Separated vacuum port and vent port

– Du-aluminium Shelves(Excellent heat conductivity)

– Internal observation is possible through View Window

– Excellent temperature uniformity and accuracy

– Stainless Steel Internal Chamber with shelves

– Safety assurance with C.E conformity

| Model | SH-VDO-125NG |

| Temp Range | Ambient +5℃ to 250℃ (Ambient +9℉ to 482℉) |

| Time Range | 00.00 to 99HR 59MIN (MIN SEC) Selectable Digital Counter Timer |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Hot Air Jacketed |

| Temp&Time controller | Microprocess PID Membrane Touch Digital controller |

| LED Lamp | DC 24V, 1.2W, LED bar, Waterproof, Cool White |

| Heater Capa | 3000 W |

Dimension Internal (W×D×H) | 500×500×500mm 19.69×19.69×19.69″ |

Dimension External (W×D×H) | 815x765x1050mm 32.08×30.11×41.33” |

| Weight | 200 kg |

| Capa | 125 L |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | Tempered Glass |

| Aluminium Shelves | 4 Supplied (6 Maximum) |

Electrical Requirements 120V ,50/60Hz, 1Φ | 25.0 A |

| Cat. No. | VDO125NG120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 13.0 A |

| Cat. No. | VDO125NG230 |

– View window with spring mounted shatter proof safety glass panel

– RS-485 or RS-232C interface

– Digital PID controller

– Stainless steel & Door sealing gasket

– Steel plate with powder heating coated

– Leveling feet / caster

– Safety devices

– LED Lamp & Switch

– Stainless steel Pipe & Connector & Valve

SH-VDO-216NG

– Separated vacuum port and vent port

– Du-aluminium Shelves(Excellent heat conductivity)

– Internal observation is possible through View Window

– Excellent temperature uniformity and accuracy

– Stainless Steel Internal Chamber with shelves

– Safety assurance with C.E conformity

| Model | SH-VDO-216NG |

| Temp Range | Ambient +5℃ to 250℃ (Ambient +9℉ to 482℉) |

| Time Range | 00.00 to 99HR 59MIN (MIN SEC) Selectable Digital Counter Timer |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Hot Air Jacketed |

| Temp&Time controller | Microprocess PID Membrane Touch Digital controller |

| LED Lamp | DC 24V, 1.2W, LED bar, Waterproof, Cool White |

| Heater Capa | 4500 W |

Dimension Internal (W×D×H) | 600×600×600mm 23.62×23.62×23.62″ |

Dimension External (W×D×H) | 915x880x1150mm 36.02×34.64×45.27” |

| Weight | 281 kg |

| Capa | 216 L |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | Tempered Glass |

| Aluminium Shelves | 5 Supplied (7 Maximum) |

Electrical Requirements 120V ,50/60Hz, 1Φ | 37.5 A |

| Cat. No. | VDO216NG120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 19.6 A |

| Cat. No. | VDO216NG230 |

– View window with spring mounted shatter proof safety glass panel

– RS-485 or RS-232C interface

– Digital PID controller

– Stainless steel & Door sealing gasket

– Steel plate with powder heating coated

– Leveling feet / caster

– Safety devices

– LED Lamp & Switch

– Stainless steel Pipe & Connector & Valve

400˚C Vacuum Drying Oven

SH-VDO-30NS

– Individual temperature control for each direct heating shelf (Under Patent)

– Suitable for operating temperature up to 350˚C

– Rapid heating time up to setting temperature.

– Designed to maintain stable temperature uniformity

– Safety assurance with C.E conformity

| Model | SH-VDO-30NS |

| Temp Range | Ambient +5℃ to 400℃ (Ambient +9℉ to 752℉) |

| Time Range | 00.00 to 99HR 59MIN (MIN SEC) Selectable Digital Counter Timer |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Shelf Individual Direct Heating |

| Temp&Time controller | Microprocess PID Membrane Touch Digital controller |

| Controller | 2EA |

| Heater Capa | 1.6 KW |

Dimension Internal (W×D×H) | 300×300×300mm 11.81×11.81×11.81” |

Dimension External (W×D×H) | 800x580x565mm 31.49×22.83×22.24” |

| Weight | 87 kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | N/A |

| Heating Shelves | 2 Supplied |

Electrical Requirements 120V ,50/60Hz, 1Φ | 13.3 A |

| Cat. No. | VDO30NS120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 7.0 A |

| Cat. No. | VDO30NS230 |

– Each shelf heating control function

– Digital PID controller

– Stainless steel inner chamber & Door sealing gasket

– Steel plate with powder heating coated

– Leveling caster

– Individual Direct Heating Shelves

– Stainless steel Pipe & Connector & Valve

SH-VDO-70NS

– Individual temperature control for each direct heating shelf (Under Patent)

– Suitable for operating temperature up to 350˚C

– Rapid heating time up to setting temperature.

– Designed to maintain stable temperature uniformity

– Safety assurance with C.E conformity

| Model | SH-VDO-70NS |

| Temp Range | Ambient +5℃ to 400℃ (Ambient +9℉ to 752℉) |

| Time Range | 00.00 to 99HR 59MIN (MIN SEC) Selectable Digital Counter Timer |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Shelf Individual Direct Heating |

| Temp&Time controller | Microprocess PID Membrane Touch Digital controller |

| Controller | 3EA |

| Heater Capa | 3.0 KW |

Dimension Internal (W×D×H) | 400×400×400mm 15.75×15.75×15.75” |

Dimension External (W×D×H) | 900x680x665mm 35.43×26.77×26.18” |

| Weight | 105 kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | N/A |

| Heating Shelves | 3 Supplied |

Electrical Requirements 120V ,50/60Hz, 1Φ | 25.0 A |

| Cat. No. | VDO70NS120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 13.0 A |

| Cat. No. | VDO70NS230 |

– Each shelf heating control function

– Digital PID controller

– Stainless steel inner chamber & Door sealing gasket

– Steel plate with powder heating coated

– Leveling caster

– Individual Direct Heating Shelves

– Stainless steel Pipe & Connector & Valve

SH-VDO-125NS

– Individual temperature control for each direct heating shelf (Under Patent)

– Suitable for operating temperature up to 350˚C

– Rapid heating time up to setting temperature.

– Designed to maintain stable temperature uniformity

– Safety assurance with C.E conformity

| Model | SH-VDO-70NS |

| Temp Range | Ambient +5℃ to 400℃ (Ambient +9℉ to 752℉) |

| Time Range | 00.00 to 99HR 59MIN (MIN SEC) Selectable Digital Counter Timer |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Shelf Individual Direct Heating |

| Temp&Time controller | Microprocess PID Membrane Touch Digital controller |

| Controller | 3EA |

| Heater Capa | 3.0 KW |

Dimension Internal (W×D×H) | 400×400×400mm 15.75×15.75×15.75” |

Dimension External (W×D×H) | 900x680x665mm 35.43×26.77×26.18” |

| Weight | 105 kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | N/A |

| Heating Shelves | 3 Supplied |

Electrical Requirements 120V ,50/60Hz, 1Φ | 25.0 A |

| Cat. No. | VDO70NS120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 13.0 A |

| Cat. No. | VDO70NS230 |

– Each shelf heating control function

– Digital PID controller

– Stainless steel inner chamber & Door sealing gasket

– Steel plate with powder heating coated

– Leveling caster

– Individual Direct Heating Shelves

– Stainless steel Pipe & Connector & Valve

Precision Temp Control Vacuum Drying Oven

SH-VDO-175NG

– Individual precision temperature control for each direct heating shelf (Under Patent)

– Specialized in food industry with perfect application of precision drying process

– Rapid heating time up to setting temperature.

– Designed to maintain stable temperature uniformity

– Safety assurance with UL and CE conformity

| Model | SH-VDO-175NG |

| Temp Range | Ambient +5℃ to 150℃ (Ambient +9℉ to 302℉) |

| Temp Uniformity | ±0.5℃ at 38℃ (100℉) |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Shelf Individual Direct Heating |

| Temp&Time controller | Microprocess PID Digital controller |

| Controller | 4EA |

| Heater Capa | 0.3KW x 4EA =1.2KW |

| LED Lamp | DC 24V, 1.2W, LED bar, Waterproof, Cool White |

Dimension Internal (W×D×H) | 500×700×500mm 19.7×27.6×19.7” |

Dimension External (W×D×H) | 865x955x715mm 34.05×37.60×28.15” |

| Weight | 160 kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | YES (with LED light) |

| Heating Shelves | 4 Supplied |

Electrical Requirements 120V ,50/60Hz, 1Φ | 10 A |

| Cat. No. | VDO175NG120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 5.2 A |

| Cat. No. | VDO175NG230 |

SH-VDO-252NG

– Individual precision temperature control for each direct heating shelf (Under Patent)

– Specialized in food industry with perfect application of precision drying process

– Rapid heating time up to setting temperature.

– Designed to maintain stable temperature uniformity

– Safety assurance with UL and CE conformity

| Model | SH-VDO-252NG |

| Temp Range | Ambient +5℃ to 150℃ (Ambient +9℉ to 302℉) |

| Temp Uniformity | ±0.5℃ at 38℃ (100℉) |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | Shelf Individual Direct Heating |

| Temp&Time controller | Microprocess PID Digital controller |

| Controller | 5EA |

| Heater Capa | 0.3KW x 5EA =1.5KW |

| LED Lamp | DC 24V, 1.2W, LED bar, Waterproof, Cool White |

Dimension Internal (W×D×H) | 600×700×600mm 23.6×27.6×23.6” |

Dimension External (W×D×H) | 965x953x825mm 38.0×37.5×32.5” |

| Weight | 250 kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | YES (with LED light) |

| Heating Shelves | 5 Supplied |

Electrical Requirements 120V ,50/60Hz, 1Φ | 12.5 A |

| Cat. No. | VDO252NG120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 6.5 A |

| Cat. No. | VDO252NG230 |

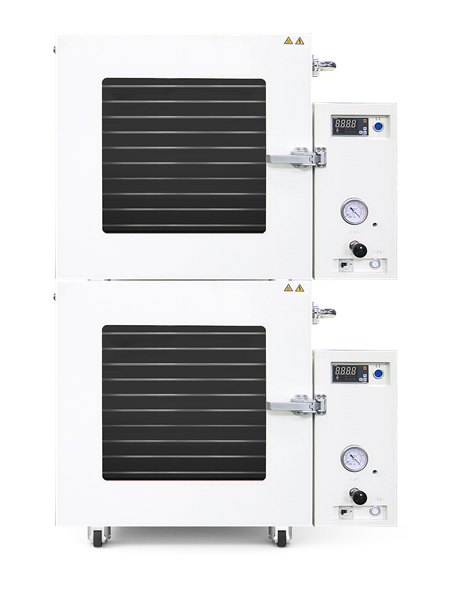

SH-VOD-2

– 5 sided wall heating

– Specialized in food industry with perfect application of precision drying process

– Wide shelves space

– Designed to maintain stable temperature uniformity

– Safety assurance with UL and CE conformity

| Model | SH-VDO-96NG |

| Temp Range | Ambient +5℃ to 150℃ (Ambient +9℉ to 302℉) |

| Temp Uniformity | ±0.5℃ at 38℃ (100℉) |

Vacuum Resistance | 0 to 76 cmHg (0 to 0.1MPa) |

| Heating Type | 5 sided wall heating |

| Temp&Time controller | Microprocess PID Digital controller |

| Controller | 10EA |

| Heater Capa | 1.5kW |

| LED Lamp | DC 24V, 1.2W, LED bar, Waterproof, Cool White |

Dimension Internal (W×D×H) | 400×600×400mm |

Dimension External (W×D×H) | 880x820x720mm |

| Weight | 116 kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Materal Packing | Silicon Rubber Packing |

| View Window | YES (with LED light) |

| Heating Shelves | 10 Supplied |

Electrical Requirements 120V ,50/60Hz, 1Φ | 12 A |

| Cat. No. | VDO96NG120 |

Electrical Requirements 230V,50/60Hz, 1Φ | 6 A |

| Cat. No. | VDO96NG230 |

Precision Temp Control Vacuum Drying Oven Package

Sh vacuum oven package VDO pk-175g

| Package Model | VDO-PK-175G |

| Vacuum Drying Oven | SH-VDO-175NG |

| Chiller | SH-WB-12CDR |

Vacuum Pump | MP 901 Z |

Dimension (W×D×H) | 1315x955x1610mm 51.77×37.60×63.38″ |

| Model | Bath Capacity |

| SH-WB-12CDR | 12.5L |

| Temp Range | Ambient -60˚C to Ambient (Low limit -40˚C) Ambient -28˚F to Ambient |

| Model | Pump Speed |

| MP 901 Z | 125L/min |

| Ultimate Pressure | < 8 torr |

Sh vacuum oven package VDO pk-252g

| Package Model | VDO-PK-252G |

| Vacuum Drying Oven | SH-VDO-252NG |

| Chiller | SH-WB-12CDR |

Vacuum Pump | MP 1801 Z |

Dimension (W×D×H) | 1415x953x1720mm 55.70×37.52×67.71″ |

| Model | Bath Capacity |

| SH-WB-12CDR | 12.5L |

| Temp Range | Ambient -60˚C to Ambient (Low limit -40˚C) Ambient -28˚F to Ambient |

| Model | Pump Speed |

| MP 1801 Z | 221.7L/min |

| Ultimate Pressure | < 8 torr |

Cold Trap Bath

SH Cold Trap Bath SH-WB-5GDR(-40℃)

– Digital temp controller type (convenient to check the temperature status)

– 3 Glass Trap installation

– Upside opended Glass Trap

– Seamless structure bath to prevent leakage of anti-freeze

– Easy internal observation with Transparent Cover

| Model | SH-WB-5GDR |

| Order Number | SH-WB-5GDR(-40) |

| Temp Controller | Microprocessor Digital controller |

Temp Control Range | Ambient -60℃ ~ -20℃ (-108℉ ~ -40℉ ) (Low limit -40℃) |

Dimension Internal (Φ×H) | 180Φ×210Hmm 7.09Φx8.27” |

Dimension External (WxD×H) | 465x560x710mm 18.18×22.04×27.95” |

| Weight | 48 kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Trap | Openable Glass Trap x3ea |

| Power | 120V ,60Hz, 1Φ |

| Cat. No. | WB5GDR-40120-60 |

Power | 230V,60Hz, 1Φ |

| Cat. No. | WB5GDR-40230-60 |

In vacuum applications, a cold trap is a device that condenses all vapors(except the permanent gases) into a liquid or solid. The main purpose is to prevent vapors being produced by an experiment from entering then vacuum pump where thy would condense and contaminate it. Cold traps can also cool surfaces or baffles to prevent oil vapors flowing from a pump into a chamber.

In such a case, a baffle or section of pipe containing a number of cooled vanes, will be attached to the inlet of an existing pumping system.

– Digital controller

– Openable 3 glass trap

– Rust-free stainless coil

– Openable glass trap

SH Cold Trap Bath SH-WB-5GDR(-80℃)

– Digital temp controller type (convenient to check the teperature status)

– 3 Glass Trap installation

– Upside opended Glass Trap

– Seamless structure bath to prevent leakage of anti-freeze

– Easy internal observation with Transparent Cover

| Model | SH-WB-5GDR |

| Order Number | SH-WB-5GDR(-80) |

| Temp Controller | Microprocessor Digital controller |

Temp Control Range | Ambient -100℃ ~ -60℃ (-180℉ ~ -76℉ ) (Low limit -80℃) |

Dimension Internal (Φ×H) | 180Φ×210Hmm 7.09Φx8.27” |

Dimension External (WxD×H) | 505x620x750mm 19.88×24.41×29.52” |

| Weight | 75 kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Trap | Openable Glass Trap x3ea |

| Power | 120V ,60Hz, 1Φ |

| Cat. No. | WB5GDR-80120-60 |

Power | 230V,60Hz, 1Φ |

| Cat. No. | WB5GDR-80230-60 |

In vacuum applications, a cold trap is a device that condenses all vapors(except the permanent gases) into a liquid or solid. The main purpose is to prevent vapors being produced by an experiment from entering then vacuum pump where thy would condense and contaminate it. Cold traps can also cool surfaces or baffles to prevent oil vapors flowing from a pump into a chamber.

In such a case, a baffle or section of pipe containing a number of cooled vanes, will be attached to the inlet of an existing pumping system.

– Digital controller

– Openable 3 glass trap

– Rust-free stainless coil

– Openable glass trap

Vacuum Oven Package

SH Vacuum Oven Package VDO-PK-G1

| Package Model | VDO-PK-G1 |

| Vacuum Drying Oven | SH-VDO-30NG |

| Cold Trap | SH-WB-5GDR(-40) |

Vacuum Pump | SH-V10 |

Dimension (W×D×H) | 1195x685x1560mm 47.04×26.96×61.41′ |

SH Vacuum Oven Package VDO-PK-G2

| Package Model | VDO-PK-G2 |

| Vacuum Drying Oven | SH-VDO-70NG |

| Cold Trap | SH-WB-5GDR(-40) |

Vacuum Pump | SH-V10 |

Dimension (W×D×H) | 1295x735x1660mm 50.98×28.93×65.35” |

SH Vacuum Oven Package VDO-PK-G3

| Package Model | VDO-PK-G3 |

| Vacuum Drying Oven | SH-VDO-125NG |

| Cold Trap | SH-WB-5GDR(-40) |

Vacuum Pump | SH-V20 |

Dimension (W×D×H) | 1355x855x1765mm 53.34×33.66×69.49′ |

SH Vacuum Oven Package VDO-PK-G4

| Package Model | VDO-PK-G4 |

| Vacuum Drying Oven | SH-VDO-216NG |

| Cold Trap | SH-WB-5GDR(-40) |

Vacuum Pump | SH-V20 |

Dimension (W×D×H) | 1455x955x1865mm 57.28×37.59×73.42′ |

SH Vacuum Oven Package VDO-PK-S1

| Package Model | VDO-PK-S1 |

| Vacuum Drying Oven | SH-VDO-30NS |

| Cold Trap | SH-WB-5GDR(-40) |

Vacuum Pump | SH-V10 |

Dimension (W×D×H) | 1380x685x1280mm 54.33×26.97×30.39″ |

ellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SH Vacuum Oven Package VDO-PK-S2

| Package Model | VDO-PK-S2 |

| Vacuum Drying Oven | SH-VDO-70NS |

| Cold Trap | SH-WB-5GDR(-40) |

Vacuum Pump | SH-V10 |

Dimension (W×D×H) | 1465x765x1450mm 57.68×30.11×57.09″ |

SH Vacuum Oven Package VDO-PK-S3

| Package Model | VDO-PK-S3 |

| Vacuum Drying Oven | SH-VDO-125NS |

| Cold Trap | SH-WB-5GDR(-40) |

Vacuum Pump | SH-V20 |

Dimension (W×D×H) | 1565x895x1535mm 61.61×35.24×60.43″ |

Vacuum Pump

SH-Vacuum Pump SH-V10

Constantly pursuing on highest technology norms, SH Scientific V series vacuum pump reached new highest level: cylinder structure and innovative oil circulation system results in super stability: auto anti-sucking back valve and two shifts gas ballast makes best reliability: Perfect combination of technology and aesthetics helps to become classic.

• Tow-Shift adjustable gas ballast valve satis-fies different requirements of condensable vapor(such as water vapor) to be exhausted out of pump in different processes.

• Dual protection of oil anti-sucking back ensures vacuum system from oil pollution when pump stops running and needs to be easily restarted.

• Forced oil circulation system consisted of oil pump and constant pressure oil supply mechanism ensures stable running of the pump.

• Less components are used, easy to maintain and repair.

Model | SH-V10 |

Pumping Speed(50/60Hz) | 78L/min |

Ultimate total pressure gas ballast close | 5×102 Pa (3.7×104 torr) |

Ultimate total pressure gas ballast open | 3 Pa (2.2×102 torr) |

Power supply | 220V,50/60Hz or 110V,50/60Hz |

Power rating(kw) | 0.4(1 Phase) |

Inlet/Exhaust Flange | KF 16/25 |

Oil capacity (L) | 0.6-1.0 |

Ambient temperature(C) | 5-40 |

Noise level(dB) | <56 |

Weight(kg) | 19 |

Recommended for | Vacuum Drying Ovens (SH-VDO-08NG, SH-VDO-BONG, SH-VDO-70NG, SH-VDO-30NS, SH-VDO-70NS) Tube Furnace All Packages |

SH-Vacuum Pump SH-V20

Constantly pursuing on highest technology norms, SH Scientific V series vacuum pump reached new highest level: cylinder structure and innovative oil circulation system results in super stability: auto anti-sucking back valve and two shifts gas ballast makes best reliability: Perfect combination of technology and aesthetics helps to become classic.

• Tow-Shift adjustable gas ballast valve satis-fies different requirements of condensable vapor(such as water vapor) to be exhausted out of pump in different processes.

• Dual protection of oil anti-sucking back ensures vacuum system from oil pollution when pump stops running and needs to be easily restarted.

• Forced oil circulation system consisted of oil pump and constant pressure oil supply mechanism ensures stable running of the pump.

• Less components are used, easy to maintain and repair.

Model | SH-V20 |

Pumping Speed(50/60Hz) | 156L/min |

Ultimate total pressure gas ballast close | 5×102 Pa (3.7×104 torr) |

Ultimate total pressure gas ballast open | 3 Pa (2.2×102 torr) |

Power supply | 220V,50/60Hz or 110V,50/60Hz |

Power rating(kw) | 0.4(1 Phase) |

Inlet/Exhaust Flange | KF 16/25 |

Oil capacity (L) | 0.6-1.0 |

Ambient temperature(C) | 5-40 |

Noise level(dB) | <56 |

Weight(kg) | 21 |

Recommended for | Vacuum Drying Ovens (SH-VDO-70NG, SH-VDO-125NG, SH-VDO-216NG, SH-VDO-30NS, SH-VDO-70NS) Tube Furnace All Packages |

SH-Vacuum Pump SH-V40

Constantly pursuing on highest technology norms, SH Scientific V series vacuum pump reached new highest level: cylinder structure and innovative oil circulation system results in super stability: auto anti-sucking back valve and two shifts gas ballast makes best reliability: Perfect combination of technology and aesthetics helps to become classic.

• Tow-Shift adjustable gas ballast valve satis-fies different requirements of condensable vapor(such as water vapor) to be exhausted out of pump in different processes.

• Dual protection of oil anti-sucking back ensures vacuum system from oil pollution when pump stops running and needs to be easily restarted.

• Forced oil circulation system consisted of oil pump and constant pressure oil supply mechanism ensures stable running of the pump.

• Less components are used, easy to maintain and repair.

Model | SH-V40 |

Pumping Speed(50/60Hz) | 312L/min |

Ultimate total pressure gas ballast close | 4×102 Pa (3.0×10-2 torr) |

Ultimate total pressure gas ballast open | 8×10-1 Pa (6×10-3 torr) |

Power supply | 220V,50/60Hz or 110V,50/60Hz |

Power rating(kw) | 0.75(1 Phase) |

Inlet/Exhaust Flange | KF 25 |

Oil capacity (L) | 0.9-1.5 |

Ambient temperature(C) | 5-40 |

Noise level(dB) | <58 |

Weight(kg) | 30 |

Recommended for | Vacuum Drying Ovens (SH-VDO-125NG, SH-VDO-216NG, SH-VDO-125NS) |

SH-Vacuum Pump SH-V60

Constantly pursuing on highest technology norms, SH Scientific V series vacuum pump reached new highest level: cylinder structure and innovative oil circulation system results in super stability: auto anti-sucking back valve and two shifts gas ballast makes best reliability: Perfect combination of technology and aesthetics helps to become classic.

• Tow-Shift adjustable gas ballast valve satis-fies different requirements of condensable vapor(such as water vapor) to be exhausted out of pump in different processes.

• Dual protection of oil anti-sucking back ensures vacuum system from oil pollution when pump stops running and needs to be easily restarted.

• Forced oil circulation system consisted of oil pump and constant pressure oil supply mechanism ensures stable running of the pump.

• Less components are used, easy to maintain and repair.

SH-Vacuum Pump SH-VDC7

Constantly pursuing on highest technology norms, SH Scientific V series vacuum pump reached new highest level: cylinder structure and innovative oil circulation system results in super stability: auto anti-sucking back valve and two shifts gas ballast makes best reliability: Perfect combination of technology and aesthetics helps to become classic.

• Tow-Shift adjustable gas ballast valve satis-fies different requirements of condensable vapor(such as water vapor) to be exhausted out of pump in different processes.

• Dual protection of oil anti-sucking back ensures vacuum system from oil pollution when pump stops running and needs to be easily restarted.

• Forced oil circulation system consisted of oil pump and constant pressure oil supply mechanism ensures stable running of the pump.

• Less components are used, easy to maintain and repair.

Model | SH-VDC7 |

Pumping Speed(50/60Hz) | 66L/min |

Ultimate total pressure gas ballast close | 5×102 Pa (3.7×10-2 torr) |

Ultimate total pressure gas ballast open | 10 Pa (7.5×102 torr) |

Power supply | 220V,50/60Hz or 110V,50/60Hz |

Power rating(kw) | 0.37(1 Phase) |

Inlet/Exhaust Flange | KF 16/25 |

Oil capacity (L) | 0.6-1.0 |

Ambient temperature(C) | 5-40 |

Noise level(dB) | <48 |

Weight(kg) | 14.5 |

Recommended for | Vacuum Drying Ovens (SH-VDO-08NG, SH-VDO-BONG, SH-VDO-70NG, SH-VDO-30NS, SH-VDO-70NS) Tube Furnace All Packages |

SH-Vacuum Pump SH-VDC10

Constantly pursuing on highest technology norms, SH Scientific V series vacuum pump reached new highest level: cylinder structure and innovative oil circulation system results in super stability: auto anti-sucking back valve and two shifts gas ballast makes best reliability: Perfect combination of technology and aesthetics helps to become classic.

• Tow-Shift adjustable gas ballast valve satis-fies different requirements of condensable vapor(such as water vapor) to be exhausted out of pump in different processes.

• Dual protection of oil anti-sucking back ensures vacuum system from oil pollution when pump stops running and needs to be easily restarted.

• Forced oil circulation system consisted of oil pump and constant pressure oil supply mechanism ensures stable running of the pump.

Model | SH-VDC10 |

Pumping Speed(50/60Hz) | 96L/min |

Ultimate total pressure gas ballast close | 5×102 Pa (3.7×10-2 torr) |

Ultimate total pressure gas ballast open | 10 Pa (7.5×102 torr) |

Power supply | 220V,50/60Hz or 110V,50/60Hz |

Power rating(kw) | 0.37(1 Phase) |

Inlet/Exhaust Flange | KF 16/25 |

Oil capacity (L) | 0.6-1.0 |

Ambient temperature(C) | 5-40 |

Noise level(dB) | <48 |

Weight(kg) | 14.5 |

Recommended for | Vacuum Drying Ovens (SH-VDO-08NG, SH-VDO-BONG, SH-VDO-70NG, SH-VDO-30NS, SH-VDO-70NS) Tube Furnace All Packages |

SH-Vacuum Pump SH-VDC20

Constantly pursuing on highest technology norms, SH Scientific V series vacuum pump reached new highest level: cylinder structure and innovative oil circulation system results in super stability: auto anti-sucking back valve and two shifts gas ballast makes best reliability: Perfect combination of technology and aesthetics helps to become classic.

• Tow-Shift adjustable gas ballast valve satis-fies different requirements of condensable vapor(such as water vapor) to be exhausted out of pump in different processes.

• Dual protection of oil anti-sucking back ensures vacuum system from oil pollution when pump stops running and needs to be easily restarted.

• Forced oil circulation system consisted of oil pump and constant pressure oil supply mechanism ensures stable running of the p

Model | SH-VDC20 |

Pumping Speed(50/60Hz) | 183L/min |

Ultimate total pressure gas ballast close | 5×102 Pa (3.7×10-2 torr) |

Ultimate total pressure gas ballast open | 10 Pa (7.5×102 torr) |

Power supply | 220V,50/60Hz or 110V,50/60Hz |

Power rating(kw) | 0.37(1 Phase) |

Inlet/Exhaust Flange | KF 16/25 |

Oil capacity (L) | 0.6-1.0 |

Ambient temperature(C) | 5-40 |

Noise level(dB) | <50 |

Weight(kg) | 15.5 |

Recommended for | Vacuum Drying Ovens (SH-VDO-08NG, SH-VDO-BONG, SH-VDO-70NG, SH-VDO-30NS, SH-VDO-70NS) Tube Furnace All Packages |

SH-Vacuum Pump SH-DV75

- Wide product line up

- No oil back diffusion or exhaust can be repeatedly continuous operated between atmospheric and vacuum

- Low vibration, low noise and high efficiency

- Ease of maintenance

Model | SH-DV75 |

Pumping Speed(50/60Hz) | 72L/min |

Ultimate pressure | 7.9 Pa (≤6.9×10-2 torr) |

Inlet/Exhaust Flange | KF 25/16 |

Motor 1 Phase(Voltage(VAC)) | 220V,50/60Hz or 110V,50/60Hz |

Motor power | 0.25 |

Speed (rpm) | 50Hz/1425;60Hz/1725 |

Ambient Temperature | 5-40 |

Ambient temperature(C) | 5-40 |

Noise level(dB) | ≤50 |

Net Weight(kg) 1 Phase 3 Phase | 15 – |

Recommended for | Vacuum Drying Ovens (SH-VDO-08NG, SH-VDO-3ONG, SH-VDO-70NG, Tube Furnace All Packages |

SH-Vacuum Pump SH-DV150

- Wide product line up

- No oil back diffusion or exhaust can be repeatedly continuous operated between atmospheric and vacuum

- Low vibration, low noise and high efficiency

- Ease of maintenance

Model | SH-DV150 |

Pumping Speed(50/60Hz) | 143L/min |

Ultimate pressure | 5.3 Pa (≤4.0×10-2 torr) |

Inlet/Exhaust Flange | KF 25/16 |

Motor 1 Phase(Voltage(VAC)) | 220V,50/60Hz or 110V,50/60Hz |

Motor power | 0.25 |

Speed (rpm) | 50Hz/1425;60Hz/1725 |

Ambient Temperature | – |

Ambient temperature(C) | – |

Noise level(dB) | ≤57 |

Net Weight(kg) 1 Phase 3 Phase | 18 20 |

Recommended for | Vacuum Drying Ovens (SH-VDO-08NG, SH-VDO-3ONG, SH-VDO-70NG, Tube Furnace All Packages |

SH-Vacuum Pump SH-DV300

- Wide product line up

- No oil back diffusion or exhaust can be repeatedly continuous operated between atmospheric and vacuum

- Low vibration, low noise and high efficiency

Model | SH-DV300 |

Pumping Speed(50/60Hz) | 305L/min |

Ultimate pressure | 2.5Pa (≤1.9×10-2 torr) |

Inlet/Exhaust Flange | KF 25/16 |

Motor 1 Phase(Voltage(VAC)) | 220V,50/60Hz or 110V,50/60Hz |

Motor power | 0.75 |

Speed (rpm) | 50Hz/1425;60Hz/1725 |

Ambient Temperature | 5-40 |

Ambient temperature(C) | 5-40 |

Noise level(dB) | ≤60 |

Net Weight(kg) 1 Phase 3 Phase | 27 31 |

Recommended for | Vacuum Drying Ovens (SH-VDO-125NG, SH-VDO-216NG, SH-VDO-175NG, SH-VDO-252NG, SH-VDO-125NS, Tube Furnace All Packages |

SH-Vacuum Pump SH-DV600

- Wide product line up

- No oil back diffusion or exhaust can be repeatedly continuous operated between atmospheric and vacuum

- Low vibration, low noise and high efficiency

Model | SH-DV600 |

Pumping Speed(50/60Hz) | 623L/min |

Ultimate pressure | 0.9Pa (≤7.5×10-2 torr) |

Inlet/Exhaust Flange | KF 40/16 |

Motor 1 Phase(Voltage(VAC)) | 220V,50/60Hz or 110V,50/60Hz |

Motor power | 0.75 |

Speed (rpm) | 50Hz/1425;60Hz/1725 |

| Others | With Air flush |

Ambient temperature(C) | 5-40 |

Noise level(dB) | ≤61 |

Net Weight(kg) 1 Phase 3 Phase | 31 38 |

Recommended for | Vacuum Drying Ovens (SH-VDO-125NG, SH-VDO-216NG, SH-VDO-175NG, SH-VDO-252NG, SH-VDO-125NS, Tube Furnace All Packages |

SH Vacuum Drying Oven SH-VDO-96NG Vacuum oven 96iters (3.4 cu ft) with 10 shelves

Precision Temp Control Vacuum Drying Oven

– 5 sided wall heating

– Specialized in food industry with perfect application of precision drying process

– Wide shelves space

– Designed to maintain stable temperature uniformity

– Safety assurance with UL and CE conformity

SH Cold Trap Bath SH-WB-5GDR(-20℃)-40 Celsius Degree Cold Trap Bath

- Safety Device

- -Automatic reset function incoming power cut

- -Electric leakage circuit breaker

- • Option

- -Stainless steel trap

| Model | SH-WB-5GDR |

|---|---|

| Order Number | SH-WB-5GDR(-20) |

| Temp Controller | Microprocessor digital controller |

| Temp Control Range | Ambient -40℃ ~ ambient (-40℉ ~ ambient) (Low limit -20℃) |

| Dimension Internal (W×D×H) | 200x200x130mm 7.87×7.87×5.12″ |

| Dimension External (W×D×H) | 283x400x455mm 11.14×15.75×17.91” |

| Weight | 26.5kg |

| Material Internal | Stainless Steel |

| Material External | Steel Plate With Powder Heating Coated |

| Trap | Openable glass trap×3EA |

| Noise (dB) | 53 |

| Power | 230V, 60Hz, 1Φ |

| Cat. No. | WB5GDR-20230-60 |