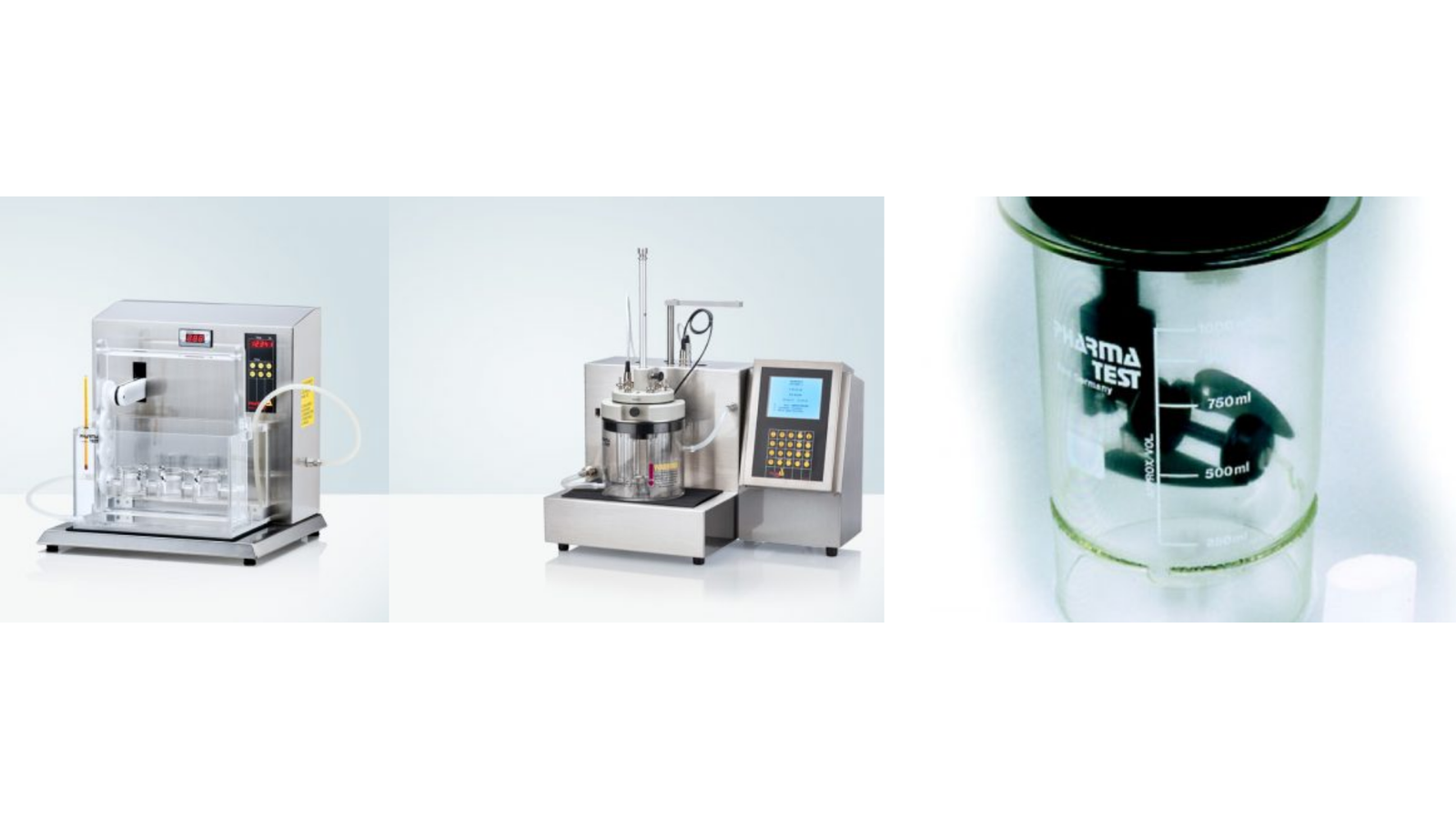

- Tablet Dissolution Testing Instruments

- Offline Automated Dissolution Systems

- Online Automated Dissolution Systems

- In-Situ Dissolution Testing (Coming Soon)

- Media Preparation

- UV/VIS Spectrometers

Tablet Disintegration Testing Instruments

Tablet disintegration testing instruments are widely used in the pharmaceutical industry to evaluate the disintegration characteristics of formulations and the quality control of different dosage forms.

Suppository Testing Instruments

This range of instruments to test the quality of suppositories, pessaries and creams includes disintegration and penetration testers.

Tablet Hardness Testing Instruments

Tablet hardness testing is used to test the breaking point and structural integrity of a tablet prior to storage, transportation, and handling before usage.

Ampoule Testing Instruments

Many liquid drugs are delivered in ampoules.We offer a fully DIN/ISO 9187 compliant solution to test the hardness of empty ampoules at line during production.

Tablet Friability Testing Instruments

Friability testing is used to test the durability of tablets during packing processes and transit. This involves repeatedly dropping a sample of tablets over a fixed time, using a rotating drum with a baffle.

Powder Testing Instruments

The Pharma Test powder testing product portfolio includes instruments to not only measure bulk density but also tap density and flowability.

Leak Testing Instruments

The leak test apparatus is used in the pharmaceutical industry to check the integrity of tablet strips, blister packs and small bottles.

PT-LT

Leak Test Apparatus

The PT-LT is used to test for the integrity of packed strips, blisters and small sachets containing tablets, granulates, liquids and so on. The instrument is used to test the quality of the packaging process and to check that the seals enclosing the product are perfectly intact. The PT-LT leak tester is designed to find the smallest holes and imperfections in blister packs and other semi-rigid product packaging. It is designed in compliance to the USP monograph <1136>.

>Test the integrity of strips, blisters and bottles

>Large 16 x 2cm LCD shows vacuum and electronic countdown timer

>Enter all test parameters such as date, time, user ID and sample ID

>Set vacuum and trip vacuum can be set via the keypad

>Built-in rugged, oil-free vacuum pump

>Automatic slow vacuum release from the desiccators

>Printer port for parallel dot-matrix printers

>Automated print-out of test report

Advantages

>Ensure the quality of your packaging process

>Easy operation by programmed sequence

>Fully automated microprocessor controlled equipment

>Stainless steel housing to fit well into a production area

>IQ/OQ documents included free of charge

| Parameter | Specification |

| Vacuum Level | > 650mmHg |

| Vacuum Setting | Vacuum can stabilize for a set value from: » Less than 400mmHg: ± 10mmHg within 30 seconds » Above 400mmHg: ± 5mmHg within 30 seconds |

| Display | Large 160 x 20 mm LCD |

| Data Entry | Function key |

| Timer | Can be set from 1 to 99 minutes |

| Desiccator Sizes | 380mm, 250mm, 200mm or 150mm Ø (optional) |

| Printer | Parallel port for dot-matrix printers |

| Power | Nominal 220 – 240V or 110 – 120V |

| Instrument dimensions | Approx. 360 x 250 x 240 mm (Length x Width x Height) |

| Net weight | Approx. 14.5 kg |

| Certification | All components certified to USP / EP requirements |

| CE / EMC Certification | All CE / EMC Certification provided |

| Validation | All IQ & OQ documents included |

Included in the Standard Scope of Supply

>PT-LT instrument with built-in vacuum pump

>Comprehensive documentation folder including:

>User manual

>QC/DQ testing certificate

>IQ documentation

>OQ documentation

>Conformity Declaration

>CE/EMC Declaration

>Instrument logbook

Leak Testing Instruments