FURNACE

SH-FU-3MGE Muffle Furnace Economic 1050 Celsius (3L)

1050℃ economic muffle furnace (3L)

Economic muffle furnace with flap door

– General laboratory use and ashing process

– Recommended ideal running temperature is below 850℃

– Heating from 3 sides

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Single housing

– Ceramic fiber materials which are not classified as carcinogenic

– Light weight

– Prompt heat up and good maintaining

– SSR operation and PID control provides low noise operation and precise temp control (+/-1℃)

| Model | SH-FU-3MGE |

| Max temperature | 1050℃ |

| Continuous running temperature | 850℃ |

Chamber volume | 3liters |

| Controller | Digital PID controller |

| Sensor | K type |

| Heater | 1.1kW |

| Heating element | KANTAL A-1 with ceramic fiber |

Insulation | Ceramic |

Power supply | 110V, 50/60Hz, 1p, 10A 220V, 50/60Hz, 1p, 5A |

| Net weight | 19kg |

| Chamber size | 130x220x110mm |

| External size | 300x380x410mm |

SH-FU-5MGE Muffle Furnace Economic 1050 Celsius (5L)

1050℃ economic muffle furnace (5L)

– Economic muffle furnace with flap door

– General laboratory use and ashing process

– Recommended ideal running temperature is below 850℃

– Heating from 3 sides

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Single housing

– Ceramic fiber materials which are not classified as carcinogenic

– Light weight

– Prompt heat up and good maintaining

– SSR operation and PID control provides low noise operation and precise temp control (+/-1℃)

| Model | SH-FU-5MGE |

| Max temperature | 1050℃ |

| Continuous running temperature | 850℃ |

Chamber volume | 5liters |

| Controller | Digital PID controller |

| Sensor | K type |

| Heater | 1.5kW |

| Heating element | KANTAL A-1 with ceramic fiber |

Insulation | Ceramic |

Power supply | 110V, 50/60Hz, 1p, 14A 220V, 50/60Hz, 1p, 7A |

| Net weight | 22kg |

| Chamber size | 150x260x130mm |

| External size | 320x430x430mm |

SH-FU-7MGE Muffle Furnace Economic 1050 Celsius (7L)

1050℃ economic muffle furnace (7L)

– Economic muffle furnace with flap door

– General laboratory use and ashing process

– Recommended ideal running temperature is below 850℃

– Heating from 3 sides

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Single housing

– Ceramic fiber materials which are not classified as carcinogenic

– Light weight

– Prompt heat up and good maintaining

– SSR operation and PID control provides low noise operation and precise temp control (+/-1℃)

| Model | SH-FU-7MGE |

| Max temperature | 1050℃ |

| Continuous running temperature | 850℃ |

Chamber volume | 7liters |

| Controller | Digital PID controller |

| Sensor | K type |

| Heater | 2.0kW |

| Heating element | KANTAL A-1 with ceramic fiber |

Insulation | Ceramic |

Power supply | 110V, 50/60Hz, 1p, 18A 220V, 50/60Hz, 1p, 9A |

| Net weight | 28kg |

| Chamber size | 170x290x150mm |

| External size | 340x460x450mm |

SH-FU-11MGE Muffle Furnace Economic 1050 Celsius (11L)

1050℃ economic muffle furnace (11L)

– Economic muffle furnace with flap door

– General laboratory use and ashing process

– Recommended ideal running temperature is below 850℃

– Heating from 3 sides

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Single housing

– Ceramic fiber materials which are not classified as carcinogenic

– Light weight

– Prompt heat up and good maintaining

– SSR operation and PID control provides low noise operation and precise temp control (+/-1℃)

| Model | SH-FU-11MGE |

| Max temperature | 1050℃ |

| Continuous running temperature | 850℃ |

Chamber volume | 7liters |

| Controller | Digital PID controller |

| Sensor | K type |

| Heater | 2.8kW |

| Heating element | KANTAL A-1 with ceramic fiber |

Insulation | Ceramic |

Power supply | 110V, 50/60Hz, 1p, 25A 220V, 50/60Hz, 1p, 13A |

| Net weight | 34kg |

| Chamber size | 200x310x180mm |

| External size | 370x470x480mm |

SH-FU-3MG Muffle Furnace General 1200 Celsius (3L)

1200℃ general muffle furnace (3L)

– General muffle furnace with swing door

– General laboratory use and ashing

– Recommended ideal running temperature is below 1000℃

– Heating from 4 sides and excellent temperature uniformity (+/-2.5%)

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature (29~30℃ at 800℃)

– Ceramic fiber materials which are not classified as carcinogenic

– Light weight

– Prompt heat up and good maintaining

– SSR operation and PID control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

| Model | SH-FU-3MG |

| Max temperature | 1200℃ |

| Continuous running temperature | 1000℃ |

Chamber volume | 3liters |

| Controller | Digital PID controller |

| Sensor | K type |

| Heater | 1.4kW |

| Heating element | KANTAL A-1 |

Insulation | Ceramic |

Power supply | 110V, 50/60Hz, 1p, 12A 220V, 50/60Hz, 1p, 6A |

| Net weight | 34kg |

| Chamber size | 130x250x90mm |

| External size | 370x510x570mm |

SH-FU-5MG Muffle Furnace General 1200 Celsius (5L)

1200℃ general muffle furnace (5L)

– General muffle furnace with swing door

– General laboratory use and ashing

– Recommended ideal running temperature is below 1000℃

– Heating from 4 sides and excellent temperature uniformity (+/-2.5%)

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature (29~30℃ at 800℃)

– Ceramic fiber materials which are not classified as carcinogenic

– Light weight

– Prompt heat up and good maintaining

– SSR operation and PID control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-5MG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Chamber volume | 5liters |

Controller | Digital PID controller |

Sensor | K type |

Heater | 1.6kW |

Heating element | KANTAL A-1 |

Insulation | Ceramic |

Power supply | 110V, 50/60Hz, 1p, 14A 220V, 50/60Hz, 1p, 7A |

Net weight | 44kg |

Chamber size | 150x300x100mm |

External size | 390x560x580mm |

SH-FU-14MG Muffle Furnace General 1200 Celsius (14L)

1200℃ general muffle furnace (14L)

– General muffle furnace with swing door

– General laboratory use and ashing

– Recommended ideal running temperature is below 1000℃

– Heating from 4 sides and excellent temperature uniformity (+/-2.5%)

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature (29~30℃ at 800℃)

– Ceramic fiber materials which are not classified as carcinogenic

– Light weight

– Prompt heat up and good maintaining

– SSR operation and PID control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-14MG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Chamber volume | 14liters |

Controller | Digital PID controller |

Sensor | K type |

Heater | 4.1kW |

Heating element | KANTAL A-1 |

Insulation | Ceramic |

Power supply | 110V, 50/60Hz, 1p, 34A 220V, 50/60Hz, 1p, 18A |

Net weight | 65kg |

Chamber size | 250x350x160mm |

External size | 500x610x670mm |

SH-FU-27MG 1200℃ general muffle furnace (27L)

1200℃ general muffle furnace (27L)

– General muffle furnace with swing door

– General laboratory use and ashing

– Recommended ideal running temperature is below 1000℃

– Heating from 4 sides and excellent temperature uniformity (+/-2.5%)

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature (29~30℃ at 800℃)

– Ceramic fiber materials which are not classified as carcinogenic

– Light weight

– Prompt heat up and good maintaining

– SSR operation and PID control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-27MG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Chamber volume | 27liters |

Controller | Programmable Controller(SP570) |

Sensor | K type |

Heater | 4.9kW |

Heating element | KANTAL A-1 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 21A 220V, 50/60Hz, 3p, 13A 380V, 50/60Hz 3p, 8A |

Net weight | 105kg |

Chamber size | 300x300x300mm |

External size | 580x590x840mm |

SH-FU-4MH 1500℃ high temp muffle furnace (4.5L)

1500℃ high temp muffle furnace (4.5L)

– High temperature furnace with SiC Rod heating with swing door

– Great for testing metallic sample

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1350℃ *24hours continuous running

– Heating from 2 sides and vertical SiC rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-4MH |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Chamber volume | 4.5liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 5kW |

Heating element | SiC |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 22A |

Net weight | 92kg |

Chamber size | 150x200x150mm |

External size | 820x560x740mm |

SH-FU-11MH 1500℃ high temp muffle furnace (11L)

1500℃ high temp muffle furnace (11L)

– High temperature furnace with SiC Rod heating with swing door

– Great for testing metallic sample

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1350℃ *24hours continuous running

– Heating from 2 sides and vertical SiC rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-11MH |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Chamber volume | 11liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 7.6kW |

Heating element | SiC |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 33A |

Net weight | 102kg |

Chamber size | 200x270x200mm |

External size | 870x630x790mm |

SH-FU-22MH 1500℃ high temp muffle furnace (22L)

1500℃ high temp muffle furnace (22L)

– High temperature furnace with SiC Rod heating with swing door

– Great for testing metallic sample

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1350℃ *24hours continuous running

– Heating from 2 sides and vertical SiC rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-22MH |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Chamber volume | 22liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 9.6kW |

Heating element | SiC |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 42A |

Net weight | 147kg |

Chamber size | 250x350x250mm |

External size | 920x710x970mm |

SH-FU-36MH 1500℃ high temp muffle furnace (36L)

1500℃ high temp muffle furnace (36L)

– High temperature furnace with SiC Rod heating with swing door

– Great for testing metallic sample

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1350℃ *24hours continuous running

– Heating from 2 sides and vertical SiC rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-36MH |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Chamber volume | 36liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 18kW |

Heating element | SiC |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 48A |

Net weight | 154kg |

Chamber size | 300x300x300mm |

External size | 970x760x920mm |

SH-FU-4MS(1700℃) High-Temperature Furnaces with MoSi2 Rod Heating up to 1700°C (4.5L)

1700℃ high temp muffle furnace (4.5L)

– High-Temperature Furnaces with MoSi2 Rod Heating up to 1700°C

– Great for testing metallic sample and sintering

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1550℃ *24hours continuous running

– Heating from 2 sides and vertical MoSi2 rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-4MS(17) |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Chamber volume | 4.5liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 4.2kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 19A |

Net weight | 150kg |

Chamber size | 150x250x150mm |

External size | 920x600x770mm |

SH-FU-11MS(1700℃) High-Temperature Furnaces with MoSi2 Rod Heating up to 1700°C (11L)

1700℃ high temp muffle furnace (11L)

– High-Temperature Furnaces with MoSi2 Rod Heating up to 1700°C

– Great for testing metallic sample and sintering

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1550℃ *24hours continuous running

– Heating from 2 sides and vertical MoSi2 rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-11MS(17) |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Chamber volume | 11liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 9.2kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 42A |

Net weight | 186kg |

Chamber size | 200x270x200mm |

External size | 1000x670x840mm |

– Gas atmosphere available with optional flow meter

SH-FU-22MS(1700℃) High-Temperature Furnaces with MoSi2 Rod Heating up to 1700°C (22L)

1700℃ high temp muffle furnace (22L)

– High-Temperature Furnaces with MoSi2 Rod Heating up to 1700°C

– Great for testing metallic sample and sintering

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1550℃ *24hours continuous running

– Heating from 2 sides and vertical MoSi2 rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-22MS(17) |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Chamber volume | 22liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 13kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 60A |

Net weight | 210kg |

Chamber size | 250x350x250mm |

External size | 1080x750x910mm |

SH-FU-4MS(1800℃) High-Temperature Furnaces with MoSi2 Rod Heating up to 1800°C (4.5L)

1800℃ high temp muffle furnace (4.5L)

– High-Temperature Furnaces with MoSi2 Rod Heating up to 1800°C

– Great for testing metallic sample and sintering

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1650℃ *24hours continuous running

– Heating from 2 sides and vertical MoSi2 rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-4MS(18) |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Chamber volume | 4.5liters |

Controller | Programmable controller |

Sensor | B type |

Heater | 3kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 14A |

Net weight | 150kg |

Chamber size | 150x250x150mm |

External size | 920x600x770mm |

SH-FU-11MS(1800℃) High-Temperature Furnaces with MoSi2 Rod Heating up to 1800°C (11L)

1800℃ high temp muffle furnace (11L)

– High-Temperature Furnaces with MoSi2 Rod Heating up to 1800°C

– Great for testing metallic sample and sintering

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1650℃ *24hours continuous running

– Heating from 2 sides and vertical MoSi2 rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-11MS(18) |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Chamber volume | 11liters |

Controller | Programmable controller |

Sensor | B type |

Heater | 6.6kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 30A |

Net weight | 186kg |

Chamber size | 200x270x200mm |

External size | 1000x670x840mm |

SH-FU-22MS(1800℃) High-Temperature Furnaces with MoSi2 Rod Heating up to 1800°C (22L)

1800℃ high temp muffle furnace (22L)

– High-Temperature Furnaces with MoSi2 Rod Heating up to 1800°C

– Great for testing metallic sample and sintering

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Recommended ideal running temperature is below 1650℃ *24hours continuous running

– Heating from 2 sides and vertical MoSi2 rod preventing warping. Easy replacement

– Excellent outgassing thanks to the exhaust air outlet on the head of chamber, i.e plastic polymer

– Double housing and low surface temperature

– Ceramic fiber materials which are not classified as carcinogenic

– Great temp uniformity (+/-4%)

– Prompt heat up and good maintaining

– SCR operation and programmable control provides low noise operation and precise temp control (+/-1℃)

– Gas atmosphere available with optional flow meter

Model | SH-FU-22MS(18) |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Chamber volume | 22liters |

Controller | Programmable controller |

Sensor | B type |

Heater | 9.5kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 44A |

Net weight | 210kg |

Chamber size | 250x350x250mm |

External size | 1080x750x910mm |

SH-FU3.5MGU 1200℃ elevator furnace (3.5L)

1200℃ high temp elevator furnace (3.5L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model

Model | SH-FU-3.5MGU |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Chamber volume | 3.5liters |

Controller | Digital PID controller |

Sensor | K type |

Heater | 2.2kW |

Heating element | KANTAL A-1 with ceramic fiber |

Insulation | Ceramic |

Power supply | 110V, 50/60Hz, 1p, 20A 220V, 50/60Hz, 1p, 10A |

Net weight | 45kg |

Chamber size | 140x140x180mm |

External size | 410x480x900mm |

SH-FU6.5MGU 1200℃ elevator furnace (6.5L)

1200℃ high temp elevator furnace (6.5L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model

Model | SH-FU-6.5MGU |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Chamber volume | 6.5liters |

Controller | Digital PID controller |

Sensor | K type |

Heater | 3kW |

Heating element | KANTAL A-1 with ceramic fiber |

Insulation | Ceramic |

Power supply | 110V, 50/60Hz, 1p, 27A 220V, 50/60Hz, 1p, 14A |

Net weight | 60kg |

Chamber size | 180x180x200mm |

External size | 450x520x920mm |

SH-FU-2MHU 1500℃ high temp elevator furnace (2.2L)

1500℃ high temp elevator furnace (2.2L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Built in programmable controller. 5 patterns and 9 segment/pattern.

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model | SH-FU-2MHU |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Chamber volume | 2.2liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 3.5kW |

Heating element | SiC |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 16A |

Net weight | 65kg |

Chamber size | 120x120x150mm |

External size | 420x520x1030mm |

SH-FU-4MHU 1500℃ high temp elevator furnace (3.8L)

1500℃ high temp elevator furnace (3.8L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Built in programmable controller. 5 patterns and 9 segment/pattern.

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model | SH-FU-4MHU |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Chamber volume | 3.8liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 5.3kW |

Heating element | SiC |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 124 |

Net weight | 80kg |

Chamber size | 150x150x170mm |

External size | 480x550x1070mm |

boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

SH-FU-6MHU 1500℃ high temp elevator furnace (6.2L)

1500℃ high temp elevator furnace (6.2L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Built in programmable controller. 5 patterns and 9 segment/pattern.

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consum

Model | SH-FU-6MHU |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Chamber volume | 6.2liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 7.7kW |

Heating element | SiC |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 35A |

Net weight | 105kg |

Chamber size | 180x180x190mm |

External size | 510x580x1120mm |

SH-FU-2MSU(1700℃) 1700℃ high temp elevator furnace (2.2L)

1700℃ high temp elevator furnace (2.2L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Built in programmable controller

– Sintering

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model | SH-FU-2MSU(17) |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Chamber volume | 2.2liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 2.7kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 12A |

Net weight | 65kg |

Chamber size | 120x120x150mm |

External size | 450x520x1030mm |

SH-FU-4MSU(1700℃) 1700℃ high temp elevator furnace (3.8L)

1700℃ high temp elevator furnace (3.8L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Built in programmable controller

– Sintering

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model | SH-FU-4MSU(17) |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Chamber volume | 3.8liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 4.5kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 20A |

Net weight80 | 80kg |

Chamber size | 150x150x170mm |

External size | 480x550x1070mm |

SH-FU-6MSU(1700℃) 1700℃ high temp elevator furnace (6.2L)

1700℃ high temp elevator furnace (6.2L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Built in programmable controller

– Sintering

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model | SH-FU-6MSU(17) |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Chamber volume | 6.2liters |

Controller | Programmable controller |

Sensor | R type |

Heater | 6.6kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 30A |

Net weight | 105kg |

Chamber size | 180x180x190mm |

External size | 510x580x1120mm |

SH-FU-2MSU(1800℃) 1800℃ high temp elevator furnace (2.2L)

1800℃ high temp elevator furnace (2.2L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Built in programmable controller

– Sintering

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model | SH-FU-2MSU(18) |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Chamber volume | 2.2liters |

Controller | Programmable controller |

Sensor | B type |

Heater | 1.8kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 8A |

Net weight | 65kg |

Chamber size | 120x120x150mm |

External size | 420x520x1030mm |

SH-FU-4MSU(1800℃) 1800℃ high temp elevator furnace (3.8L)

1800℃ high temp elevator furnace (3.8L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Built in programmable controller

– Sintering

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model | SH-FU-4MSU(18) |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Chamber volume | 3.8liters |

Controller | Programmable controller |

Sensor | B type |

Heater | 3kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 14A |

Net weight | 80kg |

Chamber size | 150x150x170mm |

External size | 480x550x1070mm |

SH-FU-100LTG(600mm Length Hot Zone)

1200℃ tube furnace (100mm diameter tube and 600mm hot zone)

– General tube furnace with hinged door

– Double housing and low surface temperature (29~30℃ at 800℃)

– Recommended ideal running temperature is below 1000℃

– Great durability thanks to Kanthal heating element

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes and heating length. 50/80/100/120mm diameter and 300/600mm heating zone

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-100LTG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Tube diameter | 100mm |

Controller | Programmable controller |

Sensor | K type |

Heater | 3.2kW |

Hot zone | 600mm |

Heating element | Kantal with ceramic molding |

Insulation | Ceramic |

External size | 810x400x560mm |

Weight | 68kg |

Power supply | 220V, 50/60Hz, 1p, 27A 220V, 50/60Hz, 3p, 15A 380V, 50/60Hz, 3p, 9A |

SH-FU-80LTG(600mm Length Hot Zone)

1200℃ tube furnace (80mm diameter tube and 600mm hot zone)

– General tube furnace with hinged door

– Double housing and low surface temperature (29~30℃ at 800℃)

– Recommended ideal running temperature is below 1000℃

– Great durability thanks to Kanthal heating element

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes and heating length. 50/80/100/120mm diameter and 300/600mm heating zone

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-80LTG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Tube diameter | 80mm |

Controller | Programmable controller |

Sensor | K type |

Heater | 2.5kW |

Hot zone | 600mm |

Heating element | Kantal with ceramic molding |

Insulation | Ceramic |

External size | 810x760x540mm |

Weight | 56kg |

Power supply | 110V, 50/60Hz, 1p, 40A 220V, 50/60Hz, 1p, 20A |

SH-FU-50LTG(600mm Length Hot Zone)

1200℃ tube furnace (50mm diameter tube and 600mm hot zone)

– General tube furnace with hinged door

– Double housing and low surface temperature (29~30℃ at 800℃)

– Recommended ideal running temperature is below 1000℃

– Great durability thanks to Kanthal heating element

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes and heating length. 50/80/100/120mm diameter and 300/600mm heating zone

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-50LTG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Tube diameter | 50mm |

Controller | Programmable controller |

Sensor | K type |

Heater | 2kW |

Hot zone | 600mm |

Heating element | Kantal with ceramic molding |

Insulation | Ceramic |

External size | 800x360x520mm |

Weight | 52kg |

Power supply | 110V, 50/60Hz, 1p, 33A 220V, 50/60Hz, 1p, 16A |

SH-FU-120STG(300mm Length Hot Zone

1200℃ tube furnace (120mm diameter tube and 300mm hot zone)

– General tube furnace with hinged door

– Double housing and low surface temperature (29~30℃ at 800℃)

– Recommended ideal running temperature is below 1000℃

– Great durability thanks to Kanthal heating element

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes and heating length. 50/80/100/120mm diameter and 300/600mm heating zone

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-120STG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Tube diameter | 120mm |

Controller | Programmable controller |

Sensor | K type |

Heater | 3.6kW |

Hot zone | 300mm |

Heating element | Kantal with ceramic molding |

Insulation | Ceramic |

External size | 500x460x630mm |

Weight | 70kg |

Power supply | 110V, 50/60Hz, 1p, 33A 220V, 50/60Hz, 1p, 16A |

SH-FU-100STG(300mm Length Hot Zone)

1200℃ tube furnace (100mm diameter tube and 300mm hot zone)

– General tube furnace with hinged door

– Double housing and low surface temperature (29~30℃ at 800℃)

– Recommended ideal running temperature is below 1000℃

– Great durability thanks to Kanthal heating element

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes and heating length. 50/80/100/120mm diameter and 300/600mm heating zone

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-100STG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Tube diameter | 100mm |

Controller | Programmable controller |

Sensor | K type |

Heater | 3.2kW |

Hot zone | 300mm |

Heating element | Kantal with ceramic molding |

Insulation | Ceramic |

External size | 500x400x560mm |

Weight | 48kg |

Power supply | 110V, 50/60Hz, 1p, 28A 220V, 50/60Hz, 1p, 15A |

SH-FU-80STG(300mm Length Hot Zone)

1200℃ tube furnace (80mm diameter tube and 300mm hot zone)

– General tube furnace with hinged door

– Double housing and low surface temperature (29~30℃ at 800℃)

– Recommended ideal running temperature is below 1000℃

– Great durability thanks to Kanthal heating element

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes and heating length. 50/80/100/120mm diameter and 300/600mm heating zone

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-80STG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Tube diameter | 80mm |

Controller | Programmable controller |

Sensor | K type |

Heater | 2.5kW |

Hot zone | 300mm |

Heating element | Kantal with ceramic molding |

Insulation | Ceramic |

External size | 500x370x540mm |

Weight | 32kg |

Power supply | 110V, 50/60Hz, 1p, 22A 220V, 50/60Hz, 1p, 11A |

SH-FU-50STG(300mm Length Hot Zone)

1200℃ tube furnace (50mm diameter tube and 300mm hot zone)

– General tube furnace with hinged door

– Double housing and low surface temperature (29~30℃ at 800℃)

– Recommended ideal running temperature is below 1000℃

– Great durability thanks to Kanthal heating element

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes and heating length. 50/80/100/120mm diameter and 300/600mm heating zone

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-50STG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Tube diameter | 50mm |

Controller | Programmable controller |

Sensor | K type |

Heater | 2kW |

Hot zone | 300mm |

Heating element | Kantal with ceramic molding |

Insulation | Ceramic |

External size | I500x360x520mm |

Weight | 27kg |

Power supply | 110V, 50/60Hz, 1p, 18A 220V, 50/60Hz, 1p, 9A |

SH-FU-6MSU 1800℃ high temp elevator furnace (6.2L)

1800℃ high temp elevator furnace (6.2L)

– General furnace with elevating mechanism

– General laboratory use with user safety

– Built in programmable controller

– Sintering

– Elevator furnaces are ideal for reduction, calcination, sintering, application of coatings, and other processes. SH Scientific system provides superior temperature uniformity, boasts energy efficient insulation, and delivers an ultra-pure atmosphere to process materials with minimal gas consumption.

Model | SH-FU-6MSU(18) |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Chamber volume | 6.2liters |

Controller | Programmable controller |

Sensor | B type |

Heater | 4.8kW |

Heating element | MoSi2 |

Insulation | Ceramic |

Power supply | 220V, 50/60Hz, 1p, 22A |

Net weight | 105kg |

Chamber size | 180x180x190mm |

External size | 510x580x1120mm |

SH-FU-1.5MGV

1200°C Muffle Furnace with Vacuum

– Recommended ideal running temperature is below 1000°C

– Complete atmospheric control for non-oxidation environment

– Creating multiple atmospheric enviroment (burning in air, purging air and pulling vacuum, flowing inert gas and sintering)

– No limitation on samples sizes due to squre inner chamber compared to the ones with tube furnace

– Supporting hardening, annealing, tempering, brazing and sintering with or without vacuum.

– Consist of individual 4 port for vacuum, vacuum release, gas in and gas out

– An optional MFC(Mass Flow Controller) for precise, responsive and stable gas management across 98 inert gas presets

– An Optional BPR(Back Pressure Regulator) to maintain positive pressure inside the chamber

– Offering full configration with vacuum pump, MFC, BPR, Digital vacuum meter as optional for perfect & precise experiment.

| Model | SH-FU-1.5MGV |

| Max Temp | 1200℃ (2192℉) |

| Temp Controller | Programmable Controller(SP590) |

Heater Capa | 1100 W |

| Capa | 1.5L |

| Dimension Internal (W×D×H) | 115x115x115mm 4.53×4.53×4.53” |

| Dimension External (W×D×H) | 740x610x590 mm 29.13×24.01×23.23” |

| Material External | Steel Plate with powder heating coated |

Heater Element | KANTHAL A-1 (Ceramic heating) |

Insulation | Ceramic Board & Wool (Ceramic fiber) |

| Electrical Requirements 120V, 50/60Hz, 1Φ | 9.2 A |

| Cat. No. | FU1.5MGV230 |

| Electrical Requirements 230V, 50/60Hz, 3Φ | N/A |

| Cat. No. | |

| Electrical Requirements 380V, 50/60Hz, 3Φ | N/A |

| Cat. No. |

Option

-Hybrid recorder

-MFC, BPR

SH-FU-31MGV

1200°C Muffle Furnace with Vacuum

– Recommended ideal running temperature is below 1000°C

– Complete atmospheric control for non-oxidation environment

– Creating multiple atmospheric enviroment (burning in air, purging air and pulling vacuum, flowing inert gas and sintering)

– No limitation on samples sizes due to squre inner chamber compared to the ones with tube furnace

– Supporting hardening, annealing, tempering, brazing and sintering with or without vacuum.

– Consist of individual 4 port for vacuum, vacuum release, gas in and gas out

– An optional MFC(Mass Flow Controller) for precise, responsive and stable gas management across 98 inert gas presets

– An Optional BPR(Back Pressure Regulator) to maintain positive pressure inside the chamber

– Offering full configration with vacuum pump, MFC, BPR, Digital vacuum meter as optional for perfect & precise experiment.

| Model | SH-FU-31MGV |

| Max Temp | 1200℃ (2192℉) |

| Temp Controller | Programmable Controller(SP590) |

Heater Capa | 6100 W |

| Capa | 31L |

| Dimension Internal (W×D×H) | 315x315x315mm 12.40×12.40×12.40” |

| Dimension External (W×D×H) | 940x710x820mm 37.01×27.95×32.28” |

| Material External | Steel Plate with powder heating coated |

Heater Element | KANTHAL A-1 (Ceramic heating) |

Insulation | Ceramic Board & Wool (Ceramic fiber) |

| Electrical Requirements 120V, 50/60Hz, 1Φ | N/A |

| Cat. No. | |

| Electrical Requirements 230V, 50/60Hz, 1Φ | 26.5 A |

| Cat. No. | FU31MGV230 |

| Electrical Requirements 230V, 50/60Hz, 3Φ | 15.1 A

|

| Cat. No. | FU31MGV230-3 |

| Electrical Requirements 380V, 50/60Hz, 3Φ | 9.1 A

|

| Cat. No. | FU31MGV380-3 |

SH-FU-10MGV

1200°C Muffle Furnace with Vacuum

– Recommended ideal running temperature is below 1000°C

– Complete atmospheric control for non-oxidation environment

– Creating multiple atmospheric enviroment (burning in air, purging air and pulling vacuum, flowing inert gas and sintering)

– No limitation on samples sizes due to squre inner chamber compared to the ones with tube furnace

– Supporting hardening, annealing, tempering, brazing and sintering with or without vacuum.

– Consist of individual 4 port for vacuum, vacuum release, gas in and gas out

– An optional MFC(Mass Flow Controller) for precise, responsive and stable gas management across 98 inert gas presets

– An Optional BPR(Back Pressure Regulator) to maintain positive pressure inside the chamber

– Offering full configration with vacuum pump, MFC, BPR, Digital vacuum meter as optional for perfect & precise experiment.

| Model | SH-FU-10MGV |

| Max Temp | 1200℃ (2192℉) |

| Temp Controller | Programmable Controller(SP590) |

Heater Capa | 3200 W |

| Capa | 10L |

| Dimension Internal (W×D×H) | 215x215x215mm 8.46×8.46×8.46” |

| Dimension External (W×D×H) | 840x610x700mm 33.07×24.01×27.56” |

| Material External | Steel Plate with powder heating coated |

Heater Element | KANTHAL A-1 (Ceramic heating) |

Insulation | Ceramic Board & Wool (Ceramic fiber) |

| Electrical Requirements 120V, 50/60Hz, 1Φ | N/A |

| Cat. No. | |

| Electrical Requirements 230V, 50/60Hz, 1Φ | 13.91A |

| Cat. No. | FU10MGV230 |

| Electrical Requirements 230V, 50/60Hz, 3Φ | N/A |

| Cat. No. | |

| Electrical Requirements 380V, 50/60Hz, 3Φ | N/A |

| Cat. No. |

SH-FU-31MGV 1200°C Muffle Furnace with Vacuum (31L)

1200°C Muffle Furnace with Vacuum

– Recommended ideal running temperature is below 1000°C

– Complete atmospheric control for non-oxidation environment

– Creating multiple atmospheric enviroment (burning in air, purging air and pulling vacuum, flowing inert gas and sintering)

– No limitation on samples sizes due to squre inner chamber compared to the ones with tube furnace

– Supporting hardening, annealing, tempering, brazing and sintering with or without vacuum.

– Consist of individual 4 port for vacuum, vacuum release, gas in and gas out

– An optional MFC(Mass Flow Controller) for precise, responsive and stable gas management across 98 inert gas presets

– An Optional BPR(Back Pressure Regulator) to maintain positive pressure inside the chamber

– Offering full configration with vacuum pump, MFC, BPR, Digital vacuum meter as optional for perfect & precise experiment.

SH-FU-4.5MHV 1500°C Muffle Furnace with Vacuum (4.5L)

1500°C Muffle Furnace with Vacuum

– Suitable for running atmosphere temperature below 1350℃

– Gas input after reaching vacuum condition in the rectangular inner chamber (Optimized for anoxic atmosphere)

– Consisted of individual 4 port for vacuum, vacuum release, gas in and gas out

– Mass gas Flow Controller (MFC) system installation (option)

– Back Pressure Regulator (BPR) system installation (option)

– Offering Full Package consist of Vacuum Pump, MFC, BPR, Digital Vacuummeter (option)

| Model | SH-FU-4.5MHV |

| Max Temp | 1500℃ (2732℉) |

| Temp Controller | Programmable Controller(SP590) |

| Sensor | R type |

Heater Capa | 3300 W |

| Capa | 4.5 L |

| Dimension Internal (W×D×H) | 150x200x150mm 5.91×7.87×5.91” |

| Dimension External (W×D×H) | 630x590x830mm 24.80×23.23×32.68” |

| Material External | Steel Plate with powder heating coated |

Heater Element | SIC |

Insulation | Ceramic Board & Wool (Ceramic fiber) |

| Electrical Requirements 230V ,50/60Hz, 1Φ | 14.4A

|

| Cat. No. | FU4.5MHV230 |

| Electrical Requirements 380V ,50/60Hz, 3Φ | N/A

|

| Cat. No. |

SH-FU-18.7MHV 1500°C Muffle Furnace with Vacuum (18.7L)

1500°C Muffle Furnace with Vacuum

– Suitable for running atmosphere temperature below 1350℃

– Gas input after reaching vacuum condition in the rectangular inner chamber (Optimized for anoxic atmosphere)

– Consisted of individual 4 port for vacuum, vacuum release, gas in and gas out

– Mass gas Flow Controller (MFC) system installation (option)

– Back Pressure Regulator (BPR) system installation (option)

– Offering Full Package consist of Vacuum Pump, MFC, BPR, Digital Vacuummeter (option)

| Model | SH-FU-18.7MHV |

| Max Temp | 1500℃ (2732℉) |

| Temp Controller | Programmable Controller(SP590) |

| Sensor | R type |

Heater Capa | 10000 W |

| Capa | 18.7 L |

| Dimension Internal (W×D×H) | 250x300x250mm 9.84×11.81×9.84” |

| Dimension External (W×D×H) | 1050X900X940mm 41.33×35.43×37.00” |

| Material External | Steel Plate with powder heating coated |

Heater Element | SIC |

Insulation | Ceramic Board & Wool (Ceramic fiber) |

| Electrical Requirements 230V ,50/60Hz, 1Φ | N/A

|

| Cat. No. | |

| Electrical Requirements 380V ,50/60Hz, 3Φ | 15.2A

|

| Cat. No. | FU18.7MHV380-3 |

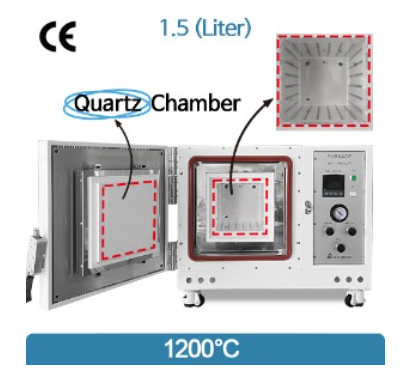

SH-FU-1.5MGVQ (1200°C Muffle Furnace with Quartz Chamber)

- Recommended ideal running temperature is below 1000°C

- Complete atmospheric control for non-oxidation environment

- Creating multiple atmospheric enviroment (burning in air, purging air and pulling vacuum, flowing inert gas and sintering)

- No limitation on samples sizes due to squre inner chamber compared to the ones with tube furnace

- Supporting hardening, annealing, tempering, brazing and sintering with or without vacuum.

- Ensuring non-contaminating clean room condition for delicate samples by the inner quartz chamber (including door back side)

- Maximize sample purity and heating element longevity by the inner quartz chamber

- Easy to clean the inner quartz chamber after experiment

- Consist of individual 4 port for vacuum, vacuum release, gas in and gas out covered with quartz

- An optional MFC(Mass Flow Controller) for precise, responsive and stable gas management across 98 inert gas presets

- An Optional BPR(Back Pressure Regulator) to maintain positive pressure inside the chamber

- Offering full configration with vacuum pump, MFC, BPR, Digital vacuummeter as optional for perfect & precise experiment.

| Model | SH-FU-1.5MGVQ |

|---|---|

| Max Temp | 1200℃ (2192℉) |

| Temp Controller | Programmable Controller(SP590) |

| Heater Capa | 1100 W |

| Capa | 1.5L |

| Dimension Internal (W×D×H) | (Quartz Chamber 3T) 109x109x109mm 4.29×4.29×4.29” |

| Dimension External (W×D×H) | 740x610x590 mm 29.13×24.01×23.23” |

| Material External | Steel Plate with powder heating coated |

| Heater Element | KANTHAL A-1 (Ceramic heating) |

| Insulation | Ceramic Board & Wool (Ceramic fiber) |

| Electrical Requirements 120V, 50/60Hz, 1Φ | 9.2 A |

| Cat. No. | FU1.5MGV120 |

| Electrical Requirements 230V, 50/60Hz, 1Φ | 4.8A |

| Cat. No. | FU1.5MGV230 |

| Electrical Requirements 230V, 50/60Hz, 3Φ | N/A |

| Cat. No. | |

| Electrical Requirements 380V, 50/60Hz, 3Φ | N/A |

| Cat. No. |

- • Option

- -Hybrid recorder

- -MFC, BPR

- • Safety Device

- -Automatic reset function incoming power cut

- -Buzzer on when set time arrived

- -Over temperature alarm

SH-FU-10MGVQ (1200°C Muffle Furnace with Quartz Chamber)

- Recommended ideal running temperature is below 1000°C

- Complete atmospheric control for non-oxidation environment

- Creating multiple atmospheric enviroment (burning in air, purging air and pulling vacuum, flowing inert gas and sintering)

- No limitation on samples sizes due to squre inner chamber compared to the ones with tube furnace

- Supporting hardening, annealing, tempering, brazing and sintering with or without vacuum.

- Ensuring non-contaminating clean room condition for delicate samples by the inner quartz chamber (including door back side)

- Maximize sample purity and heating element longevity by the inner quartz chamber

- Easy to clean the inner quartz chamber after experiment

- Consist of individual 4 port for vacuum, vacuum release, gas in and gas out covered with quartz

- An optional MFC(Mass Flow Controller) for precise, responsive and stable gas management across 98 inert gas presets

- An Optional BPR(Back Pressure Regulator) to maintain positive pressure inside the chamber

- Offering full configration with vacuum pump, MFC, BPR, Digital vacuummeter as optional for perfect & precise experiment.

| Model | SH-FU-10MGVQ |

|---|---|

| Max Temp | 1200℃ (2192℉) |

| Temp Controller | Programmable Controller(SP590) |

| Heater Capa | 3200 W |

| Capa | 10L |

| Dimension Internal (W×D×H) | (Quartz Chamber 5T) 205x205x205mm 8.07×8.07×8.07” |

| Dimension External (W×D×H) | 840x610x700mm 33.07×24.01×27.56” |

| Material External | Steel Plate with powder heating coated |

| Heater Element | KANTHAL A-1 (Ceramic heating) |

| Insulation | Ceramic Board & Wool (Ceramic fiber) |

| Electrical Requirements 120V, 50/60Hz, 1Φ | N/A |

| Cat. No. | |

| Electrical Requirements 230V, 50/60Hz, 1Φ | 13.91A |

| Cat. No. | FU10MGV230 |

| Electrical Requirements 230V, 50/60Hz, 3Φ | N/A |

| Cat. No. | |

| Electrical Requirements 380V, 50/60Hz, 3Φ | N/A |

| Cat. No. |

- • Option

- -Hybrid recorder

- -MFC, BPR

- • Safety Device

- -Automatic reset function incoming power cut

- -Buzzer on when set time arrived

- -Over temperature alarm

SH-FU-31MGVQ (1200°C Muffle Furnace with Quartz Chamber)

- Recommended ideal running temperature is below 1000°C

- Complete atmospheric control for non-oxidation environment

- Creating multiple atmospheric enviroment (burning in air, purging air and pulling vacuum, flowing inert gas and sintering)

- No limitation on samples sizes due to squre inner chamber compared to the ones with tube furnace

- Supporting hardening, annealing, tempering, brazing and sintering with or without vacuum.

- Ensuring non-contaminating clean room condition for delicate samples by the inner quartz chamber (including door back side)

- Maximize sample purity and heating element longevity by the inner quartz chamber

- Easy to clean the inner quartz chamber after experiment

- Consist of individual 4 port for vacuum, vacuum release, gas in and gas out covered with quartz

- An optional MFC(Mass Flow Controller) for precise, responsive and stable gas management across 98 inert gas presets

- An Optional BPR(Back Pressure Regulator) to maintain positive pressure inside the chamber

- Offering full configration with vacuum pump, MFC, BPR, Digital vacuummeter as optional for perfect & precise experiment.

| Model | SH-FU-31MGVQ |

|---|---|

| Max Temp | 1200℃ (2192℉) |

| Temp Controller | Programmable Controller(SP590) |

| Heater Capa | 6100 W |

| Capa | 31L |

| Dimension Internal (W×D×H) | (Quartz Chamber 5T) 305x305x305mm 12.00×12.00×12.00” |

| Dimension External (W×D×H) | 940x710x820mm 37.01×27.95×32.28” |

| Material External | Steel Plate with powder heating coated |

| Heater Element | KANTHAL A-1 (Ceramic heating) |

| Insulation | Ceramic Board & Wool (Ceramic fiber) |

| Electrical Requirements 120V, 50/60Hz, 1Φ | N/A |

| Cat. No. | |

| Electrical Requirements 230V, 50/60Hz, 1Φ | 26.5 A |

| Cat. No. | FU31MGV230 |

| Electrical Requirements 230V, 50/60Hz, 3Φ | 15.1 A |

| Cat. No. | FU31MGV230-3 |

| Electrical Requirements 380V, 50/60Hz, 3Φ | 9.1 A |

| Cat. No. | FU31MGV380-3 |

- • Option

- -Hybrid recorder

- -MFC, BPR

- • Safety Device

- -Automatic reset function incoming power cut

- -Buzzer on when set time arrived

- -Over temperature alarm

SH-FU-120LTG(600mm Length Hot Zone)

1200℃ tube furnace (120mm diameter tube and 600mm hot zone)

– General tube furnace with hinged door

– Double housing and low surface temperature (29~30℃ at 800℃)

– Recommended ideal running temperature is below 1000℃

– Great durability thanks to Kantal heating element

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SSR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes and heating length. 50/80/100/120mm diameter and 300/600mm heating zone

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-120LTG |

Max temperature | 1200℃ |

Continuous running temperature | 1000℃ |

Tube diameter | 120mm |

Controller | Programmable controller |

Sensor | K type |

Heater | 3.6kW |

Hot zone | 600mm |

Heating element | Kantal with ceramic molding |

Insulation | Ceramic |

External size | 810x460x630mm |

Weight | 105kg |

Power supply | 220V, 50/60Hz, 1p, 33A 220V, 50/60Hz, 3p, 18A 380V, 50/60Hz, 3p, 11A |

SH-FU-50TH (50mm diameter tube and 300mm hot zone)

1500℃ high temp tube furnace (50mm diameter tube and 300mm hot zone)

– High temp tube furnace with hinged door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1350℃

– Great durability thanks to SIC heating element and easy replacement

– R type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-50TH |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Tube diameter | 50mm |

Controller | Programmable controller |

Sensor | R type |

Heater | 5kW |

Hot zone | 300mm |

Heating element | SiC |

Insulation | Ceramic |

External size | 690x490x580mm |

Weight | 67kg |

Power supply | 220V, 50/60Hz, 1p, 23A |

SH-FU-80TH (80mm diameter tube and 300mm hot zone)

1500℃ high temp tube furnace (80mm diameter tube and 300mm hot zone)

– High temp tube furnace with hinged door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1350℃

– Great durability thanks to SIC heating element and easy replacement

– R type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-80TH |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Tube diameter | 80mm |

Controller | Programmable controller |

Sensor | R type |

Heater | 7kW |

Hot zone | 300mm |

Heating element | SiC |

Insulation | Ceramic |

External size | 690x520x610mm |

Weight | 72kg |

Power supply | 220V, 50/60Hz, 1p, 32A |

SH-FU-100TH (100mm diameter tube and 300mm hot zone)

1500℃ high temp tube furnace (100mm diameter tube and 300mm hot zone)

– High temp tube furnace with hinged door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1350℃

– Great durability thanks to SIC heating element and easy replacement

– R type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-100TH |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Tube diameter | 100mm |

Controller | Programmable controller |

Sensor | R type |

Heater | 13kW |

Hot zone | 300mm |

Heating element | SiC |

Insulation | Ceramic |

External size | 690x550x640mm |

Weight | 114kg |

Power supply | 220V, 50/60Hz, 1p, 60A |

SH-FU-120TH (120mm diameter tube and 300mm hot zone)

1500℃ high temp tube furnace (50mm diameter tube and 300mm hot zone)

– High temp tube furnace with hinged door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1350℃

– Great durability thanks to SIC heating element and easy replacement

– R type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Convenient design for sample loading

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-120TH |

Max temperature | 1500℃ |

Continuous running temperature | 1350℃ |

Tube diameter | 120mm |

Controller | Programmable controller |

Sensor | R type |

Heater | 9.6kW |

Hot zone | 300mm |

Heating element | SiC |

Insulation | Ceramic |

External size | 690x570x730mm |

Weight | 145kg |

Power supply | 220V, 50/60Hz, 1p, 44A |

SH-FU-50TS (50mm diameter tube and 300mm hot zone)

1700℃ high temp tube furnace (50mm diameter tube and 300mm hot zone)

– High temp tube furnace with solid door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1550℃

– Great durability thanks to SIC heating element and easy replacement of MoSi2

– R type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-50TS |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Tube diameter | 50mm |

Controller | Programmable controller |

Sensor | R type |

Heater | 4.1kW |

Hot zone | 300mm |

Heating element | SIC |

Insulation | MoSi2 |

External size | 690x550x980mm |

Weight | 67kg |

Power supply | 220V, 50/60Hz, 1p, 19A |

SH-FU-80TS (80mm diameter tube and 300mm hot zone)

1700℃ high temp tube furnace (80mm diameter tube and 300mm hot zone)

– High temp tube furnace with solid door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1550℃

– Great durability thanks to SIC heating element and easy replacement of MoSi2

– R type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-80TS |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Tube diameter | 80mm |

Controller | Programmable controller |

Sensor | R type |

Heater | 5.6kW |

Hot zone | 300mm |

Heating element | SIC |

Insulation | MoSi2 |

External size | 690x580x1010mm |

Weight | 72kg |

Power supply | 220V, 50/60Hz, 1p, 25A |

SH-FU-100TS (100mm diameter tube and 300mm hot zone)

1700℃ high temp tube furnace (50mm diameter tube and 300mm hot zone)

– High temp tube furnace with solid door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1550℃

– Great durability thanks to SIC heating element and easy replacement of MoSi2

– R type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-100TS |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Tube diameter | 100mm |

Controller | Programmable controller |

Sensor | R type |

Heater | 6.5kW |

Hot zone | 300mm |

Heating element | SIC |

Insulation | MoSi2 |

External size | 690x600x1030mm |

Weight | 114kg |

Power supply | 220V, 50/60Hz, 1p, 30A |

SH-FU-120TS (120mm diameter tube and 300mm hot zone)

1700℃ high temp tube furnace (120mm diameter tube and 300mm hot zone)

– High temp tube furnace with solid door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1550℃

– Great durability thanks to SIC heating element and easy replacement of MoSi2

– R type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-120TS |

Max temperature | 1700℃ |

Continuous running temperature | 1550℃ |

Tube diameter | 50mm |

Controller | Programmable controller |

Sensor | R type |

Heater | 8kW |

Hot zone | 300mm |

Heating element | SIC |

Insulation | MoSi2 |

External size | 690x640x1110mm |

Weight | 145kg |

Power supply | 220V, 50/60Hz, 1p, 36A |

SH-FU-50TS (50mm diameter tube and 300mm hot zone)

1800℃ high temp tube furnace (50mm diameter tube and 300mm hot zone)

– High temp tube furnace with solid door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1650℃

– Great durability thanks to SIC heating element and easy replacement of MoSi2

– B type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-50TS |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Tube diameter | 50mm |

Controller | Programmable controller |

Sensor | B type |

Heater | 3.1kW |

Hot zone | 300mm |

Heating element | SIC |

Insulation | MoSi2 |

External size | 690x550x980mm |

Weight | 67kg |

Power supply | 220V, 50/60Hz, 1p, 14A |

SH-FU-80TS (80mm diameter tube and 300mm hot zone)

1800℃ high temp tube furnace (80mm diameter tube and 300mm hot zone)

– High temp tube furnace with solid door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1650℃

– Great durability thanks to SIC heating element and easy replacement of MoSi2

– B type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-80TS |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Tube diameter | 80mm |

Controller | Programmable controller |

Sensor | B type |

Heater | 4.2kW |

Hot zone | 300mm |

Heating element | SIC |

Insulation | MoSi2 |

External size | 690x580x1010mm |

Weight | 72kg |

Power supply | 220V, 50/60Hz, 1p, 19A |

SH-FU-100TS (100mm diameter tube and 300mm hot zone)

1800℃ high temp tube furnace (100mm diameter tube and 300mm hot zone)

– High temp tube furnace with solid door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1650℃

– Great durability thanks to SIC heating element and easy replacement of MoSi2

– B type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-100TS |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Tube diameter | 100mm |

Controller | Programmable controller |

Sensor | B type |

Heater | 4.9kW |

Hot zone | 300mm |

Heating element | SIC |

Insulation | MoSi2 |

External size | 690x600x1030mm |

Weight | 114kg |

Power supply | 220V, 50/60Hz, 1p, 22A |

SH-FU-120TS (120mm diameter tube and 300mm hot zone)

1800℃ high temp tube furnace (120mm diameter tube and 300mm hot zone)

– High temp tube furnace with solid door

– Double housing and low surface temperature

– Recommended ideal running temperature is below 1650℃

– Great durability thanks to SIC heating element and easy replacement of MoSi2

– B type thermocouple

– Suitable for gas exchange experiment

– Light weight and prompt heat up thanks to ceramic insulation

– Built in programmable controller. 5 patterns and 9 segment/pattern. Total 45 segments

– Built in over temp protector

– SCR operation and built in programmable controller provides low noise operation and precise temp control (+/-1℃)

– Wide choice of applicable tube sizes. 50/80/100/120mm diameter.

– Wide choice of tube materials. Quartz, ceramic, alumina and alloy

Model | SH-FU-120TS |

Max temperature | 1800℃ |

Continuous running temperature | 1650℃ |

Tube diameter | 120mm |

Controller | Programmable controller |

Sensor | B type |

Heater | 6kW |

Hot zone | 300mm |

Heating element | SIC |

Insulation | MoSi2 |

External size | 690x640x1110mm |

Weight | 145kg |

Power supply | 220V, 50/60Hz, 1p, 27A |

1200℃ Tube Furnace Package(300mm/600mm)

Here is the proud supply reference of SH Scientific Muffle Furnace, Tube Furnace and Vacuum Furnace from customers and industries in US and Canada.

- Destructive testing laboratories who carry heat treatment of ceramic, alloy, titanium and etc for aerospace and metallic production industries.

●Building companies who transforms metallic power such as nickel alloy into sintered materials by sintering.

● Material technology providers who develop polymer composites and graphene materials.