Blender Bags with Filters

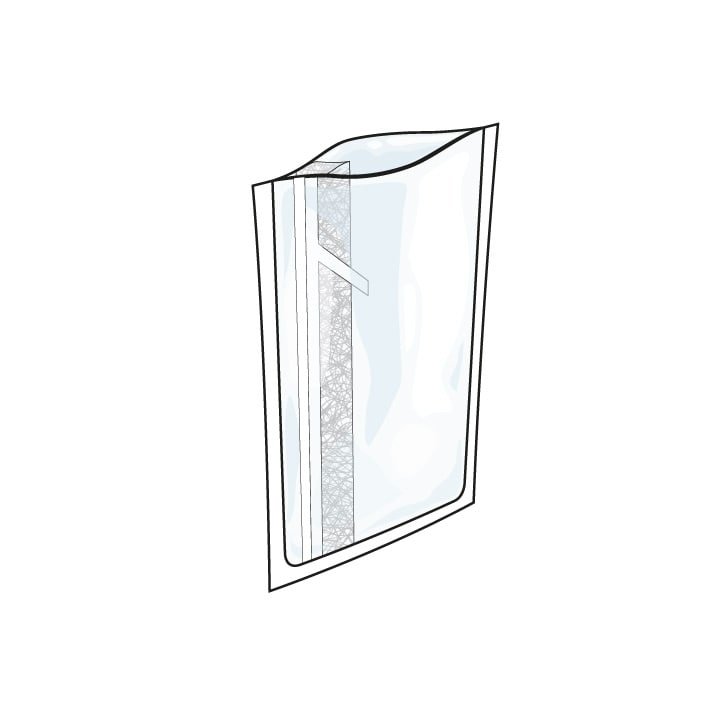

BagFilter Roll

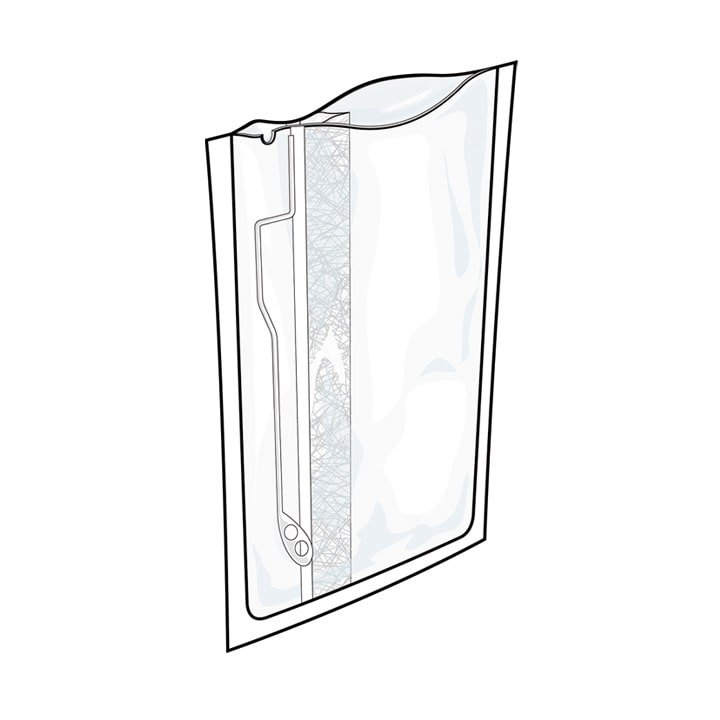

BagFilter Pipet

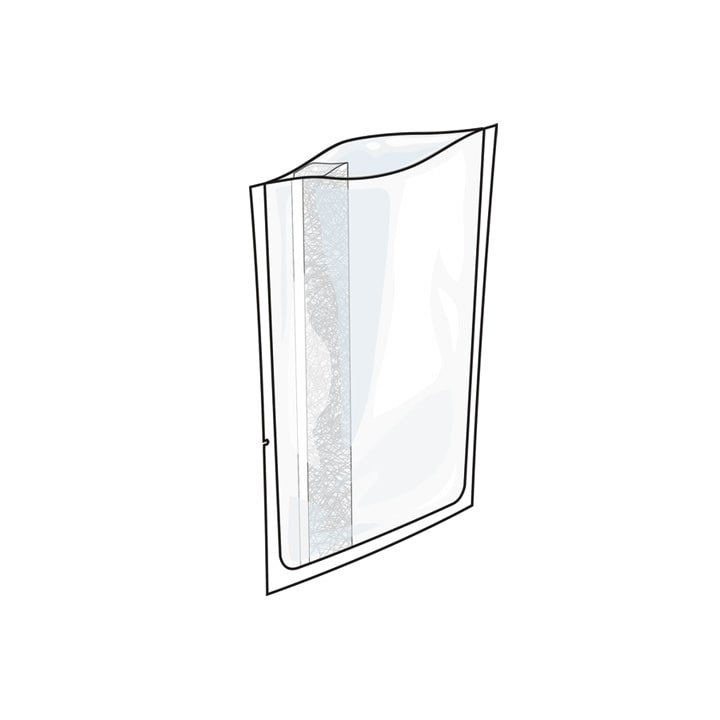

BagFilter Pipet & Roll

BagFilter P

BagFilter S

BagFilter Pull-Up

BagFilter XF

BagPage +

BagPage F

BagPage R

BagPage XR

BagFilter Roll

BagFilter Roll

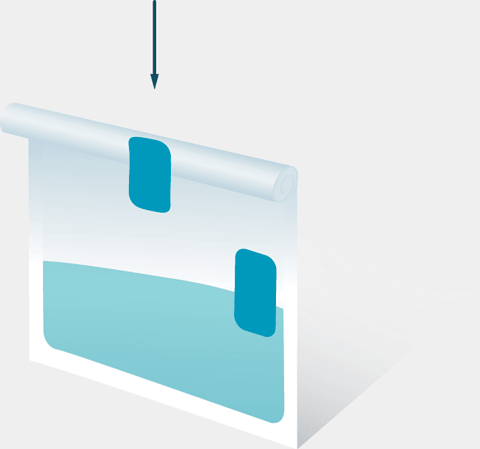

Lateral filter bag with built-in closure

Ref 111 700 (400 mL)

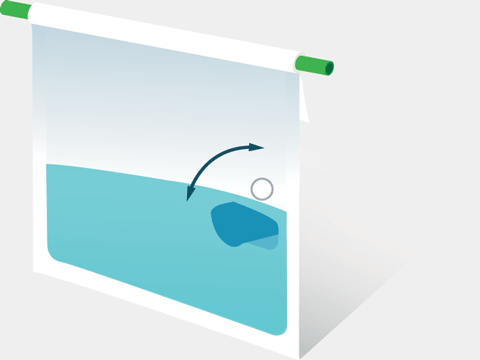

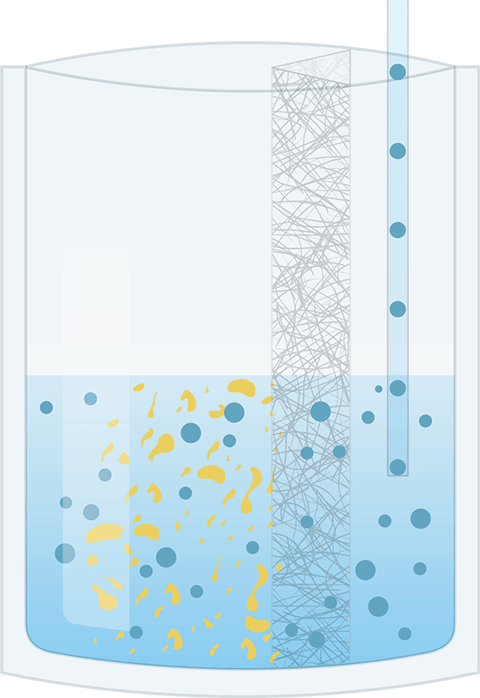

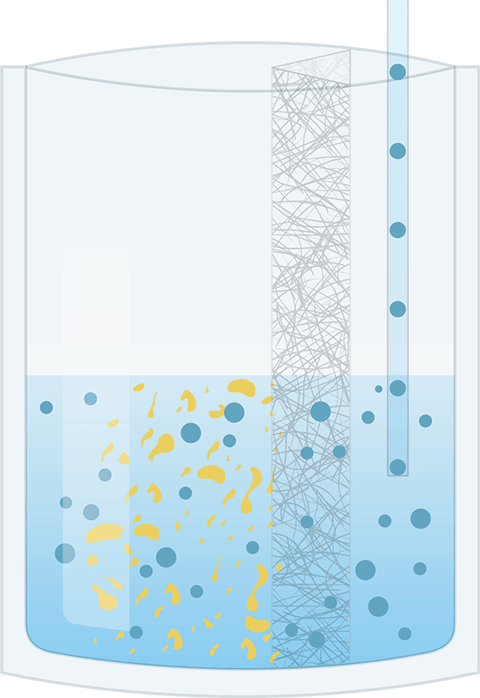

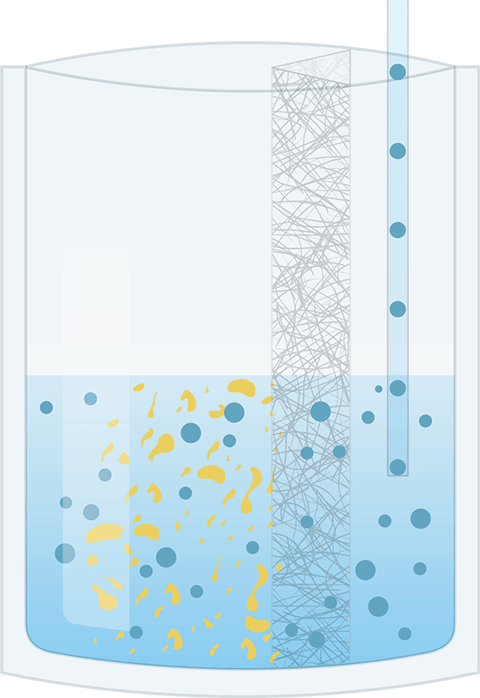

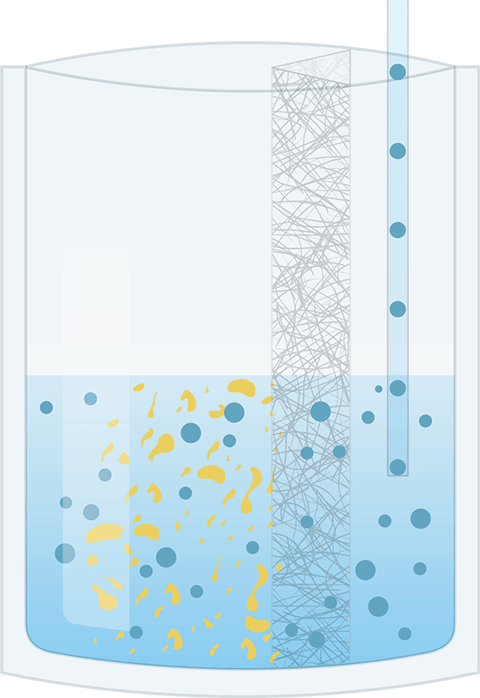

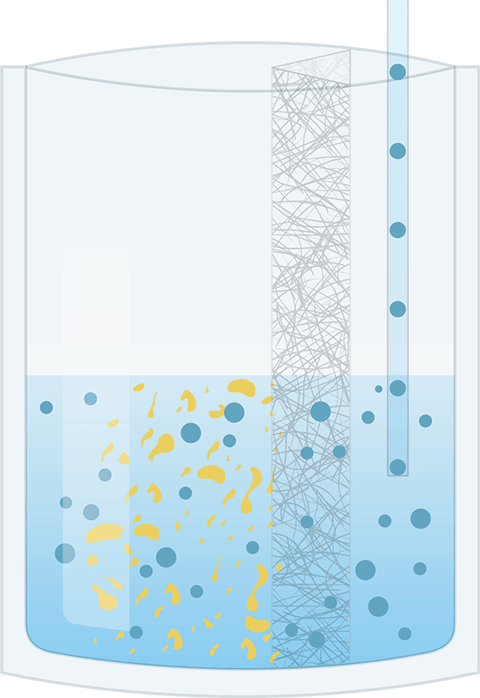

BagFilter Roll is a blender bag with a lateral non-woven filter for all microbiological analyses. The reclosable sticker allows a water-tight closure of the bag.

- Built-in closure sticker

- Optimal blending volume: 50 – 300 mL

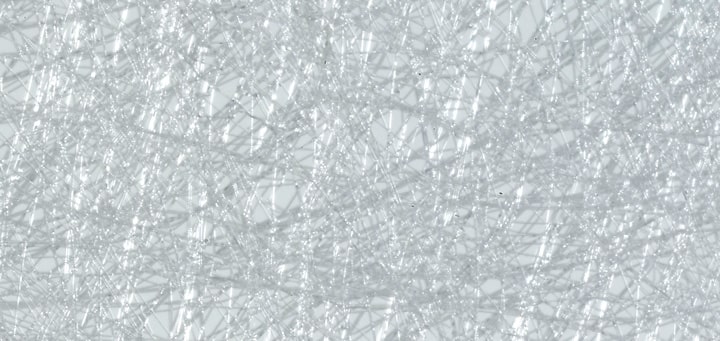

- Porosity of the non-woven filter: < 250 micrometers

SPECIFICATIONS

| BagFilter Roll | |

| Reference | 111 700 |

| Ideal | For homogenizing fibrous samples |

| Built-in sticker for bag closure | ✔ |

| Precut for pipetting | ✔ |

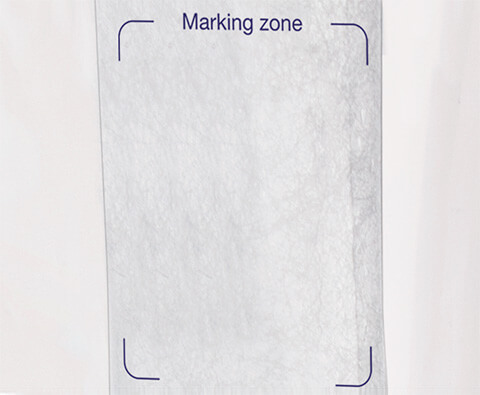

| Marking zone | ✔ |

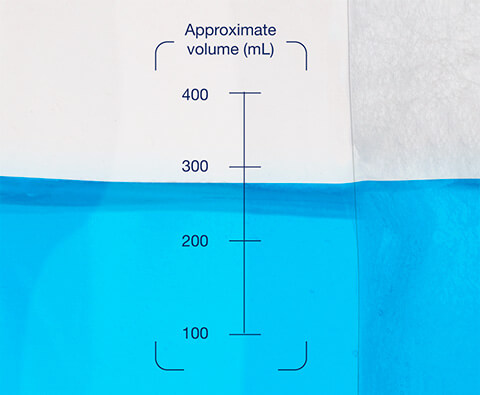

| Volume index | ✔ |

| Max blending volume | 400 mL |

| Optimal blending volume | 50-300 mL |

| Optimal volume for pipetting | 250 mL |

| Type of bag | Bag with lateral filter |

| Bag composition | Multilayer : reinforced multicoated complex |

| Type of filter | Lateral non-woven filter |

| Filter porosity | < 250 micrometers |

| Bag dimensions | 190 x 300 mm |

| Gamma ray treated | 5 to 12 KGy |

| Average shelf-life | 5 years |

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) |

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) |

| Approved for food contact | Regulation (EC) N° 1935/2004 |

| Box (w x d x h) | 35 x 22 x 15 cm |

| Gross weight | 5.3 kg |

| Pack of | 25 |

| Box of | 500 |

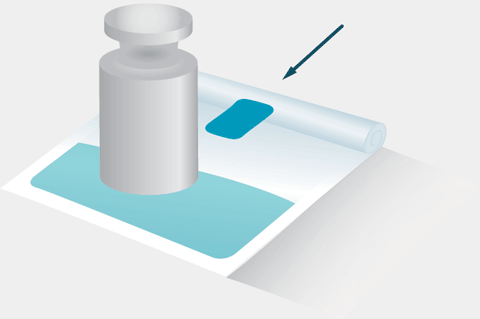

Quick sticker closure

Without any extra tools, simply close with the built-in closure sticker.

BagFilter Roll

With other products

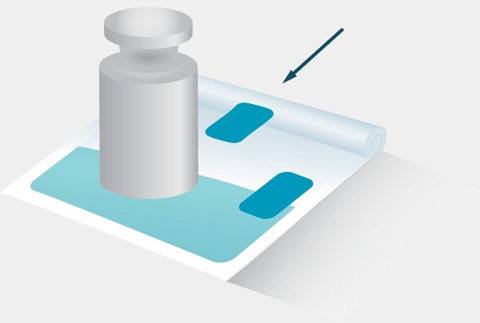

Extra resistant closure

Get an extra-resistant closure within seconds. Waterproof and resistant up to 5 kg pressure.

BagFilter Roll

With other

products

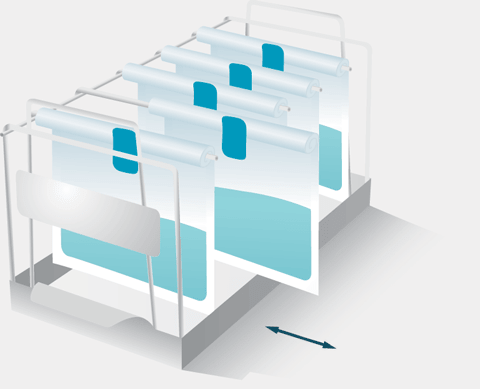

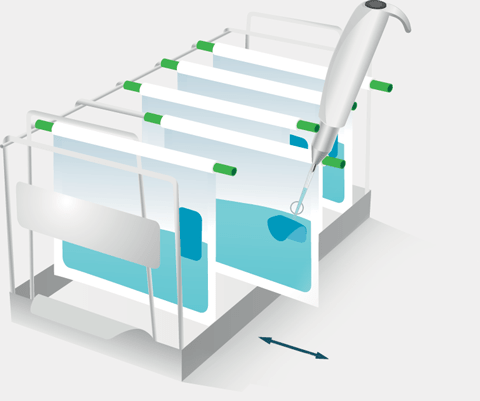

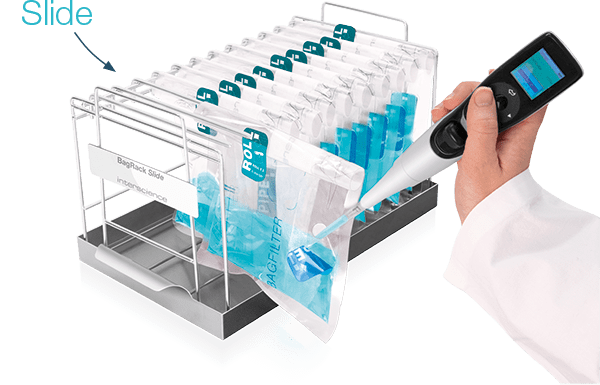

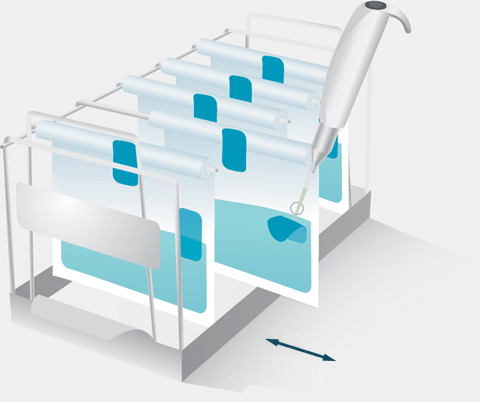

Ideal with BagRack Slide

Slide your bag by the side in a BagRack Slide.

Benefit from a great ergonomics of work of the preparation until the plating of the sample.

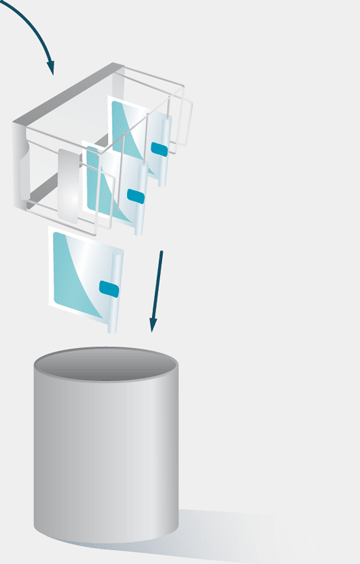

Rapid & hygienic disposal

After work, waste disposal is much quicker and without any sample dripping.

Quick

Clean

Applications

BagFilter Roll is used for analysis in the food industries, environmental and public research institutes.

The integrated closure is suitable for all steps of the sample preparation, from sample collection to analysis.

BagFilter Pipet & Roll – Lateral filter blender bags with built-in closure : Overview of the range

BagFilter Pipet

BagFilter Pipet

Lateral filter bag with easy pipet access

Ref 111 710 (400 mL)

BagFilter Pipet is a bag with a non-woven side filter. Coupled with the bag rack BagRack Slide, it offers perfect ergonomics. The repositionable sticker allows successive pipetting. BagFilter Pipet is ideal for Pathogens researches, avoiding cross-contaminations..

- Easy pipetting access

- Optimal volume for blending: 50 – 300 mL

- Porosity of the non-woven filter: < 250 micrometers

SPECIFICATIONS

| BagFilter Pipet | |

| Reference | 111 710 |

| Ideal | For homogenizing fibrous samples |

| Reclosable sticker for easy pipetting with a micropipette cone | ✔ |

| Marking zone | ✔ |

| Volume index | ✔ |

| Max blending volume | 400 mL |

| Optimal blending volume | 50-300 mL |

| Optimal volume for pipetting | 250 mL |

| Type of bag | Bag with lateral filter |

| Bag composition | Multilayer : reinforced multicoated complex |

| Type of filter | Lateral non-woven filter |

| Filter porosity | < 250 micrometers |

| Bag dimensions | 190 x 300 mm |

| Gamma ray treated | 5 to 12 KGy |

| Average shelf-life | 5 years |

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) |

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) |

| Approved for food contact | Regulation (EC) N° 1935/2004 |

| Box (w x d x h) | 35 x 22 x 15 cm |

| Gross weight | 5.4 kg |

| Pack of | 25 |

| Box of | 500 |

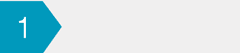

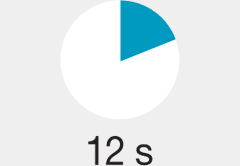

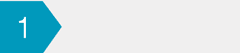

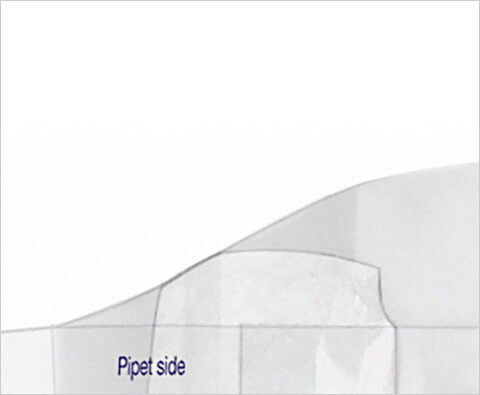

Easy pipetting access

During multiple pipettings for pathogens research, open and close the pipet access easily without opening the bag from the top.

BagFilter Pipet is compatible with any type of pipet.

Number of manipulations

BagFilter Pipet

With other products

Pathogens research

The low pipetting height is great for work under biosafety cabinets and ideal with pipet cones for pathogens research.

BagFilter Pipet

With other

products

Great ergonomics

BagFilter Pipet associated with BagRack Slide improves your workstation. Timed pipetting is optimized without the risks of R.S.I..

BagFilter Pipet

With other

products

Applications

BagFilter Pipet is used for analyses in the food industries, environmental and public institutes.

It provides great ergonomics in solid sample preparation and provides security when pipetting for pathogen research.

BagFilter Pipet optimizes the organization during multiple pipettings.

BagFilter Pipet & Roll – Lateral filter blender bags with built-in closure : Overview of the range

BagFilter Pipet & Roll

BagFilter Pipet & Roll

Lateral filter bag with pipet access and built-in closure

Ref 111 720 (400 mL)

BagFilter Pipet & Roll is a bag with a non-woven side filter. The Pipet sticker allows successive pipetting. The sticker Roll ensures a tight closure of the bag. It is ideal for pre-enrichment of pathogens.

- Easy pipetting access sticker

- Built-in closure sticker

- Optimal volume for blending: 50 – 300 mL

- Porosity of the non-woven filter: < 250 micrometers

SPECIFICATIONS

| BagFilter Pipet & Roll | |

| Reference | 111 720 |

| Ideal | For homogenizing fibrous samples |

| Built-in sticker for bag closure | ✔ |

| Reclosable sticker for easy pipetting with a micropipette cone | ✔ |

| Marking zone | ✔ |

| Volume index | ✔ |

| Max blending volume | 400 mL |

| Optimal blending volume | 50-300 mL |

| Optimal volume for pipetting | 250 mL |

| Type of bag | Bag with lateral filter |

| Bag composition | Multilayer : reinforced multicoated complex |

| Type of filter | Lateral non-woven filter |

| Filter porosity | < 250 micrometers |

| Bag dimensions | 190 x 300 mm |

| Gamma ray treated | 5 to 12 KGy |

| Average shelf-life | 5 years |

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) |

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) |

| Approved for food contact | Regulation (EC) N° 1935/2004 |

| Box (w x d x h) | 35 x 22 x 15 cm |

| Gross weight | 5,4 kg |

| Pack of | 25 |

| Box of | 500 |

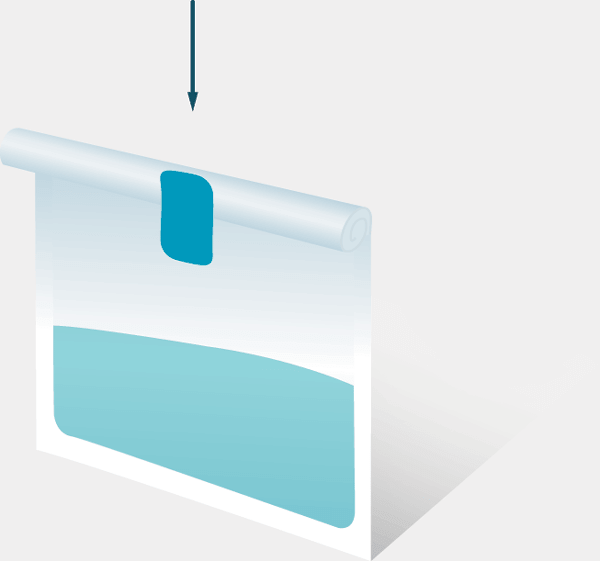

How does it work?

- Roll

Roll

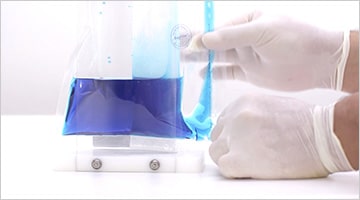

Simply roll your bag 3 times and close it with the pre-cut sticker. The closure is waterproof..

- Slide

Slide

Slide your bag to the side in a BagRack Slide. Great ergonomics from sample preparation to sample plating.

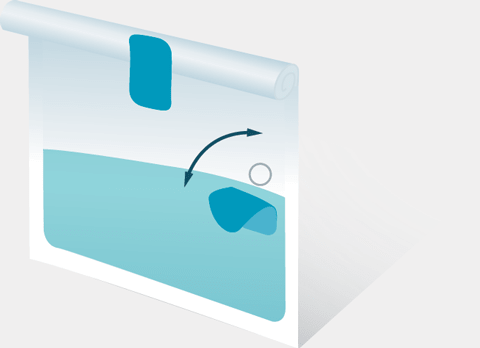

- Pipet

Pipet

Open/close the pipet access easily with the sticker closure. The pipetting zone, in the lower part of the bag, enables easy pipetting access of the filtrate. BagFilter Pipet & Roll is compatible with any pipet. It prevents musculoskeletal disorders and cross-contaminations.

Quick sticker closure closure

Without any extra tools, simply close with the built-in closure sticker.

BagFilter Pipet & Roll

With other products

Extra resistant closure

Get an extra-resistant closure within seconds. Waterproof and resistant up to 5 kg pressure.

BagFilter

Pipet & Roll

With other

products

Easy pipetting access

During multiple pipettings for pathogens research, open and close the pipet access easily without opening the bag from the top.

Number of manipulations

BagFilter Pipet & Roll

With other products

Pathogens research

The low pipetting height is great for work under laminar flow cabinets and ideal with pipet tips for Pathogens research.

BagFilter

Pipet & Roll

With other

products

Slide your bag

Use the BagRack Slide as a stand for your multiple pipetting and sample storage, for great ergonomic work. Prevents R.S.I. (repetitive strain injury).

BagFilter

Pipet & Roll

With other

products

Rapid & hygienic disposal

After work, waste disposal is much quicker and without any sample dripping.

Quick

Clean

Applications

BagFilter Pipet & Roll is used for analyses in the food industries, environmental and public research institutes.

It provides ergonomics in solid sample preparation and ensures security when pipetting for pathogen research.

BagFilter Pipet & Roll optimizes the organization of timed pipetting.

BagFilter Pipet & Roll – Lateral filter blender bags with built-in closure : Overview of the range

BagFilter P

BagFilter P

Lateral filter bag

Ref 111 425 (400 mL)

Ref 111 200 (2000 mL)

Ref 113 510 (3500 mL)

BagFilter P is a bag with a non-woven side filter. Filtration is instantaneous without the risk of cross-contamination. It is ideal for pipetting.

- Porosity of the filter: < 250 micrometers

- Compatible with any laboratory blender

- Multilayer: reinforced multicoated complex

- Rigid and transparent

SPECIFICATIONS

| BagFilter P 400 | BagFilter P 2000 | BagFilter P 3500 | |

| Reference | 111 425 | 111 200 | 113 510 |

| Ideal | For pipetting homogenizing fibrous samples | ||

| Precut for pipetting | ✔ | ||

| Marking zone | ✔ | ||

| Volume index | ✔ | ||

| Closing zone (patent pending) | ✔ | ||

| Max blending volume | 400 mL | 2000 mL | 3750 mL |

| Optimal blending volume | 50-300 mL | 400-1500 mL | 400-3750 mL |

| Type of bag | Bag with lateral filter | ||

| Bag composition | Multilayer: reinforced multicoated complex | ||

| Type of filter | Lateral non-woven filter | ||

| Filter porosity | < 250 microns | ||

| Bag dimensions | 190 x 300 mm | 250 x 380 mm | 380 x 600 mm |

| Gamma ray treated | 5 to 12 KGy | ||

| Average shelf-life | 15 years | ||

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) | ||

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) | ||

| Approved for food contact | Regulation (EC) N° 1935/2004 | ||

| Storage conditions | In a temperate and dry place, away from humidity and light | ||

| Box (w x d x h) | 35 x 22 x 15 cm | 47.5 x 28.5 x 13.5 cm | 41 x 33.5 x 11 cm |

| Gross weight | 5 kg | 6.7 kg | 4.2 kg |

| Pack of | 25 | 25 | 10 |

| Box of | 500 | 400 | 100 |

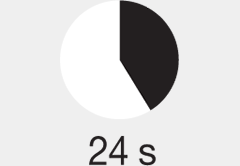

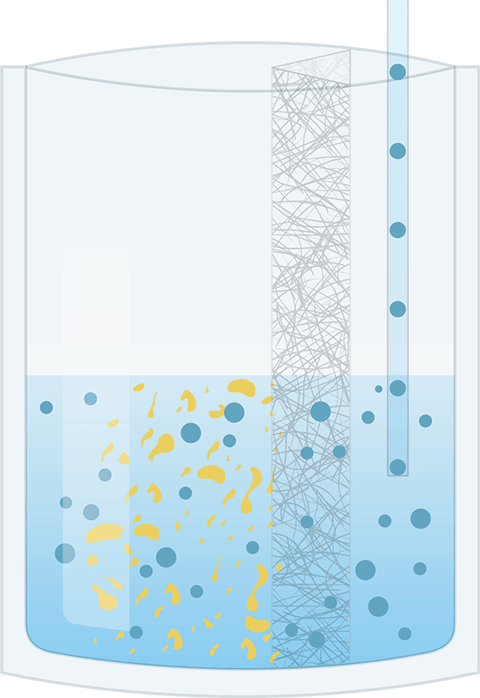

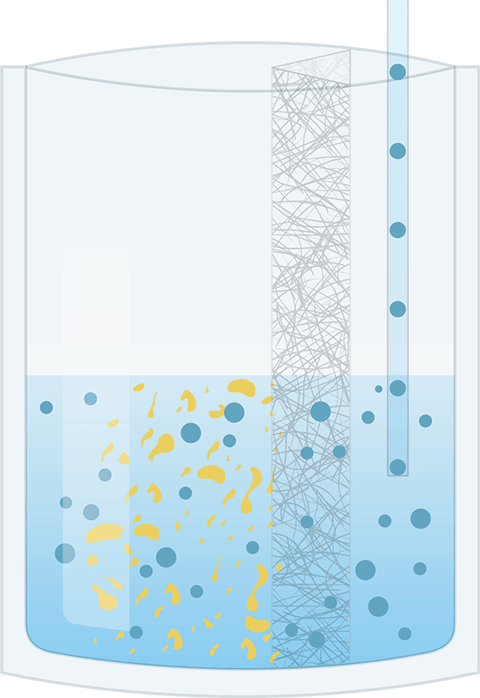

One bag for the full analysis

With BagFilter, use the same bag to sample, blend, filter and pipet. This will prevent cross-contamination and save time.

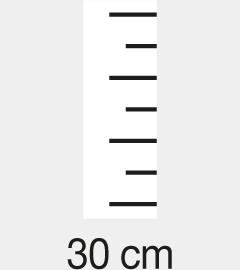

1. Place the sample

2. Dilute the sample

3. Blend the sample

4. Pipet the filtrate

Easy pipetting

BagFilter P is a filter bag that simplifies the pipetting of the filtrate. Pipetting is debris-free thanks to the integrated filter.

A pre-cut at the bottom of the bag facilitates the use of micro-pipettes and prevents cross-contamination.

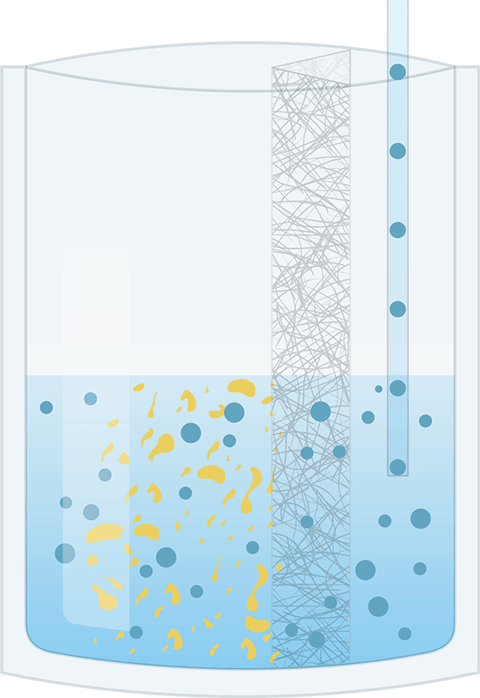

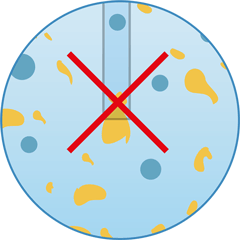

Instant filtration

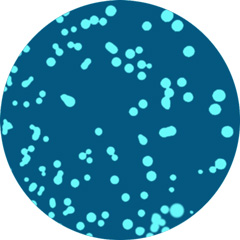

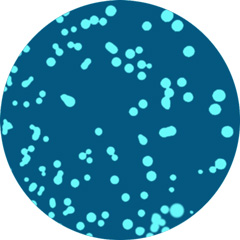

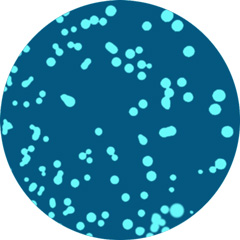

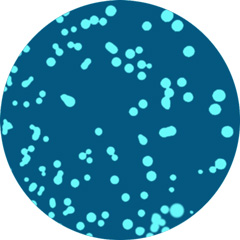

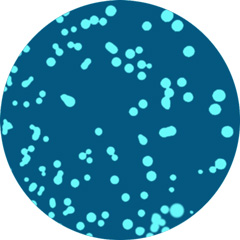

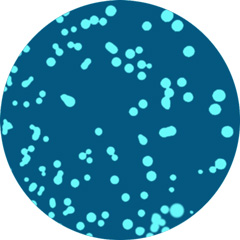

Filtration is done during blending. There is no need to wait for sedimentation of the debris to pipet.

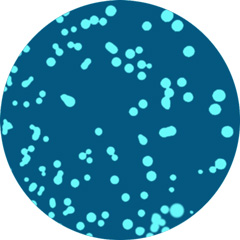

The filtrate is particle-free, so there is no debris on the Petri dish. Reading is thus facilitated and the results more precise.

No blocked pipet from particles

Debris free

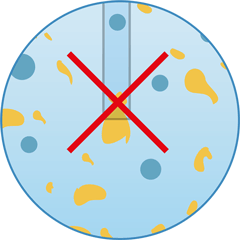

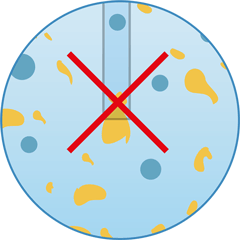

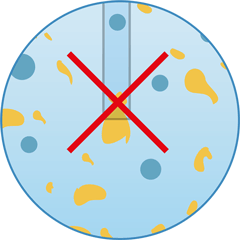

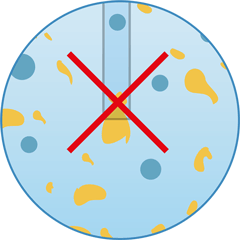

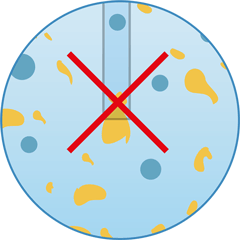

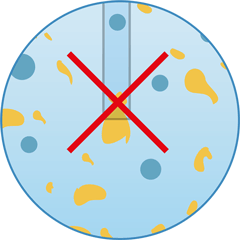

No cross-contaminations

There is no contact between the sample and the mixer during homogenization. This avoids cross-contamination.

The bag can be closed with a BagClip or welded. It is processed by gamma ray.

Before

After

Marking zone

Easily identify

the samples.

Volume indication

To quickly visualize the amount

of diluent in the bag.

Enlarged opening

Facilitates the insertion of the solid

sample and the pipettes’ tips.

“Closing Zone” Marking

Allows intuitive placement of the closing clip for leak-free closure. This ensures cleanliness of the incubators and saves time in handling.

Applications

BagFilter adapts itself to every stage of sample preparation. Depending on the protocols, it is used in the food, pharmaceutical, cosmetic, environmental, animal health and public institutes:

- BagFilter 400 mL is suitable for samples of 25 g in the food industry.

- BagFilter 2000 mL is ideal for the search for Salmonella via the PCR method for example. It is also used for sample preparation up to 1500 mL with a test portion of 100 / 150g.

- BagFilter 3500 mL is particularly used in the food industry for sample pooling with a sample size up to 375 g.

BagFilter P 400 – Lateral filter blender bags: “Closing Zone” marking

BagFilter S

BagFilter S

Lateral filter bag

Ref 112 425 (400 mL)

BagFilter S is a bag with a non-woven side filter. Through an intermediate weld, pour the filtrate without residues or particles.

- Porosity of the filter: < 250 micrometers

- Compatible with any laboratory blender

- Multilayer: reinforced multicoated complex

- Rigid and transparent

SPECIFICATIONS

| BagFilter S 400 | |

| Reference | 112 425 |

| Ideal | For pouring: with a weld to retain particles |

| Max blending volume | 400 mL |

| Optimal blending volume | 50-300 mL |

| Type of bag | Bag with lateral filter |

| Bag composition | Multilayer : reinforced multicoated complex |

| Type of filter | Lateral non-woven filter |

| Filter porosity | < 250 micrometers |

| Bag dimensions | 190 x 300 mm |

| Gamma ray treated | 5 to 12 KGy |

| Average shelf-life | 15 years |

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) |

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) |

| Approved for food contact | Regulation (EC) N° 1935/2004 |

| Storage conditions | In a temperate and dry place, away from humidity and light |

| Box (w x d x h) | 35 x 22 x 15 cm |

| Gross weight | 5 kg |

| Pack of | 25 |

| Box of | 500 |

One bag for the full analysis

With BagFilter, use the same bag to sample, blend, filter and pipet. This will prevent cross-contamination and save time.

1. Place the sample

2. Dilute the sample

3. Blend the sample

4. Pipet the filtrate

For pouring

BagFilter S is a filter bag that allows easy pouring of the filtrate thanks to a weld integrated in the filter.

Instant filtration

Filtration is done during blending. There is no need to wait for sedimentation of the debris to pipet.

The filtrate is particle-free, so there is no debris on the Petri dish. Reading is thus facilitated and the results more precise.

No blocked pipet from particles

Debris free

No cross-contaminations

There is no contact between the sample and the mixer during homogenization. This avoids cross-contamination.

The bag can be closed with a BagClip or welded. It is processed by gamma ray.

Before

After

Applications

BagFilter is used according to protocols in the food, pharmaceutical, cosmetic, environmental and public research institutes.

It adapts itself to every step of the sample preparation.

BagFilter – Lateral filter blender bags: Overview of the range

BagFilter Pull-Up

BagFilter Pull-Up

Lateral filter bag

Ref 111 625 (400 mL)

BagFilter Pull-Up is a bag with a non-woven side filter. It has been specially designed to make pipetting easy with any type of pipette and short tips (Patented).

- For PCR and small volumes: < 1000 µL

- Filter porosity < 50 micrometers

- Compatible with any laboratory blender

- Multilayer: reinforced multicoated complex

SPECIFICATIONS

| BagFilter Pull-Up 400 | |

| Reference | 111 625 |

| Ideal | For PCR and small volumes (≤1000 µL) |

| Max blending volume | 400 mL |

| Optimal blending volume | 50-300 mL |

| Type of bag | Bag with lateral filter |

| Bag composition | Multilayer: reinforced multicoated complex |

| Type of filter | Lateral non-woven filter |

| Filter porosity | < 50 micrometers |

| Bag dimensions | 190 x 300 mm |

| Gamma ray treated | 5 to 12 KGy |

| Average shelf-life | 15 years |

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) |

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) |

| Approved for food contact | Regulation (EC) N° 1935/2004 |

| Storage conditions | In a temperate and dry place, away from humidity and light |

| Box (w x d x h) | 34 x 22 x 26 cm |

| Gross weight | 5.6 kg |

| Pack of | 25 |

| Box of | 500 |

One bag for the full analysis

With BagFilter, use the same bag to sample, blend, filter and pipet. This will prevent cross-contamination and save time.

1. Place the sample

2. Dilute the sample

3. Blend the sample

4. Pipet the filtrate

Pull-Up system: easy pipetting for short tips

With a unique filter design, the Pull-Up system is ideal for PCR analysis and small volumes (<1000 µL).

It facilitates pipetting with pipettes / short tips (≥ 4 cm) and avoids cross-contamination. PATENTED

Instant filtration

Filtration is done during blending. There is no need to wait for sedimentation of the debris to pipet.

The filtrate is particle-free, so there is no debris on the Petri dish. Reading is thus facilitated and the results more precise.

No blocked pipet from particles

Debris free

No cross-contaminations

There is no contact between the sample and the mixer during homogenization. This avoids cross-contamination.

The bag can be closed with a BagClip or welded. It is processed by gamma ray.

Before

After

Applications

BagFilter Pull-Up is used according to the protocols in food, pharmaceutical, cosmetic, environmental and public research institutes. It is adapted to all the steps of sample preparation. BagFilter Pull-Up is suitable for capillary techniques such as flow cytometry and PCR.

BagFilter – Lateral filter blender bags: Overview of the range

BagFilter XF

BagFilter XF

Lateral filter bag

Ref 111 325 (400 mL)

BagFilter XF is a blender bag with a non-woven side filter. It is particularly suitable for samples containing fine particles. BagFilter XF is ideal for optimal use of capillary analysis systems (flow cytometry, PCR, qPCR, Spiral …)

- Filter porosity: < 20 micrometers

- Compatible with any laboratory blender

- Multilayer: reinforced multicoated complex

- Rigid and transparent

SPECIFICATIONS

| BagFilter XF 400 | |

| Reference | 111 325 |

| Ideal | For the use of PCR methods and samples with small particles (powders, cosmetics) |

| Max blending volume | 400 mL |

| Optimal blending volume | 50-300 mL |

| Type of bag | Bag with lateral filter |

| Bag composition | Multilayer : reinforced multicoated complex |

| Type of filter | Lateral non-woven filter |

| Filter porosity | < 20 micrometers |

| Bag dimensions | 190 x 300 mm |

| Gamma ray treated | 5 to 12 KGy |

| Average shelf-life | 15 years |

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) |

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) |

| Approved for food contact | Regulation (EC) N° 1935/2004 |

| Storage conditions | In a temperate and dry place, away from humidity and light |

| Box (w x d x h) | 35 x 22 x 15 cm |

| Gross weight | 6 kg |

| Pack of | 25 |

| Box of | 500 |

One bag for the full analysis

With BagFilter, use the same bag to sample, blend, filter and pipet. This will prevent cross-contamination and save time.

1. Place the sample

2. Dilute the sample

3. Blend the sample

4. Pipet the filtrate

Extra-low porosity filter

BagFilter XF is a bag with an extra-low porosity side filter: <20 microns. It is ideal for samples containing fine particles (powders, dusts, spices…) and organic elements. BagFilter XF is used for capillary analysis systems (PCR, flow cytometry…).

Extra-low porosity filter < 20 µm

Instant filtration

Filtration is done during blending. There is no need to wait for sedimentation of the debris to pipet.

The filtrate is particle-free, so there is no debris on the Petri dish. Reading is thus facilitated and the results more precise.

No blocked pipet from particles

Debris free

No cross-contaminations

There is no contact between the sample and the mixer during homogenization. This avoids cross-contamination.

The bag can be closed with a BagClip or welded. It is processed by gamma ray.

Before

After

Applications

BagFilter XF is used according to the protocols in food, pharmaceutical, cosmetic, environmental and public research institutes. BagFilter XF is suited for capillary analysis systems such as flow cytometry and PCR. BagFilter XF is ideal for samples with fine particles (spices, powders, dust…). It is also designed to separate the organic elements of the filtrate (fat, sugar, food gum, excipients…)

BagFilter – Lateral filter blender bags: Overview of the range

BagPage +

BagPage +

Full-page filter bag

Ref 121 025 (100 mL)

Ref 122 025 (400 mL)

Ref 122 200 (2000 mL)

Ref 123 010 (3500 mL)

BagPage + is a blender bag with a full-screen microperforated filter. Filtration is instantaneous without risks of cross contaminations. A unique welding system on the bag allows pipetting without error.

- Filter porosity: 280 micrometers

- Compatible with any laboratory blender

- Multilayer: reinforced multicoated complex

- Rigid and transparent

SPECIFICATIONS

| BagPage 100 | BagPage + 400 | BagPage + 2000 | BagPage + 3500 | |

| Reference | 121 025 | 122 025 | 122 200 | 123 010 |

| Ideal | For homogenizing pasty samples | |||

| Max blending volume | 100 mL | 400 mL | 2000 mL | 3750 mL |

| Optimal blending volume | 5-50 mL | 50-300 mL | 400-1500 mL | 400-3750 mL |

| Type of bag | Bag with full-page filter | |||

| Bag composition | Multilayer: reinforced multicoated complex | |||

| Type of filter | Microperforated | |||

| Filter porosity | 280 micrometers | |||

| Bag dimensions | 95 x 180 mm | 190 x 300 mm | 250 x 380 mm | 380 x 600 mm |

| Gamma ray treated | 5 to 12 KGy | |||

| Average shelf-life | 15 years | |||

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) | |||

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) | |||

| Approved for food contact | Regulation (EC) N° 1935/2004 | |||

| Storage conditions | In a temperate and dry place, away from humidity and light | In a temperate and dry place, away from humidity and light | In a temperate and dry place, away from humidity and light | In a temperate and dry place, away from humidity and light |

| Box (w x d x h) | 35 x 21 x 11 cm | 34 x 22 x 26 cm | 48 x 29 x 14 cm | 41 x 34 x 12 cm |

| Gross weight | 1.9 kg | 5.9 kg | 5 kg | 4.8 kg |

| Pack of | 25 | 25 | 25 | 10 |

| Box of | 500 | 500 | 250 | 100 |

Unique bag for a full analysis

With BagPage, use the same bag to sample, blend, filter and pipet. This will prevent cross-contaminations and save time.

1. Insert the sample

2. Dilute the sample

3. Blend the sample

4. Pipet the filtrate

Handy

BagPage is a filter bag that simplifies the pipetting of the filtrate. Pipetting is debris-free thanks to the integrated microperforated filter. A special weld indicates where to pipet.

Instant filtration

Filtration is done during blending. There is no need to wait for sedimentation of the debris to pipet.

The filtrate is particle-free, so there is no debris on the Petri dish. Reading is thus facilitated and the results more precise.

No blocked pipet from articles

Debris free

No cross-contaminations

There is no contact between the sample and the mixer during homogenization. This avoids cross-contamination.

The bag can be closed with a BagClip or welded. It is processed by gamma ray.

Before

After

Applications

BagPage + adapts itself to every stage of sample preparation. Depending on the protocols, it is used in the food, pharmaceutical, cosmetic, environmental, animal health and public institutes:

- BagPage + 100 mL allows the preparation of small samples (1 to 10 g) in the pharmaceutical industries, cosmetics or animal health (Biopsy preparation).

- BagPage + 400 mL is suitable for samples of 25 g in the food industry.

- BagPage + 2000 mL is ideal for the search for Salmonella via the PCR method for example. It is also used for sample preparation up to 1500 mL with a test portion of 100 / 150g.

- BagPage + 3500 mL is particularly used in the food industry for sample pooling with a sample size up to 375 g.

BagPage – Full-page filter bags: Overview of the range

BagPage F

BagPage F

Full-page filter bag

Ref 122 325 (400 mL)

BagPage F is a blender bag with a full-page non-woven filter. Filtration is instant with no risk of cross-contamination. BagPage F, with its low porosity filter, is ideal for PCR analyses and flow cytometry.

- Filter porosity: < 60 micrometers

- Compatible with any laboratory blender

- Multilayer: reinforced multicoated complex

- Rigid and transparent

SPECIFICATIONS

| BagPage F 400 | |

| Reference | 122 325 |

| Ideal | For flow cytometry, PCR |

| Max blending volume | 400 mL |

| Optimal blending volume | 50-300 mL |

| Type of bag | Bag with full-page filter |

| Bag composition | Multilayer : reinforced multicoated complex |

| Type of filter | non-woven |

| Filter porosity | < 60 micrometers |

| Bag dimensions | 190 x 300 mm |

| Gamma ray treated | 5 to 12 KGy |

| Average shelf-life | 15 years |

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) |

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) |

| Approved for food contact | Regulation (EC) N° 1935/2004 |

| Storage conditions | In a temperate and dry place, away from humidity and light |

| Box (w x d x h) | 34 x 22 x 26 cm |

| Gross weight | 5.9 kg |

| Pack of | 25 |

| Box of | 500 |

Unique bag for a full analysis

With BagPage, use the same bag to sample, blend, filter and pipet. This will prevent cross-contaminations and save time.

1. Insert the sample

2. Dilute the sample

3. Blend the sample

4. Pipet the filtrate

Low porosity filter

BagPage F is equipped with a full-page low porosity non-woven filter. The porosity of the filter is < 60 micrometers. BagPage F is ideal for PCR, flow cytometry analyses.

Low porosity filter < 60 µm

Handy

BagPage is a filter bag that simplifies the pipetting of the filtrate. Pipetting is debris-free thanks to the integrated microperforated filter. A special weld indicates where to pipet.

Instant filtration

Filtration is done during blending. There is no need to wait for sedimentation of the debris to pipet.

The filtrate is particle-free, so there is no debris on the Petri dish. Reading is thus facilitated and the results more precise.

No blocked pipet from particles

Debris free

No cross-contaminations

There is no contact between the sample and the mixer during homogenization. This avoids cross-contamination.

The bag can be closed with a BagClip or welded. It is processed by gamma ray.

Before

After

Applications

BagPage F is useful according to protocols in microbiological analyses in the food, pharmaceutical, cosmetic, environmental and public research institutes. BagPage F is suitable for analyzes such as flow cytometry and PCR.

BagPage – Full-page filter bags: Overview of the range

BagPage R

BagPage R

Full-page filter bag

Ref 161 025 (400 mL)

BagPage R is a blender bag with a non-woven full-page filter. Filtration is instantaneous without risk of cross contamination. BagPage R is especially deisgned for pasty samples.

- Filter porosity: < 250 micrometers

- Compatible with any laboratory blender

- Multilayer: reinforced multicoated complex

- Rigid and transparent

SPECIFICATIONS

| BagPage R 400 | |

| Reference | 161 025 |

| Ideal | For homogenizing pasty samples |

| Max blending volume | 400 mL |

| Optimal blending volume | 50-300 mL |

| Type of bag | Non-woven full-page filter |

| Bag composition | Multilayer: reinforced multicoated complex |

| Type of filter | Microperforate |

| Filter porosity | < 250 micrometers |

| Bag dimensions | 190 x 300 mm |

| Gamma ray treated | 5 to 12 KGy |

| Average shelf-life | 15 years |

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) |

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) |

| Approved for food contact | Regulation (EC) N° 1935/2004 |

| Storage conditions | In a temperate and dry place, away from humidity and light |

| Box (w x d x h) | 34 x 22 x 26 cm |

| Gross weight | 5.7 kg |

| Pack of | 25 |

| Box of | 500 |

Unique bag for a full analysis

With BagPage, use the same bag to sample, blend, filter and pipet. This will prevent cross-contaminations and save time.

1. Insert the sample

2. Dilute the sample

3. Blend the sample

4. Pipet the filtrate

Ideal for pasty samples

BagPage R is equipped with a non-woven full-page filter adapted for the analysis of pasty samples (chocolate, cakes, cheese…).

Handy

BagPage R simplifies the pipetting step as the filtrate is without debris thanks to the non-woven filter. A special weld enables to be sure where to pipet.

Instant filtration

Filtration is done during blending. There is no need to wait for sedimentation of the debris to pipet.

The filtrate is particle-free, so there is no debris on the Petri dish. Reading is thus facilitated and the results more precise.

No blocked pipet from particles

Debris free

No cross-contaminations

There is no contact between the sample and the mixer during homogenization. This avoids cross-contamination.

The bag can be closed with a BagClip or welded. It is processed by gamma ray.

Before

After

Applications

BagPage R is useful according to protocols in microbiological analyses in the food, pharmaceutical, cosmetic, environmental and public research institutes. It adapts itself to every step of sample preparation.

BagPage – Full-page filter bags: Overview of the range

BagPage XR

BagPage XR

Full-page filter bag

Ref 122 425 (400 mL)

BagPage XR is a blender bag with a full-page microperforated filter. Filtration is instantaneous without risk of cross contamination. BagPage XR is extra resistant. It was designed for very hard samples (nuts, cockles, seafood, soil…).

- Filter porosity: 280 micrometers

- Compatible with any laboratory blender

- Multilayer: reinforced multicoated complex

- Extra resistant material: 50% thicker

SPECIFICATIONS

| BagPage XR 400 | |

| Reference | 122 425 |

| Ideal | For homogenizing very hard samples or for long blendings |

| Max blending volume | 400 mL |

| Optimal blending volume | 50-300 mL |

| Type of bag | Bag with full-page filter |

| Bag composition | Multilayer : reinforced multicoated complex |

| Type of filter | Microperforated |

| Filter porosity | 280 micrometers |

| Bag dimensions | 190 x 300 mm |

| Gamma ray treated | 5 to 12 KGy |

| Average shelf-life | 15 years |

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) |

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) |

| Approved for food contact | Regulation (EC) N° 1935/2004 |

| Storage conditions | In a temperate and dry place, away from humidity and light |

| Box (w x d x h) | 34 x 22 x 26 cm |

| Gross weight | 6.7 kg |

| Pack of | 25 |

| Box of | 400 |

Unique bag for a full analysis

With BagPage, use the same bag to sample, blend, filter and pipet. This will prevent cross-contaminations and save time.

1. Insert the sample

2. Dilute the sample

3. Blend the sample

4. Pipet the filtrate

eXtra Resistant

BagPage XR has been especially designed for very hard samples and/or long blendings. It is made of a 50% thicker material.

It is particularly suitable for environmental analyses (soil…), seafood analyses, dry products analyses (nuts, seeds…), difficult to process with conventional bags, subject to piercing during these analyses.

Handy

BagPage is a filter bag that simplifies the pipetting of the filtrate. Pipetting is debris-free thanks to the integrated microperforated filter. A special weld indicates where to pipet.

Instant filtration

Filtration is done during blending. There is no need to wait for sedimentation of the debris to pipet.

The filtrate is particle-free, so there is no debris on the Petri dish. Reading is thus facilitated and the results more precise.

No blocked pipet from particles

Debris free

No cross-contaminations

There is no contact between the sample and the mixer during homogenization. This avoids cross-contamination.

The bag can be closed with a BagClip or welded. It is processed by gamma ray.

Before

After

Applications

BagPage XR is useful according to protocols in microbiological analyses in the food, pharmaceutical, cosmetic, environmental and public research institutes. It adapts itself to every step of sample preparation.

BagPage – Full-page filter bags: Overview of the range