Automatic Viscometers

Petroleum Test and Oil Test Equipment

- Houillon Viscometer - S-Flow IV+ Kinematic

- U-Visc Kinematic Viscometer

- BitUVisc Kinematic Viscometer

- S-Flow Houillon Viscometer

S-flow IV⁺ Kinematic Viscometer

Houillon viscosity reinvented with an optional autosampler

U-Visc kinematic viscometer

Full range automatic viscometry systems for lubricants and other petroleum products

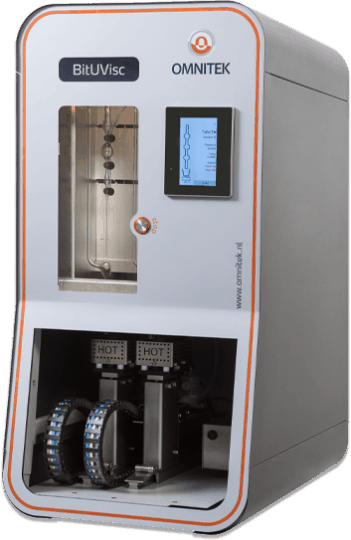

BitUVisc kinematic viscometer

Fully automatic viscometer for highly viscous samples up to 120,000 mm²/s

S-flow Houillon viscometer

Kinematic viscometry system for petroleum products

S-flow IV⁺ Kinematic Viscometer

“The newest generation of S-flow systems offers the ultimate in fast, accurate viscosity testing and now also features an optional autosampler for fully unattended operation.”

Maximum throughput and ease of use with very low sample and solvent consumption

The latest generation of new S-flow builds on the strong foundation of its predecessors to offer the ultimate in automatic viscosity testing of Newtonian samples such as petroleum products. The system offers all the tried and tested advantages of a Houillon-type tube design such as short process times, small sample volume and low solvent consumption, but now also includes an optional autosampler to allow for fully unattended operation. All controlled from a central user interface that takes care of result storage, autosampler control, VI calculations and much more. It complies fully with ASTM D7279 and as such, provides full correlation to ASTM D445. It is the ideal system for used oil analysis labs that need to test a wide range of lubricant viscosities.

The new S-flow IV+ consists of a 2 bath system with 2 tubes in each bath, providing a total of 4 tubes. The baths were designed to work independently, making it possible to use both baths at the same temperature, or at different temperature, ranging from 20°C to 120°C. Other options include dual solvent cleaning and integrated duplo testing which obtains 2 flow time determinations with only 1 sample injection.

All measurement parameters, such as warmup times and cleaning parameters can be set through the high resolution 12” touchscreen or with optional PC software. The diagnostic system alerts the operator to possible issues such as empty solvent supply tanks, full waste bottles and other potential issues. The optional auto-sampler is fully modular and in-field upgradeable, meaning you can purchase the analyser first and then upgrade to auto-sampling when the need arises.

Features | S-flow IV+ |

| Number of baths | 2 |

| Viscometers per bath | 2 |

| Standard methods | Compliant with ASTM D7279, D2270 Correlation with ASTM D445 |

| Built-in VI calculation | Yes |

| Measuring range | 0.3 – 3,000 mm2/s @40°C |

| Temperature range | 20 – 120°C * |

| Temperature stability | Better than ±0.02°C |

| Timer resolution | 0.001 s |

| Sample volume | 0.3 – 1.0 ml |

| Solvent consumption | 2 – 3 ml per cycle |

| Samples per hour | Up to 80 samples per hour ** |

| Viscometer type | Houillon |

| Sensor type | Optical, self-calibrating |

| Time measurement | Automatic |

| Solvent injection | Automatic |

| Advanced PC software option | Yes |

| Dual solvent option | Yes |

| Duplo measurement option | Yes |

| External cooling system option | Yes |

| Air compressor | Yes |

| Silicone oil option | Yes |

| Integrated cleaning pump | Yes |

| Warmup prior to measuring | Yes |

| Touchscreen | 12” capacitive |

| Optional autosampler | Yes |

| Dimensions | 40 x 58 x 66 cm (w x d x h) |

| Weight | 52 kg |

| Data export | USB storage device |

| Power requirement | 950 W; 115/240V – 50/60Hz |

* For temperatures around ambient, an external chiller is required

** Measurements per hour; depends on viscosity, tube, temperature and solvents

Optional accessories & upgrades

Following items are optional accessories and upgrades to the instrument.

Dual solvent cleaning

A suitable solvent used for cleaning should have the following two main characteristics:

- It should be able to dissolve the sample that was tested, i.e. clean the tube completely

- It should evaporate quickly enough at the bath temperature so that the tube is fully dry after cleaning

If the solvent used does have the ability to dissolve the sample, but does not evaporate quickly enough, a second solvent can be used to rinse out the first solvent, as well as dry the tube. Usually, low boiling solvents are used for this purpose, such as Acetone or MEK.

Cooling circulator

For measurements close to ambient (± 8°C), an additional cooling circulator is required to create sufficient offset for the temperature control unit. Each bath is fitted with a cooling spiral, to which an external cooling circulator can be easily connected. Complete with tubing and fittings.

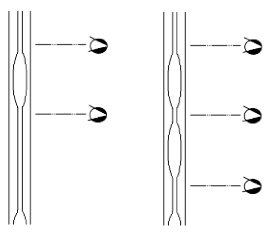

Single Duplo

Duplo measurement tubes

The optional duplo measurement configuration adds another array of optical detections to the instrument, bringing the total number of detection points to three per tube instead of two. Together with adapted S-flow IV tubes, which are fitted with two measuring trajectories, this enables the S-flow IV+ to perform duplo measurements with a single sample injection, increasing productivity, saving even more on solvent consumption and run time.

Compressor

Omnitek S-flow IV+ operate on clean and dry 5 bar @ 5 l/min of compressed air. A suitable compressor can be supply from Omnitek if no compressed air is available.

Positive – displacement pipette

Air-displacement pipette is supplied with S-flow IV+ as a standard. It is recommended to use positive displacement pipette especially at higher viscosities (300 mm2/s and above) to avoid operator errors and for more accurate and repeatable injections.

Software

Omnitek S-flow IV+ utilizes advanced and easy to use multi-lingual software, it can be operated directly from the touchscreen, and both calibration and viscosity measurements can be performed without PC or software. However, to have more control, dedicated optional software is available, which can be used to control multiple systems.

PC

A PC system can be sourced locally or through Omnitek. Omnitek supplies the latest model entry level laptop or, if required, desktop. When sourcing locally, make sure the operating system is Windows 7 or later and that the PC/Laptop has 1 free USB port per instrument.

Printer

Any kind of printer can be used if instrument is connected to a PC via software. A printer can be sourced locally or through Omnitek. Omnitek supplies the latest model entry level laser printer.

Autosampler operation

Omnitek offers autosampler operation for S-flow IV+. It is ideal for customers that run large numbers of samples and want to automate their sampling process. As each laboratory will have its own requirements, automation is a highly customized product which requires elaborate preparation. The autosampler stands out for being a modular high speed autosampler, it can be in-field upgradeable, services up to 2 S-flow IV+ instruments (8 tubes), processes 25-40 samples per hour and it is customizable to allow different sample cups and racks.

Please contact us for specific solutions to your sampling needs.

Thermometers

The customer should have a DCT shaft diameter < 3mm. The recommended thermometers that can be supplied are the modern digital contact thermometers (DCT), used at multiple temperatures

Features

- Applicable for fuels, base oils, formulated oils, and petroleum products as well as water-based fluids

- Compliant with requirements for ASTM D7279, ASTM 2270 and correlation to ASTM D445

- High throughput: up to 80 samples per hour under ideal operation conditions

- Very easy to use and maintain

- Small sample volume: 0.3 – 1.0 ml

- Low solvent consumption: 2 – 3 ml per sample.

- Extremely accurate temperature control and flow-time measurement independent of fluid type

- Automatic calibration of the optic amplifiers

- Automatic flow time measurement with ultraprecise meniscus detection

- Fully automatic cleaning and drying

- Fast & easy tube replacement (tubes are not connected to optical sensors)

- No need to drain bath during tube replacement.

- Single or dual solvent injection (optional)

- Measurement at 2 temperatures in 1 system simultaneously

- Integrated VI calculations

- Stand-alone unit. No PC required.

- Chemically resistant to allow for all common solvents

- Bath scheduler to turn baths on/off on preset times

- Bath temperature graphs on screen

- Bath backlight. It improves visibility of viscometer tubes and sensors

- User Access Control

- Duplo measurement capability

- Integrated back flushing

- Optional autosampler

This product is compliant with the following test methods:

- ASTM D7279

- ASTM D2270

This product is correlating with the following test method:

- ASTM D445

Industries | Petroleum Based Samples | Other Sample Types |

Refineries | Lubricating Oils | Printer ink |

Terminals (Fuel Distribution) | Additives | Gelatins |

| Lubricant Manufacturers | Base Stocks | |

Additive Manufacturers | Industrial Oils | |

Condition Monitoring Labs | Transmission Oils | |

Third Party Testing Labs | Hydraulic Fluids | |

Research & Development Labs | Used Oils | |

Quality Control Labs | Waste Oils | |

Military Labs | Crude Oils | |

Power Plants | Fuel Oils | |

Mines | Gasoline | |

Customs | Diesel | |

Universities | Bio Fuels | |

Automotive | Marine Fuels | |

Chemical Plants |

| |

Iron & Steel | ||

Textile | ||

Aviation | ||

Railways | ||

| Highways |

For other fluids / solutions please send your inquire

U-Visc kinematic viscometer

“The U-Visc viscometry system was designed with full ASTM D445 compliance in mind, combined with low solvent consumption, high unattended throughput, ease of use and reliability”.

The Omnitek U-Visc is the next generation of completely automatic viscometry systems.

The system combines several unique features, making it the instrument of choice in many applications, ranging from QC to R&D to used oil analysis. While offering full compliance with ASTM D445/446, the specially designed viscometer tubes cover a 100-fold range, e.g. from 1 to 100 mm2/s. The tubes are based on the well-known and proven Ubbelohde design, but only require 8-16 ml of sample and approx. 12-15 ml of solvent for cleaning. Available with single or dual solvent cleaning, the instrument measures kinematic viscosity in Newtonian fluids like lubricants, fuels or dissolved plastics between 0.15 and 25,000 mm2/s.

Designed to be versatile and flexible, yet easy use. Different models are available range from 1 bath with 1 or 2 viscometer tubes, up to 2 baths with 1 or 2 viscometer tubes per bath, where ach bath works independently. Sophisticated temperature control ensures that measurements are carried out well within limits specified by ASTM D445. Each bath features a 32-position sampling tray (16 samples per tube), allowing completely unattended operation. Depending on the viscosity of the sample, the instrument can process up to 40 measurements per hour, satisfying even the needs of high volume labs running several hundred samples per day.

Samples can be introduced using vacuum or pressure. The latter avoids evaporation of sample, which can be a point of concern in some dilute viscosity applications. Viscometers are easily exchanged in minutes instead of hours, minimizing downtime. All surfaces of the viscometer tubes, including the outside bottom, which is in contact with the sample, are thoroughly cleaned and dried using solvents and air.

Features | U-Visc 110 / 120 / 210 / 220 |

| Measuring range | 0.15 – 25,000 mm2/s @ 40°C |

| Temperature range | 15 – 150°C * |

Temperature stability | 15°C to 100°C ± 0.01°C * |

Timer accuracy | 0.001 s |

Sample volume | 8 ml – 16 ml |

Sample introduction | Vacuum / Pressure |

Solvent consumption | 10 – 12 ml per cycle / 12 – 15 ml per cycle (single / dual) |

Sample throughput | U-Visc 110: up to 10 measurements per hour ** U-Visc 120: up to 20 measurements per hour ** U-Visc 210: up to 20 measurements per hour ** U-Visc 220: up to 40 measurements per hour ** |

Applicable standards | ASTM D445, D446, D2270, ISO3104, ISO3105, IP 71, ISO 2909, DIN 51562. |

Viscometer type | Ubbelohde based |

Sensor type | Thermal / Optical |

Optional preheater | Yes |

Optional duplo measurement | Yes |

Dual Solvent cleaning | Yes |

Communication | RS-232C |

PC software | Yes |

PC control | Multiple instruments controlled with 1 PC |

Data Export | USB storage device |

Dimensions / Weight | U-Visc 110 / 120: 38 x 62 x 78 cm (w x d x h) / 54 kg (empty) U-Visc 210 / 220: 75 x 62 x 78 cm (w x d x h) / 92 kg (empty) |

Power requirement | U-Visc 110 / 120: 10A @ 230 V U-Visc 210/ 220: 16A @ 230 V |

* For temperatures around ambient, an external chiller is required

** Measurements per hour; depends on viscosity, tube, temperature and solvents

Optional accessories & upgrades

Following items are optional accessories and upgrades to the instrument.

Sample pre-heater

All U-Visc versions can be equipped with a sample pre-heater unit suitable to heat up fluids and solids from ambient up to 120 °C (controllable). Sample pre-heating is applicable to every tube, so ultimately a U-Visc 220 may be equipped with 4 sample pre-heaters.

Cooling circulator

For measurements close to ambient (± 8°C), an additional cooling circulator is required to create sufficient offset for the temperature control unit. Baths contain cooling spiral, to which an external cooling circulator can be easily connected. Complete with tubing and fittings. Cooling circulator will be supplied separately on request.

Compressor

Omnitek U-Visc systems operate on clean 5 bar compressed air. If not available on-site, you require a stand-alone version with minimum 5 bar @ 5 l/min for the U-Visc 100 series and @ 7.5 l/min for the U-Visc 200 series.

Pedestal base

Pedestal base can be supplied from Omnitek for floor-standing installation.

PC & Printer

Any kind of PC can be used. PC can be supplied locally or from Omnitek. Omnitek supplies a new generation laptop. Minimum operation software should be Windows 7. PC should have RS232 or USB port (RS-232 adapter comes with Omnitek software).

Any kind of printer can be used if instrument is connected to a PC by software. Printer can be supplied locally or from Omnitek. Omnitek supplies the latest model laser printer.

ASTM Thermometers

All U-Visc units can be equipped with ASTM thermometers. The recommended thermometers that can be supplied are the modern digital contact thermometers (DCT), used at multiple temperatures.

Features

- Applicable for fuels, base oils, formulated oils, and other petroleum products.

- Fully automatic

- Sample carrousel

- Meets all ASTM, EN, ISO and DIN standards related to kinematic viscosity

- Extremely accurate temperature control

- Extremely accurate flow-time measurement independent of fluid type

- Viscometer filling by either vacuum or pressure method

- Little sample volume / little solvent consumption

- High throughput; up to 10 measurements per bath per tube per hour

- Innovative viscometer tube cleaning allowing cross contamination free operation

- Easy viscometer tube exchange

- Suitable for petrochemical fluids and diluted solution viscosity samples

- Chemically resistant to an extended range of fluids and solvents

- Multiple versions available covering a wide variety of requirements

- Compact design

- Optional duplo viscometer tubes for unstable samples

This product is compliant with the following test methods:

- ASTM D445

- ASTM D446

- DIN 3104

- DIN 3105

- IP 71

Industries | Petroleum Based Samples | Other Sample Types |

Refineries | Lubricating Oils | Fatty Acids |

Terminals (Fuel Distribution) | Additives | |

| Lubricant Manufacturers | Base Stocks | |

Additive Manufacturers | Industrial Oils | |

Condition Monitoring Labs | Transmission Oils | |

Third Party Testing Labs | Hydraulic Fluids | |

Research & Development Labs | Used Oils | |

Quality Control Labs | Waste Oils | |

Military Labs | Crude Oils | |

Power Plants | Fuel Oils | |

Mines | Gasoline | |

Customs | Diesel | |

| Universities | Bio Fuels | |

Automotive | Marine Fuels | |

Chemical Plants | Waxy samples | |

Iron & Steel | ||

Pulp & Paper | ||

Textile | ||

Aviation | ||

| Railways |

| |

| Highways |

|

For other fluids / solutions please send your inquire

BitUVisc kinematic viscometer

“Finally an instrument that eliminates the need for the tedious, labour intensive manual loading, measurement and cleaning of high viscosity samples”.

Omnitek ‘BitUVisc’ is a programmable, fully automatic kinematic viscometer specially designed to handle highly viscous samples at high temperatures.

The system can process samples with viscosities ranging up to 120,000 mm2/s, up to 150°C. It fully complies with ASTM D445, D446, D2170 and AASHTO T201.

There are 2 different models available: 110 and 120. BitUVisc 110 features a single thermostatic bath with 1 viscometer tube whereas BitUVisc 120 model holds 2 viscometer tubes in a single bath. All BitUVisc instruments are equipped with auto-sampling, preheating, fully automatic dual solvent cleaning and drying.

Viscometer tubes are based on the well-known and proven Ubbelohde design. Using specially designed thermal sensors, these tubes allow the detection of fully opaque fluids without any problems or limitations and eliminate the need to use the reverse flow tubes. The standard configuration offers viscosity measurement up to 150°C and sample preheating up to 200°C.

Sophisticated temperature control ensures that measurements are carried out well within the required temperature stability. The system features an innovative single position auto-sampling which provides integrated heating of the sample up to 200°C and uses preheated solvent to effectively clean the viscometer tube. The BitUVisc is fitted with special designed duplo viscometer tubes for unstable samples such as vacuum residues, additives, crude oils, waxes, heavy fuel oils, polymers, asphalts, etc., which typically show poor determinability when sampled repeatedly. These tubes have 2 measuring sections with an approximately similar tube constant. This allows for an actual duplo determination while only sampling once.

Features | BitUVisc 110 / 120 |

| Measuring range | Up to 120,000 mm2/s, up to 150°C |

| Temperature range | 15 – 150°C * |

| Temperature stability | 15°C to 100°C ± 0.01°C * Up to 150°C, ± 0.03°C |

Preheater temperature | Up to 200°C |

Timer accuracy | 0.001 s |

Sample volume | 12 ml |

Sample introduction | Vacuum |

Solvent consumption | 10 – 30 ml per cycle, sample dependent |

Sample throughput | BitUVisc 110: up to 2 measurements per hour ** BitUVisc 120: up to 4 measurements per hour ** |

Applicable standards | ASTM D445/D446, ASTM D2170 |

Viscometer type | Ubbelohde based |

Duplo Measurement | Yes |

Sensor type | Thermal |

Built-in preheater | Yes |

Dual Solvent cleaning | Yes |

Communication | RS-232C |

PC software | Yes |

PC Control | Multiple instruments controlled with 1 PC |

Data Export | USB storage device |

Dimensions | 110 / 120: 38 x 62 x 78 cm (w x d x h) |

Weight | 54 kg (empty) |

Power requirement | 10A @ 230 V |

* For temperatures around ambient, an external cooling circulator is required

** Measurements per/hour; depends on viscosity, tube constant, temperature and solvents chosen. Measurement cycles are given for a sample with a viscosity around 50.000 mm2/s @ 40°C.

BitUVisc series optional accessories

The following items are optional accessories and upgrades to the instrument.

Cooling circulator

For measurements, close to ambient (± 8°C), an additional cooling circulator is required to create sufficient offset for the temperature control unit. The bath needs to be fitted with a cooling spiral, to which an external cooling circulator can be easily connected. Complete with tubing and fittings. Cooling circulator will be supplied separately on request.

Compressor

Omnitek BitUVisc systems operate on clean 5 bar compressed air. If not available on-site a stand-alone version with @ approx. 5 l/min.

Pedestal base

Pedestal base can be supplied from Omnitek for floor-standing installation.

PC & Printer

PC can be supplied locally or from Omnitek. Omnitek supplies a new generation laptop. Minimum operation software should be Windows 7.

Any kind of printer can be used if instrument is connected to a PC by software. Printer can be supplied locally or from Omnitek. Omnitek supplies the latest model laser printer.

ASTM Thermometers

All BitUVisc units can be equipped with ASTM thermometers. The recommended thermometers that can be supplied are the modern digital contact thermometers (DCT), used at multiple temperatures.

Glass sample cups

For temperature above 105°C, glass sample cups are required for the sample measurement.

Features

- Applicable for fuels, base oils, formulated oils, highly viscous samples like vacuum residues, additives, crude oilswaxes, heavy fuel oils, polymers, asphalts, etc.

- Meets all ASTM, EN, ISO, DIN, AASHTO T201, EN 12595 and standards related to kinematic viscosity standards

- Extremely accurate temperature control

- Extremely accurate flow-time measurement independent of fluid type

- Viscometer filling by vacuum method

- Innovative and efficient viscometer tube cleaning allowing cross contamination free operation

- Easy viscometer tube exchange

- Chemically resistant to an extended range of fluids and solvents

- Compact design

This product is compliant with the following test methods:

- ASTM D445

- ASTM D446

- ASTM D2170

- AASHTO T201

- EN 12595

Industries | Samples |

| Refineries Bitumen (Asphalt Plants) | Heavy Fuel Oils (HFO) |

Road Construction & Paving | Residual Fuel Oils (RFO) |

Additive Manufacturers | Vacuum Residues |

Lubricant Manufacturers | Bitumens (Asphalts) |

Third Party Labs | Waxy samples |

Research & Development Labs | Lubricating oils |

Quality Control Labs | Additives |

For other fluids / solutions please send your inquire

S-flow Houillon viscometer

“The S-flow system was designed for maximum throughput and ease of use while minimizing sample quantity and solvent consumption. It is the ideal viscometer for quick and accurate results”.

Maximum throughput and ease of use with very low sample and solvent consumption

The S-flow range of instruments consist of compact, bench-top automated viscometry systems for the analysis of Newtonian fluids. It complies fully with in ASTM D7279 and as such, has a direct correlation with ASTM D445. It is the ideal system for used oil analysis labs that need to test a wide range of lubricant viscosities. Quick analysis time, small sample size and low solvent consumption, combined with extreme ease of use and reliability make it the instrument of choice for many of our world-wide users.

The S-flow system is a self-contained viscometer system that consists of an accurately controlled thermostatic bath and a control touchscreen. Different models are available with either 1 or 2 baths, each of which contains 4 Houillon style tubes. Highly accurate optical sensors detect the flow of the sample through the viscometer tubes to obtain flow time results with 0.001 sec. precision. All measuring viscometer tubes function fully independently of each other allowing for very high throughput.

Additional parameters such as tube constants and cleaning cycle are also controlled by the operator. Only requiring 0.3 ml of sample, the system performs the measurement very quickly, allowing a throughput of up to 80 tests per hour per bath. Options include dual solvent cleaning and integrated duplo testing which allows the operator to perform 2 flow time determinations with only 1 sample injection.

Versions

Omnitek S-flow is available in 3 different models

S-flow 870

| S-flow 1250

| S-flow 3500

| |

| Numer of baths | 1 | 1 | 2 |

Viscometers per system | 4 | 4 | 8 |

Time measurement | Automatic | Automatic | Automatic |

Integrated cleaning pump | Yes | Yes | Yes |

Chemically resistant | Yes | Yes | Yes |

Solvent injection | Manual | Automatic | Automatic |

Software (optional) | Yes | Yes | Yes |

Integrated Viscosity Index | No | No | Yes |

Dual solvent option | No | Yes | Yes |

Duplo measurement option | Yes | Yes | Yes |

Samples per hour | 25-40 * | 40-80 * | 80-160 * |

Temperature range (°C) | 20-120 ** | 20-120 ** | 20-120 ** |

Integrated backflush | Yes | Yes | Yes |

Warmup prior to measuring | Yes | Yes | Yes |

Touchscreen | 7” | 7” | 10” |

Optional robotic operation | No | Yes | Yes |

* Samples per / hour; depends on viscosity, tube, temperature and solvents chosen

** For temperatures around ambient, an external chiller is required

S-flow series specifications

Feature | S-flow 870 / 1250 / 3500 |

Standard methods | Complies to ASTM D7279, D2270 and Correlates to ASTM D445 |

Measuring range | 0.3 – 3,000 mm2/s (cSt) @ 40°C |

Temperature range | 20 – 120°C * |

Temperature stability | Better than ± 0.02°C |

Timer resolution | 0.001 s |

Sample volume | 0.3 – 1.0 ml |

Solvent consumption | 2 – 3 ml per cycle |

Sample throughput | Up to 80 samples per hour per bath (S-flow 1250 and 3500 models) ** |

Viscometer type | Houillon |

Sensor type | Optical |

PC Control | Multiple instruments controlled with 1 PC |

Dimensions | 44 x 48 x 62 cm. Single bath models |

| Weight | 32 kg. Single bath models 62 kg. Double bath models |

Data export | USB storage device |

Power requirement | 2.5 kW; 115/240V – 50/60Hz. Single bath models |

* For temperatures around ambient, an external chiller is required

** In optimum conditions

Optional accessories & upgrades

Following items are optional accessories and upgrades to the instrument.

Dual solvent cleaning

A suitable solvent used for cleaning should have the following two main characteristics:

- It should be able to dissolve the sample that was tested, i.e. clean the tube completely

- It should evaporate quickly enough at the bath temperature so that the tube is fully dry after cleaning

If the solvent used does have the ability to dissolve the sample, but does not evaporate quickly enough, a second solvent can be used to rinse out the first solvent, as well as dry the tube. Usually, low boiling solvents are used for this purpose, such as Acetone or MEK.

Cooling spiral & cooling circulator

For measurements close to ambient (± 8°C), an additional cooling circulator is required to create sufficient offset for the temperature control unit. Each bath needs to be fitted with a cooling spiral, to which an external cooling circulator can be easily connected. Complete with tubing and fittings. Cooling spiral and cooling circulator will be supplied separately on request.

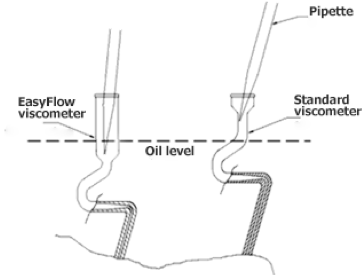

EasyFlow viscometers tubes

For high viscosity, EasyFlow can be great use. EasyFlow viscometers can be provided starting from tube constant 1.0.

Single Duplo

Duplo measurement tubes

The optional duplo measurement upgrade adds another array of optical fibers to the instrument, bringing the total number of detection points to three per tube instead of two. Together with adapted S-flow tubes, which are fitted with two measuring trajectories, this enables the S-flow 870, S-flow 1250 and the S-flow 3500 to perform duplo measurements with a single sample injection, increasing productivity, saving even more on solvent consumption and runtime.

Compressor

Omnitek S-flow systems operate on clean and dry 5 bar @ 5 l/min of compressed air. A suitable compressor can be supply from Omnitek if no compressed air is available.

Positive – displacement pipette

Air-displacement pipette is supplied with S-flow series as a standard. It is recommended to use positive displacement pipette especially at higher viscosities (300 mm2/s and above) to avoid operator errors and for more accurate and repeatable injections.

Software

All Omnitek S-flow systems utilizes advanced and easy to use multi-lingual software, it can be operated directly from the touchscreen, and both calibration and viscosity measurements can be performed without PC or software. However, to have more control, dedicated software is available, which can be used to control multiple systems.

PC

A PC system can be sourced locally or through Omnitek. Omnitek supplies the latest model entry level laptop or, if required, desktop. When sourcing locally, make sure the operating system is Windows 7 or later and that the PC/Laptop has 1 free USB port per instrument.

Printer

Any kind of printer can be used if instrument is connected to a PC via software. A printer can be sourced locally or through Omnitek. Omnitek supplies the latest model entry level laser printer.

Robotic Operation

Omnitek offers “Robotic Operation” for models S-flow 1250 and 3500 for customers that run large numbers of samples (>500 samples per day) and want to automate their sampling process. As each laboratory will have its own requirements, automation is a highly customized product which requires elaborate preparation. Please contact us for specific solutions to your sampling needs.

ASTM Thermometers

All S-flow units can be equipped with ASTM thermometers. The recommended thermometers that can be supplied are the modern digital contact thermometers (DCT), used at multiple temperatures.

Features

- Applicable for fuels, base oils, formulated oils, and petroleum products as well as water-based fluids.

- Compliant with requirements for ASTM D7279, ASTM 2270 and correlation to ASTM D445.

- High throughput: up to 80 samples per hour per bath under ideal operation conditions.

- Very easy to use and maintain.

- Small sample volume: 0.3-1.0 ml.

- Low solvent consumption: 2-3 ml per sample.

- Extremely accurate temperature control and flow-time measurement independent of fluid type.

- Automatic flow time measurement with ultraprecise meniscus detection.

- Fully automatic cleaning and drying (model dependent).

- Fast & easy tube replacement (tubes are not connected to optical sensors).

- No need to drain bath during tube replacement.

- Single or dual solvent injection (model dependent).

- Integrated VI calculations (on 3500 model only).

- Stand-alone unit. No PC required. Software operation is available as an option.

- Chemically resistant to allow for all common solvents.

- Optional duplo measurement capability.

- Integrated back flushing.

This product is compliant with the following test methods:

- ASTM D7279

- ASTM D2270

This product is correlating with the following test method:

- ASTM D445

Industries | Petroleum Based Samples | Other Sample Types |

Refineries | Lubricating Oils | Printer ink |

Terminals (Fuel Distribution) | Additives | Gelatins |

| Lubricant Manufacturers | Base Stocks | |

Additive Manufacturers | Industrial Oils | |

Condition Monitoring Labs | Transmission Oils | |

Third Party Testing Labs | Hydraulic Fluids | |

Research & Development Labs | Used Oils | |

Quality Control Labs | Waste Oils | |

Military Labs | Crude Oils | |

Power Plants | Fuel Oils | |

Mines | Gasoline | |

Customs | Diesel | |

Universities | Bio Fuels | |

Automotive | Marine Fuels | |

Chemical Plants |

| |

Iron & Steel | ||

Textile | ||

Aviation | ||

Railways | ||

| Highways |

For other fluids / solutions please send your inquire